Catalyst for producing ethanol and preparation method thereof

A catalyst and a technology for producing ethanol, which are applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of limited large-scale industrial application of catalyst costs, low space-time yield of ethanol, etc., and achieve inhibition of catalyst deactivation. , Small change in activity, the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Dissolve 0.75g of nickel nitrate and 0.36g of ferric nitrate in 50mL of deionized water, add 1g of silicon dioxide, and stir for 1h with the aid of ultrasonic waves. Weigh 0.20 g of potassium borohydride and dissolve it in 5 mL of deionized water, add it into the above mixture with stirring, slowly raise the temperature to 70 °C and continue stirring for 4 h, filter and wash. The obtained solid was dispersed in 10 mL of deionized water, 7.35 mL of 0.1 g / mL aluminum nitrate solution was slowly dropped into the above suspension, stirred and evaporated to dryness at 90 °C, and then calcined at 500 °C for 4 h. The catalyst pellets were sieved to obtain 40-60 mesh solids in 5%H 2 -95%N 2 Reduction in a mixed gas atmosphere for 4 hours, the reduction temperature is 600°C, and the obtained catalyst is 10% Al 2 o 3 15%Ni-5%Fe / SiO 2 .

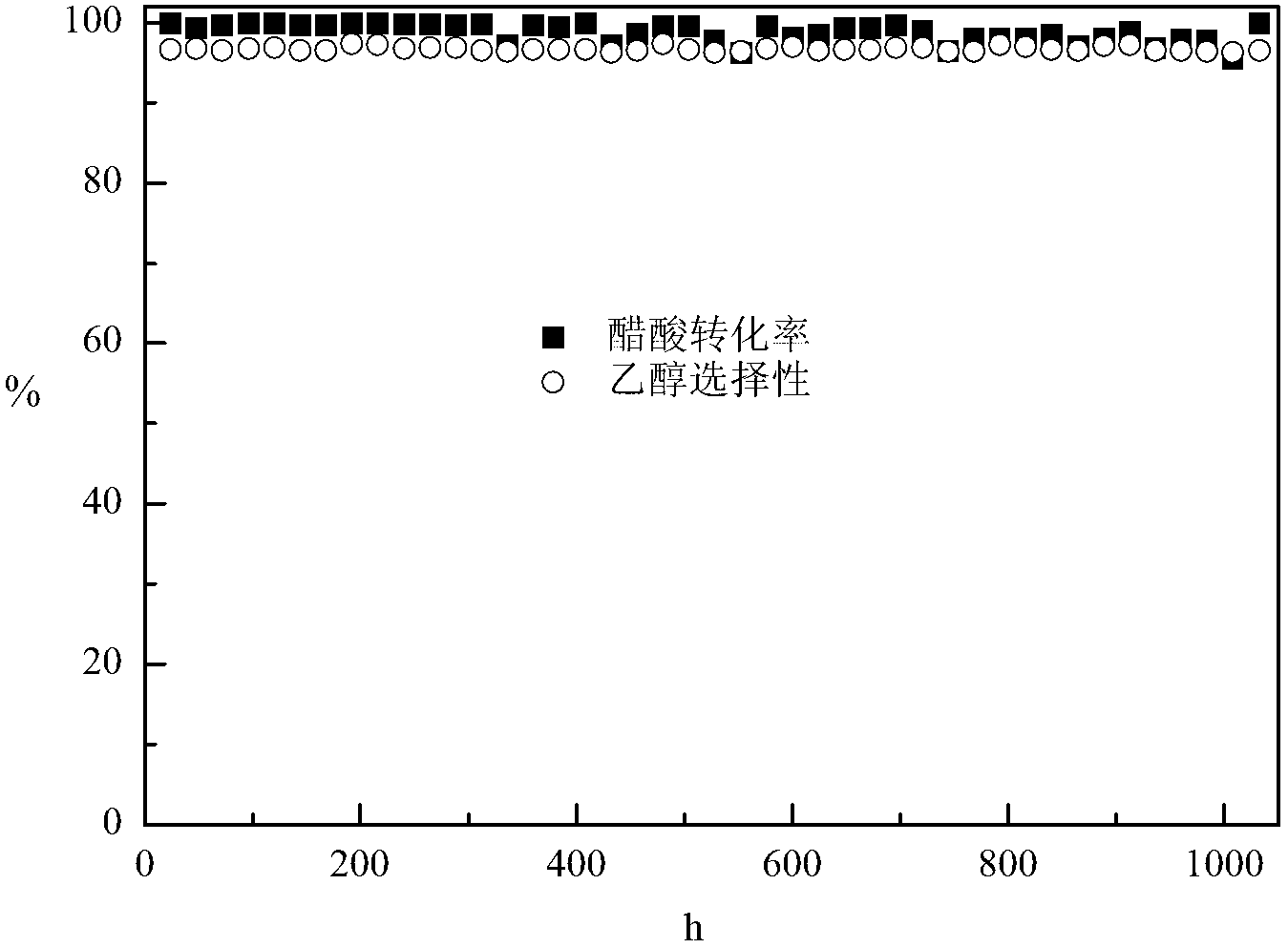

[0036] Using glacial acetic acid as the raw material, using a fixed-bed reaction system with a catalyst loading of 0.18g, the temperature w...

Embodiment 2

[0038] Keeping the reaction pressure, hydrogen-acid ratio, space velocity and other conditions in Example 1, the temperature was raised to 400°C at a rate of 5°C / min, and after 24 hours, the temperature was lowered back to 220°C, the conversion rate of acetic acid was 97.4%, and the selectivity of ethanol was 96.1% %, thermal stability coefficient 0.99.

Embodiment 3

[0040] Dissolve 0.50 g of nickel nitrate and 0.36 g of ferric nitrate in 30 mL of deionized water, add 1 g of silicon dioxide, and stir for 1 h with the aid of ultrasonic waves. Weigh 0.10g of sodium borohydride and dissolve it in 5mL of deionized water, add it into the above mixture under stirring, slowly raise the temperature to 70°C and continue stirring for 4h, filter and wash, and then roast at 500°C for 4h. The catalyst pellets were sieved to obtain 40-60 mesh solids in 5%H 2 -95%N 2 Reduction in a mixed gas atmosphere for 4 hours, the reduction temperature is 500°C, and the obtained catalyst is 10%Ni-5%Fe / SiO 2 .

[0041] Using glacial acetic acid as raw material, using a fixed-bed reaction system with a catalyst loading of 0.2g, raising the temperature to 220°C at a rate of 10°C / min under a hydrogen flow of 50mL / min, adjusting the hydrogen pressure to 2.0MPa, and controlling the hydrogen flow rate to 157mL / min. The liquid flow rate is 0.005mL / min, and the liquid hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com