Method and equipment for producing coated glass

A production method and technology for coated glass, which are applied in the field of production methods and production equipment for coated glass, can solve the problems of unevenness, low production efficiency, and large amount of coating liquid, and achieve the effects of stable quality and easy production and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] as attached Figure 9 As shown, a production equipment for coated glass, including a film loading machine A, a glass cleaning machine B, a glass preheating machine C, a glass coating machine D, a coating pre-curing machine E, and a coating high-temperature curing machine F arranged sequentially on the production line , Glass cooling machine G and unloading machine H.

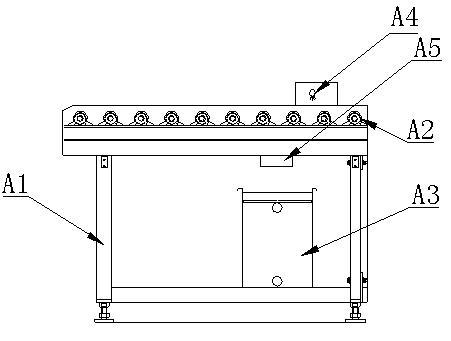

[0054] Among them, as attached figure 1 As shown, the composition of the loading machine A includes a support platform A1, a roller table A2 arranged on the support platform, a water circulation system A3 provided below the support platform, and a water spray system A4 connected to the water circulation system provided above the roller table And the water receiving funnel A5 arranged above the water circulation system A3.

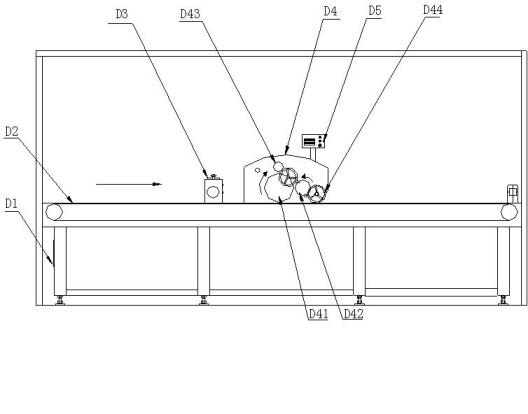

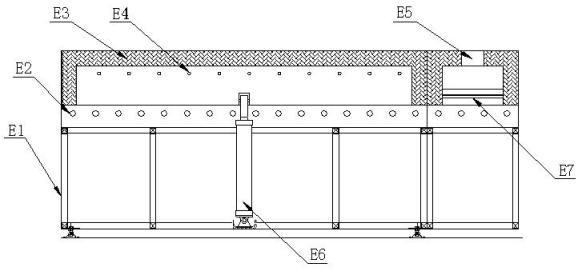

[0055] as attached figure 2 As shown, the glass cleaning machine B includes four cleaning units, wherein the first two cleaning units respectively include a support platform B1, a ...

Embodiment 2

[0064] Glass cleaning solution: JL-001B type cleaning solution (produced by Shenzhen Juwei Optical Electronic Material Co., Ltd.), which is paired with water at a ratio of 1:10 and used for cleaning treatment.

[0065] Glass coating machine: JL-1200G type coating machine (manufactured by Hangzhou Jieling Machinery Equipment Co., Ltd.).

[0066] Nano sol-gel liquid coating solution: JW-AR0812 type anti-reflection glass coating solution (produced by Shenzhen Juwei Optical Electronic Material Co., Ltd., mainly including nano-SiO 2 and a nanosol-gel liquid of ethylene glycol methyl ether, n-butanol and water as solvents).

[0067] Adopt the equipment of embodiment 1, according to as attached Figure 10 The shown process flow does the following:

[0068] The ultra-clear embossed flat glass is sent to the glass washing machine through the loading machine, after four-stage cleaning, and then air-cooled and dried, it is sent to the airtight buffer room of the glass washing machine, ...

Embodiment 3

[0071] Glass cleaning solution: JL-001B type cleaning solution (produced by Shenzhen Juwei Optical Electronic Material Co., Ltd.), which is paired with water at a ratio of 1:10 and used for cleaning treatment.

[0072] Glass coating machine: JL-1200G type coating machine (manufactured by Hangzhou Jieling Machinery Equipment Co., Ltd.).

[0073] Nano sol-gel liquid coating solution: JW-SL0719 heat-insulating glass coating solution (produced by Shenzhen Juwei Optical Electronic Material Co., Ltd., mainly including nano-SnO 2 and a nanosol-gel liquid of ethylene glycol methyl ether, n-butanol and water as solvents).

[0074] Adopt the equipment of embodiment 1, according to as attached Figure 10 The shown process flow does the following:

[0075] The flat glass is sent to the glass washing machine through the loading machine, after four-stage cleaning, and then air-cooled and dried, it is sent to the airtight buffer room of the glass washing machine, and then the cleaned glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com