Method for preparing colorized imitation metal wiredrawn film through UV transfer process

A technology of imitating metal and wire drawing film, which is applied in printing process, printing of special varieties of printed matter, and process for producing decorative surface effects, etc., can solve the problems of aging resistance of ink printing layer, failure of metal texture, cumbersome process, etc. , to achieve the effect of being suitable for large-scale production, stable test performance, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

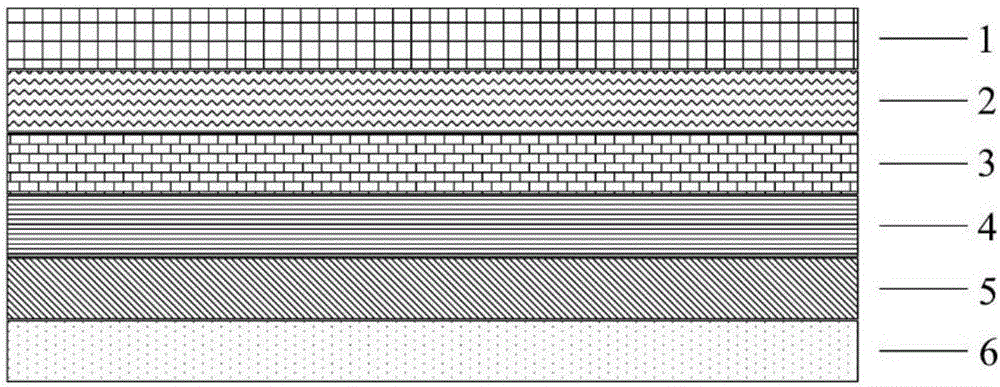

Image

Examples

Embodiment 1

[0026] Example 1: Preparation and performance testing of Tuhao gold imitation metal wire drawing film.

[0027] a) Prepare Tuhao golden UV glue:

[0028] Mix 2.3g of yellow color paste, 1.5g of red color paste and 0.35g of blue color paste (provided by Changzhou Zhongpu Chemical Co., Ltd.) for deploying Tuhao gold, and stir for 1 hour with a high-speed stirrer; then add the mixed color paste Add 100g of UV glue (purchased from Kaitong, South Korea, with good adhesion to SKC PET, and good adhesion to vacuum aluminum plating), and stir for 1 hour with a high-speed stirrer to obtain Tuhao golden UV glue.

[0029] b) Preparation of UV transfer printing tuhao golden brushed film:

[0030] A PET film (purchased from SKC, South Korea, with a thickness of 25 μm and a width of 800 mm) with its own pre-coating layer (thickness 0.1 μm) was selected, and a UV transfer molding machine with a wire drawing pattern was used (the hardness of the wire drawing layer was 1H, and the thickness 4...

Embodiment 2

[0034] Example 2: Preparation and performance test of rose gold imitation metal brushed film.

[0035] a) Prepare rose gold UV glue:

[0036] Mix 1.4g of yellow color paste and 1.4g of purple color paste (provided by Changzhou Zhongpu Chemical Co., Ltd.) for deploying rose gold, and stir with a high-speed stirrer for 1 hour; then add the mixed color paste to 100g of UV glue (purchased From Kaitong, South Korea, which has good adhesion to PET of SKC in Korea, and good adhesion to vacuum aluminum plating), stir with a high-speed stirrer for 1 hour to obtain rose gold UV glue.

[0037] b) Preparation of UV transfer rose gold brushed film:

[0038] A PET film (purchased from SKC, South Korea, with a thickness of 50 μm and a width of 800 mm) with a pre-coating layer (thickness of 2 μm) was selected, and a UV transfer molding machine with a wire drawing pattern was used (the hardness of the wire drawing layer was 1H, and the thickness was 100 mm). 20 μm) apply the rose gold UV glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com