Process for preparing hydrated sodium titanate and nano titanate tube series

A technology of hydrated sodium titanate and hydrated titanate, which is applied in chemical instruments and methods, titanium compounds, inorganic chemistry, etc., can solve the problems of complex production process, high price, limited application, etc., and overcome the problem of large particles and simple equipment , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation process of the present invention comprises the following three aspects:

[0031] 1. Preparation of hydrated sodium titanate nanotubes using titanium dioxide as raw material

[0032] The method for synthesizing hydrated sodium titanate nanotubes fully utilizes the properties of titanium dioxide as an acid anhydride, uses water as a medium, and reacts in NaOH concentrated solution.

[0033] Process steps: mix titanium dioxide with 3-15 mol / liter NaOH solution at a ratio of 0.5-3 g: 40 ml of solution, put them in a closed container, and conduct a hydrothermal reaction at 60-300°C for 3 hours to 8 days to obtain The product is washed with deionized water and dried to obtain nanotubes of hydrated sodium titanate.

[0034] Above-mentioned reaction is represented as follows with chemical equation:

[0035] (x=0.1-1)

[0036] 2. With metatitanic acid (H 2 TiO 3 ) as raw material to prepare hydrated sodium titanate nanotubes

[0037] The method for sy...

Embodiment 1

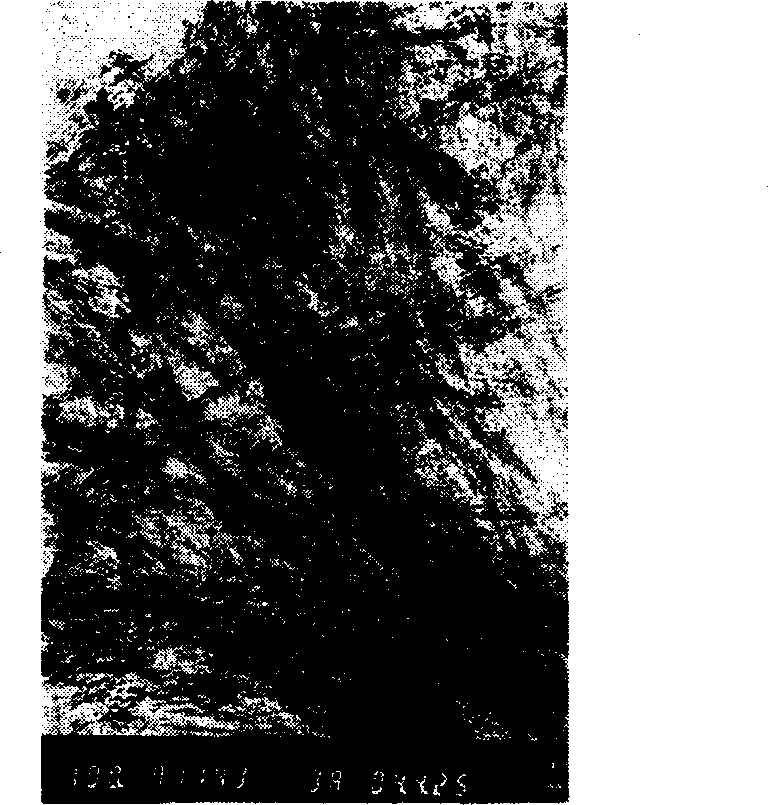

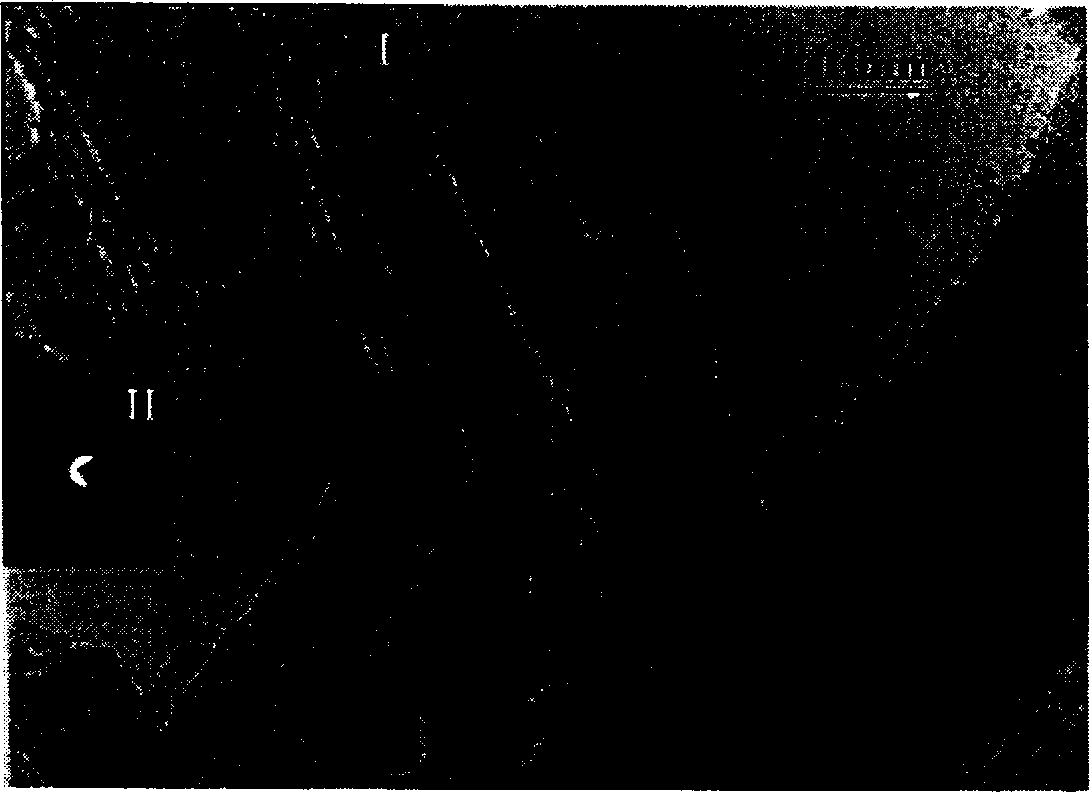

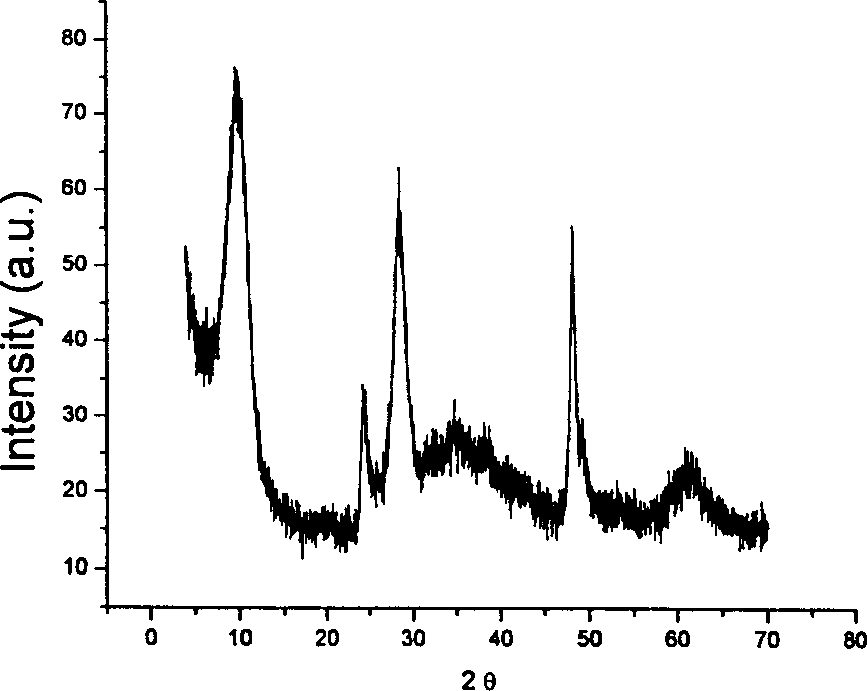

[0050] Embodiment 1: (titanium dioxide is the raw material preparation hydrated sodium titanate nanotube part)

[0051] Take 0.5 g of industrially produced titanium dioxide, add it to a 40 ml hydrothermal kettle, add 3 mol / L NaOH solution to the kettle, heat it at 300°C for 1 day, wash the white precipitate with deionized water, and dry it to obtain hydrated Nanotubes of sodium titanate salt. Its molecular formula can be expressed as: Na x h 2-x Ti 2 o 5 ·H 2 O(x=0.1-1)

[0052] Repeat the above operation steps, increase the concentration of lye to 15 mol / liter, heat at 300° C. for 3 hours, and obtain nanotubes of hydrated sodium titanate.

[0053] Repeat the above operation steps, increase the concentration of lye to 7 mol / liter, lower the temperature to 160° C., and heat in water for 3 days to obtain nanotubes of hydrated sodium titanate.

[0054] Repeat the above operation steps, increase the concentration of the lye to 15 mol / liter, lower the temperature to 60° C., ...

Embodiment 2

[0057] Embodiment 2: (preparation of hydrated sodium titanate nanotube part with metatitanic acid as raw material)

[0058] Take 0.5 g of industrially produced metatitanic acid, add it to a 40 ml hydrothermal kettle, add 3 mol / L NaOH solution to the kettle, heat it at 300°C for 1 day, wash the white precipitate with deionized water, and dry it. Nanotubes of sodium titanate hydrate were obtained. Its molecular formula can be expressed as: Na x h 2-x Ti 2 o 5 ·H 2 O(x=0.1-1)

[0059] Repeat the above operation steps, increase the concentration of lye to 15 mol / liter, heat at 300° C. for 3 hours, and obtain nanotubes of hydrated sodium titanate.

[0060] Repeat the above operation steps, increase the concentration of lye to 7 mol / liter, heat at 160°C for 3 days, and obtain nanotubes of hydrated sodium titanate.

[0061] Repeat the above operation steps, increase the concentration of lye to 15 mol / L, heat at 60°C for 8 days, and obtain nanotubes of hydrated sodium titanate....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com