Adsorbent, Preparation and Application of Bacterial Cellulose Supported Lanthanum Metal Compounds

A technology of bacterial cellulose and metal compounds, applied in the direction of adsorption water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of secondary pollution, high cost, high requirements for reaction conditions, etc., and achieve mild reaction conditions , good load function, fast phosphorus removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the first step, 2 g of bacterial cellulose crude product is washed and filtered with tap water, and deionized water is added for sterilization in a water bath. With 3‰NaOH solution and 1.5‰H 2 o 2 Soak it in a water bath at 90°C for 2 hours to further purify the crude bacterial cellulose, then add HAc-NaAc buffer solution dropwise to neutralize and remove excess NaOH, and finally, filter and wash the product to obtain purified bacterial cellulose;

[0032] In the second step, 0.7g of lanthanum nitrate was dissolved in deionized water and stirred; then the purified bacterial cellulose obtained in the first step was added to it, and ultrasonically dispersed for 4h; under stirring condition, ammonia water was slowly added dropwise therein to adjust pH to 10.0;

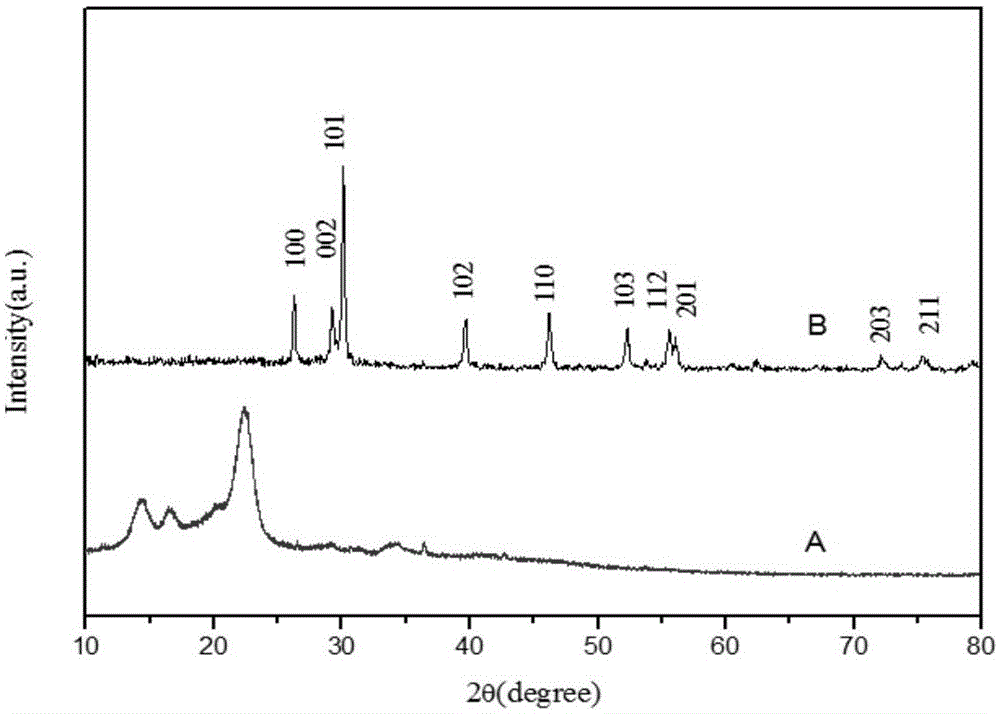

[0033] The third step is to transfer the product of the second step to a hydrothermal reaction kettle for hydrothermal reaction. The reaction temperature is 180°C and the reaction time is 16h. After the reacti...

Embodiment 2

[0035] In the first step, 2 g of bacterial cellulose crude product is washed and filtered with tap water, and deionized water is added for sterilization in a water bath. With 2.5‰NaOH solution and 1.5‰H 2 o 2 Soak it in a water bath at 80°C for 3 hours to further purify the crude bacterial cellulose, then add HAc-NaAc buffer solution dropwise to neutralize and remove excess NaOH, and finally, filter and wash the product to obtain purified bacterial cellulose;

[0036] In the second step, 0.82g of lanthanum nitrate was dissolved in deionized water and stirred; then the purified bacterial cellulose obtained in the first step was added to it, and ultrasonically dispersed for 3h; pH to 7.0;

[0037] The third step is to transfer the product of the second step into a hydrothermal reaction kettle for hydrothermal reaction. The reaction temperature is 200°C and the reaction time is 24h. The bacterial cellulose-loaded lanthanum metal compound adsorbent is obtained.

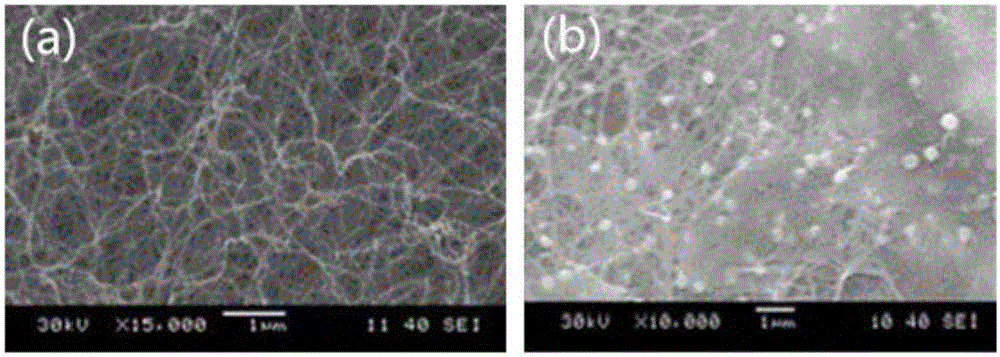

[0038] figur...

Embodiment 3

[0041] In the first step, 2 g of bacterial cellulose crude product is washed and filtered with tap water, and deionized water is added for sterilization in a water bath. With 3‰NaOH solution and 3‰H 2 o 2Soak it in a water bath at 80°C for 2 hours to further purify the crude bacterial cellulose, then add HAc-NaAc buffer solution dropwise to neutralize and remove excess NaOH, and finally, filter and wash the product to obtain purified bacterial cellulose;

[0042] In the second step, 0.6 g of lanthanum nitrate was dissolved in deionized water and stirred; then the purified bacterial cellulose obtained in the first step was added to it, and ultrasonically dispersed for 2 hours; under stirring conditions, ammonia water was slowly added dropwise therein to adjust pH to 8.0;

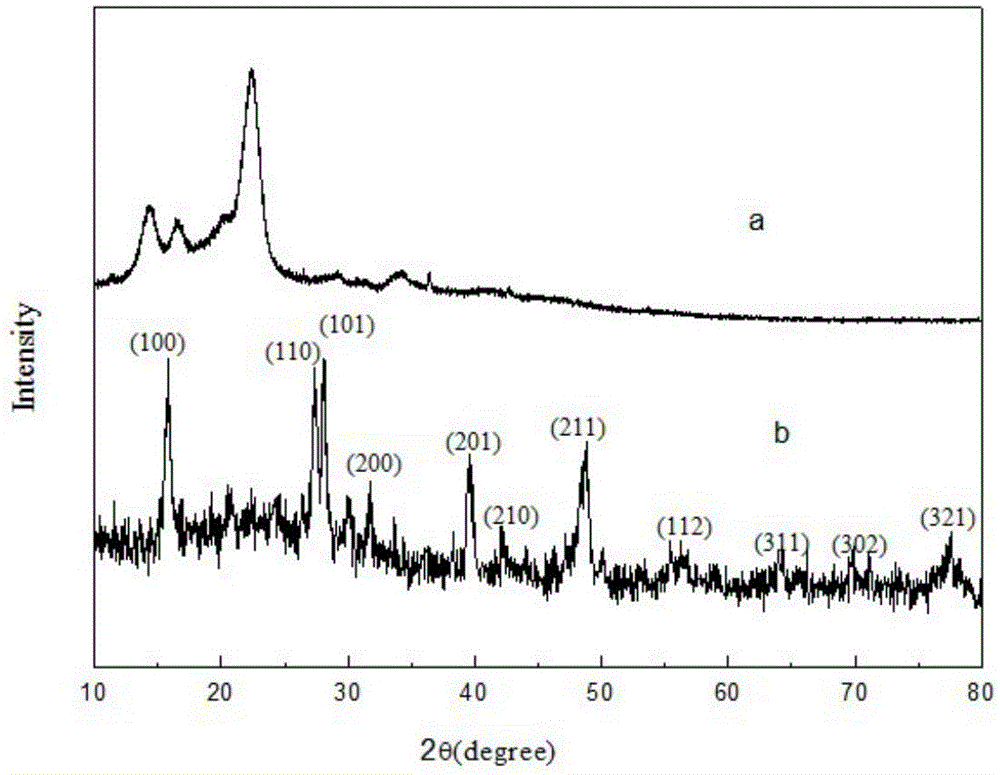

[0043] The third step is to transfer the product of the second step to a hydrothermal reaction kettle for hydrothermal reaction. The reaction temperature is 100°C and the reaction time is 12h. After the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com