Composite efficient phosphorus removal agent as well as preparation method and application thereof

A phosphorus removal agent and efficient technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve problems such as greater impact on biochemical systems, affecting water chroma, and low phosphorus removal efficiency , to achieve the effects of simple dosing system, easy precipitation and removal, and high phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

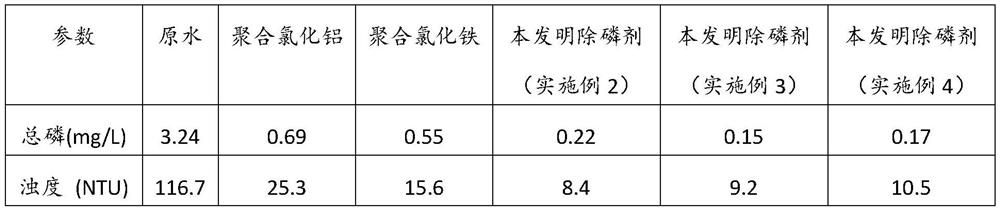

Examples

Embodiment 1

[0032] A composite high-efficiency phosphorus removal agent provided by the embodiment of the present invention comprises the following components and the mass ratio of the components is: 85-93 parts of inorganic salt solution, 0.5-1 part of adsorbent, 6-14 parts of coagulation aid and scrap iron Chips 0.05 to 0.1 part. Wherein: the inorganic salt solution is composed of at least any three and sodium carbonate in ferric sulfate, ferrous sulfate, ferrous chloride, aluminum sulfate, calcium chloride, magnesium sulfate, and wherein the mol ratio of iron and aluminum is controlled at 3: 1 to 5:1. The adsorbent is composed of any one or more of bentonite, diatomite and montmorillonite. The coagulation aid is composed of any one or both of polydimethyldiallyl ammonium chloride and polyepichlorohydrin amine and cetyltrimethylammonium chloride. Scrap iron filings are added to the composite high-efficiency phosphorus removal agent.

[0033] The method for preparing a composite high-...

Embodiment 2

[0041] A composite high-efficiency phosphorus removal agent comprises the following components and their mass ratios are: 87 parts of an inorganic salt solution, 0.8 part of an adsorbent, 12.15 parts of a coagulant aid and 0.05 part of scrap iron filings.

[0042] Wherein: the mass ratio of inorganic salt solution is, 5 parts of iron sulfate, 25 parts of ferrous sulfate, 10 parts of aluminum sulfate, 1 part of calcium chloride, 0.5 part of sodium carbonate, 58.5 parts of water are obtained, wherein the mole of iron and aluminum is obtained. The ratio is controlled at 3 to 5:1;

[0043] The mass ratio of the adsorbent is 1 part of bentonite and 1 part of diatomite;

[0044] The mass ratio of the coagulant aid is: 0.5 part of cetyltrimethyl ammonium chloride, 15 parts of polydimethyldiallyl ammonium chloride, and 84.5 parts of water.

[0045] A preparation method of a composite high-efficiency phosphorus removal agent is as follows:

[0046] Step 1, preparation of inorganic sa...

Embodiment 3

[0053] A composite high-efficiency phosphorus removal agent, comprising the following components and the mass ratio of the components: 90 parts of inorganic salt solution, 0.6 part of adsorbent, 9.35 parts of coagulation aid and 0.05 part of scrap iron filings.

[0054] Wherein: the mass ratio of the inorganic salt solution is 5 parts of ferric sulfate, 20 parts of ferrous sulfate, 7 parts of ferrous chloride, 10 parts of aluminum sulfate, 1 part of calcium chloride, 0.5 parts of sodium carbonate, and 56.5 parts of water, wherein The molar ratio of iron to aluminum is controlled at 3 to 5:1;

[0055] The mass ratio of the adsorbent is 1 part of diatomaceous earth; the mass ratio of the coagulant is: 0.5 part of cetyltrimethyl ammonium chloride, 10 part of polydimethyldiallyl ammonium chloride parts, 5 parts of polyepichlorohydrin, and 84.5 parts of water.

[0056] A preparation method of a composite high-efficiency phosphorus removal agent is as follows:

[0057] Step 1, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com