High-elasticity waterborne polyurethane-acrylate composite resin, and preparation method and application thereof

A technology of water-based polyurethane and acrylate, applied in the direction of coating, etc., can solve the problem of less high-elastic resin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

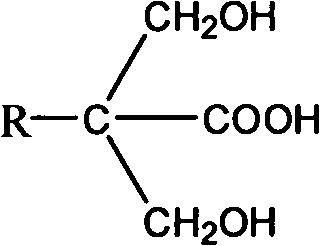

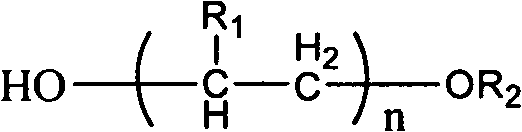

[0088] Add 45 parts of polyoxypropylene diol DL2000, 20 parts of WANNATE HMDI (Yantai Wanhua Polyurethane Co., Ltd., 4,4'-dicyclohexylmethane diisocyanate to the four-neck flask equipped with thermometer, reflux condenser and stirrer The content is 99.1%, the same below) and 0.02 parts of dibutyltin dilaurate, heat up to 85°C and keep warm for reaction, after the NCO content reaches 3.4%-3.6%, cool down to 50°C, add 1.1 parts of 1,4-butanediol , 3.9 parts of dimethylolpropionic acid and 21 parts of acetone, and react at a constant temperature at 80°C until the NCO content is 0.72%-0.82%.

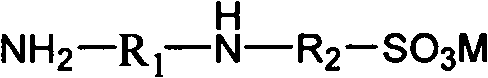

[0089] After cooling down to 50°C, add 35 parts of n-butyl methacrylate, 25 parts of isooctyl acrylate, and 3 parts of triethylamine, and keep stirring at 50°C for 10 minutes. Cool down to room temperature, slowly add 120 parts of deionized water to the above system at a shear rate of 1000r-min, and emulsify and disperse for 15 minutes. Add 1.6 parts of 50% hexamethylenediamine aqueous solu...

Embodiment 2

[0092] Add 50 parts of polytetrahydrofuran ether glycol PTMEG1000, 16 parts of HDI and 0.02 part of dibutyltin dilaurate into a four-neck flask equipped with a thermometer, reflux condenser and stirrer, raise the temperature to 85°C and keep it warm until the NCO content reaches 2.8%-3.1%, then lower the temperature to 50°C, add 3.9 parts of dimethylolpropionic acid and 22 parts of acetone, and react at a constant temperature at 80°C until the NCO content is 0.95%-1.2%.

[0093] After cooling down to 50°C, add 32 parts of n-butyl methacrylate, 18 parts of isooctyl acrylate, and 3 parts of triethylamine, and keep stirring at 50°C for 10 minutes. Cool down to room temperature, slowly add 108 parts of deionized water to the above system at a shear rate of 1000r-min, and emulsify and disperse for 15 minutes. Add 2.4 parts of hexamethylenediamine aqueous solution with a mass concentration of 50% to the dispersed emulsion, and stir for 10 minutes to obtain a water-based polyurethane...

Embodiment 3

[0097] Add 35 parts of polyoxypropylene diol DL2000, 10 parts of WANNATE HMDI, 5 parts of HDI and 0.02 parts of dibutyltin dilaurate into a four-necked flask equipped with a thermometer, reflux condenser and stirrer, raise the temperature to 85°C and keep it warm for reaction After the NCO content reaches 4.2%-4.6%, cool down to 50°C, add 3 parts of dimethylolpropionic acid and 16 parts of acetone, and react at a constant temperature at 80°C until the NCO content is 0.8%-1.1%.

[0098] After cooling down to 50°C, add 27 parts of n-butyl methacrylate, 13 parts of isooctyl acrylate, and 2.2 parts of triethylamine, and keep stirring at 50°C for 10 minutes. Cool down to room temperature, slowly add 86 parts of deionized water to the above system at a shear rate of 1000r-min, and emulsify and disperse for 15 minutes. Add 1.6 parts of hexamethylenediamine aqueous solution with a mass concentration of 50% to the dispersed emulsion, and stir for 10 minutes to obtain a water-based poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com