Preparation method of high-reaction-activity hydroxyl acrylic resin

A hydroxy acrylic, highly reactive technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems such as the inability to further improve the comprehensive performance of the resin, the single molecular structure of the hydroxy acrylic resin, and the inability to realize the optimization of the combination of the hydroxy acrylic resin, etc. To achieve the effect of excellent compatibility, excellent comprehensive performance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

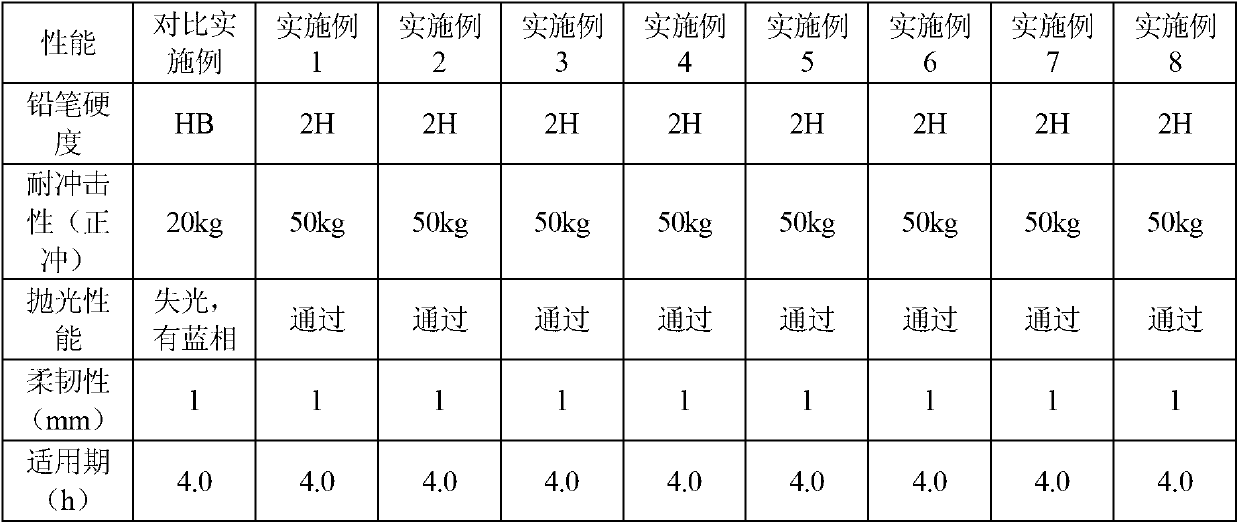

Examples

Embodiment 1

[0025] 1) First, under the protection of nitrogen, add 100 parts by weight of toluene into the reaction vessel, and raise the temperature to 130°C;

[0026] 2) Then, slowly drop a mixture of 50 parts by weight of methyl methacrylate, 5 parts of hydroxyethyl acrylate, 1 part of acrylic acid and 2 parts of azobisisobutyronitrile into the reaction vessel, and keep warm for 0.5 ~1h;

[0027] 3) Then, slowly drop a mixture of 10 parts of methyl acrylate, 15 parts of ethyl acrylate, 25 parts of propyl acrylate, 10 parts of hydroxyethyl acrylate, 3 parts of acrylic acid and 1 part of azobisisobutyronitrile into the reaction In the container, keep warm for 1~2h;

[0028] 4) Finally, the temperature of the material is lowered to below 70°C to obtain a hydroxyacrylic resin product.

Embodiment 2

[0030] 1) First, under the protection of helium, add 50 parts by weight of butyl acetate and 50 parts of xylene into the reaction vessel, and raise the temperature to 80°C;

[0031] 2) Then, 40 parts by weight of tert-butyl methacrylate, 20 parts of ethyl methacrylate, 10 parts of ethyl acrylate, 15 parts of hydroxypropyl acrylate, 1 part of tert-butyl peroxybenzoate and 3 Slowly drop the mixture of benzoyl peroxide into the reaction vessel and keep it warm for 0.5~1h;

[0032] 3) Then, 3 parts of ethyl methacrylate, 20 parts of 2-ethylhexyl acrylate, 20 parts of butyl acrylate, 5 parts of hydroxypropyl acrylate and 3 parts of initiator benzoyl peroxide The mixture was slowly added dropwise into the reaction vessel and kept warm for 1~2h;

[0033] 4) Finally, the temperature of the material is lowered to below 70°C to obtain a hydroxyacrylic resin product.

Embodiment 3

[0035] 1) First, under the protection of inert gas argon, add 100 parts by weight of methyl butyl ketone into the reaction vessel, and raise the temperature to 150°C;

[0036] 2) Then, the parts by weight are 30 parts of cyclohexyl methacrylate, 15 parts of phenyl methacrylate, 25 parts of trimethylcyclohexyl methacrylate, 2 parts of propyl acrylate, 8 parts of hydroxybutyl acrylate, Slowly add a mixture of 1 part of maleic acid, 2 parts of fumaric acid and 6 dicumyl peroxide dropwise into the reaction vessel, and keep it warm for 0.5~1h;

[0037]3) Then, add 1 part of tert-butyl methacrylate, 30 parts of soft monomer lauryl acrylate, 8 parts of hydroxybutyl acrylate, 1 part of maleic acid, 3 parts of fumaric acid and 5 parts A mixture of tert-butyl peroxybenzoate was slowly added dropwise into the reaction vessel, and kept warm for 1~2h;

[0038] 4) Finally, the temperature of the material is lowered to below 70°C to obtain a hydroxyacrylic resin product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com