Covering device for aluminum tube installing hole of automobile roof rack

A luggage rack and mounting hole technology, applied in vehicle parts, transportation and packaging, additional accessories, etc., can solve the problems that the car cannot accommodate too many accompanying objects, cannot accommodate accompanying objects, and the appearance is not beautiful, so as to ensure the appearance of beautiful appearance. , the structure is simple, the effect of small color difference change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

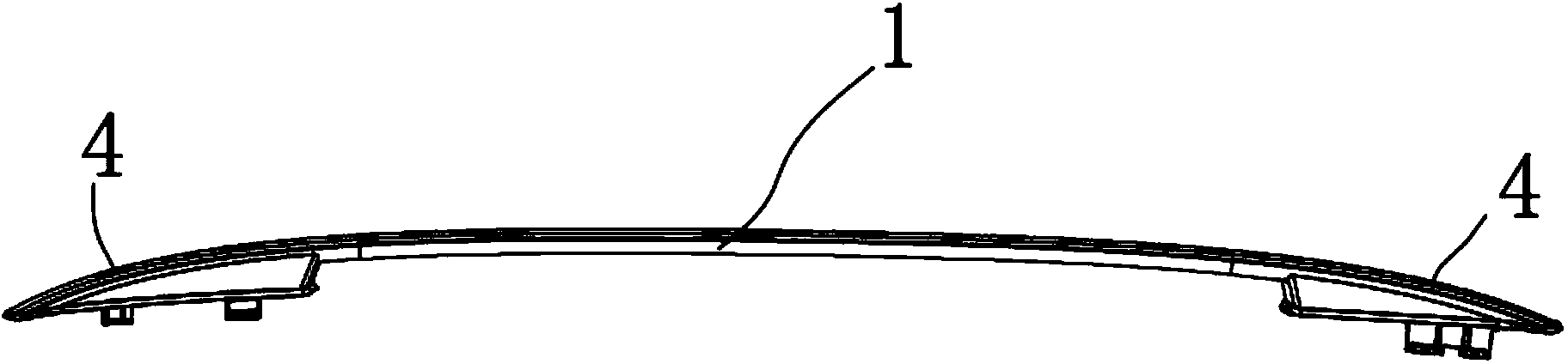

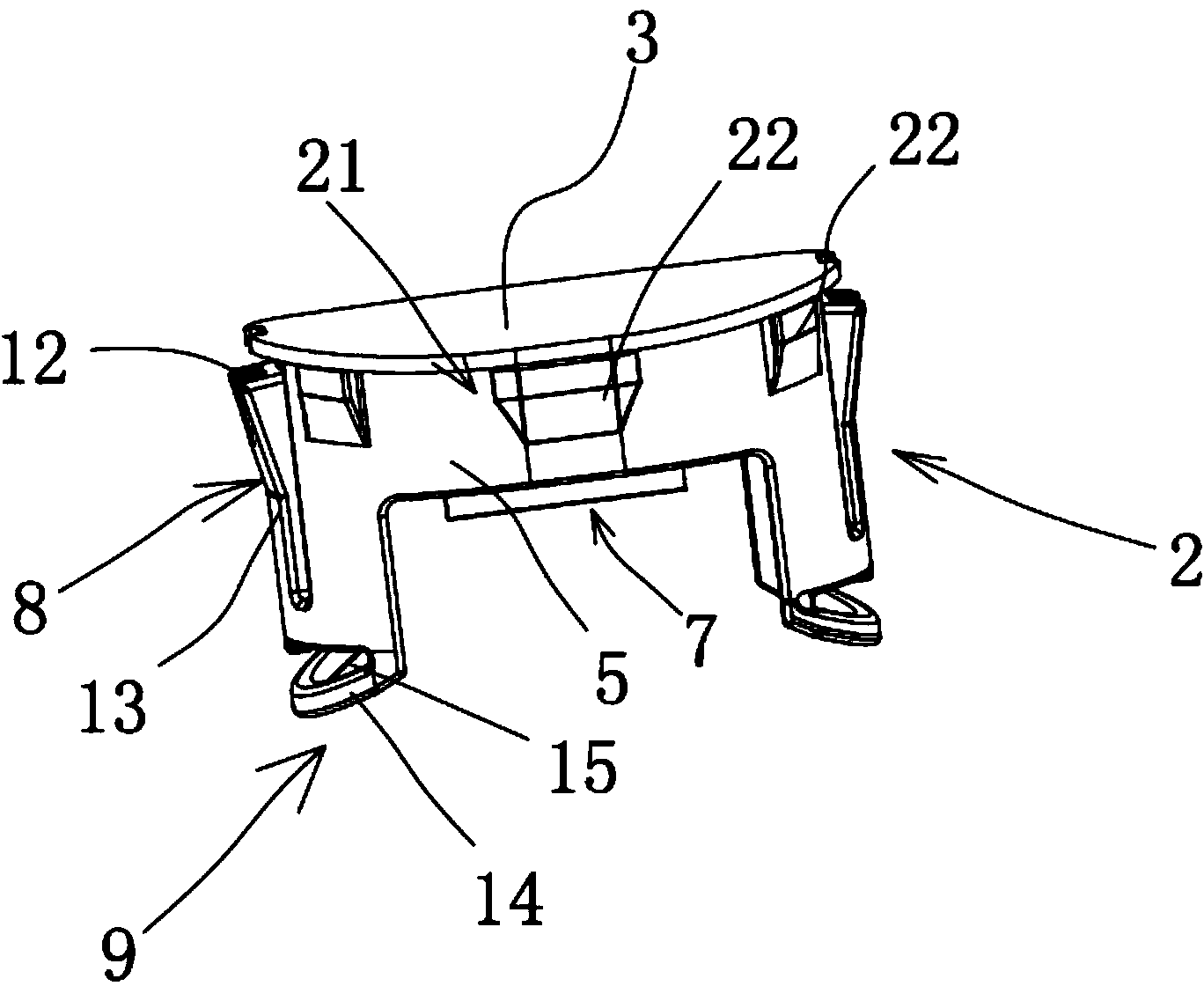

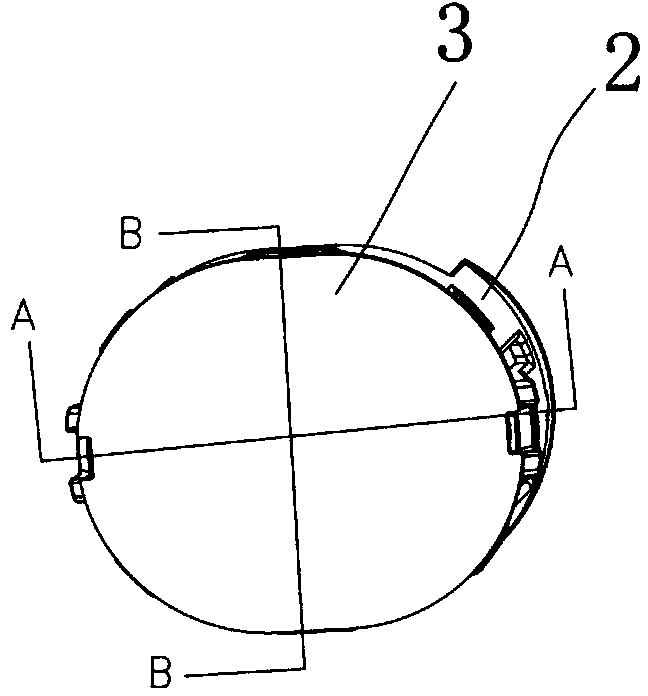

[0026] In the figure, luggage rack aluminum tube 1; plastic support 2; metal cover 3; installation hole 4; main body 5; Tube upper inner wall 10; aluminum tube lower inner wall 11; abutting head 12; elastic support part 13; ; Undercut head 20; edge positioning portion 21; positioning boss 22; elastic mouth 23.

[0027] like figure 1 , figure 2 as well as image 3 As shown, the cover device for the installation hole of the aluminum tube of the roof rack of the automobile is arranged in the installation hole 4 of the aluminum tube 1 of the luggage rack. The same material and the same anodizing process as the aluminum tube body are used, so that the color difference change at the installation hole 4 after covering is sma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com