A kind of pottery painted cultural relic reinforcement coating and preparation method thereof

A technology for strengthening paint and painting, applied in the direction of coating, etc., can solve the problems such as damage to the original appearance of pottery painted cultural relics, flaky powder of pottery body, cracking of painted layers, etc., and achieve outstanding anti-ultraviolet aging performance, strong adhesion, and reinforcement. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

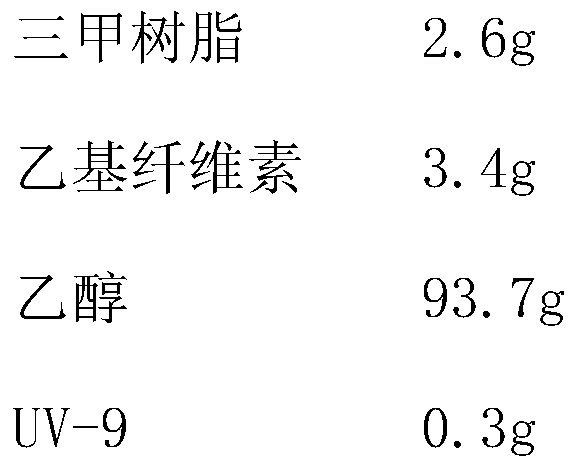

[0016] Taking the preparation of 100g pottery painted cultural relic reinforcement paint as an example, the components used and their mass composition are as follows:

[0017]

[0018] According to the dosage of the above-mentioned components, first dissolve ethyl cellulose completely in ethanol, then add trimethyl resin and UV-9, stir until completely dissolved, and then fill it to complete the preparation of the finished product of reinforced coating for ceramic painted cultural relics .

Embodiment 2

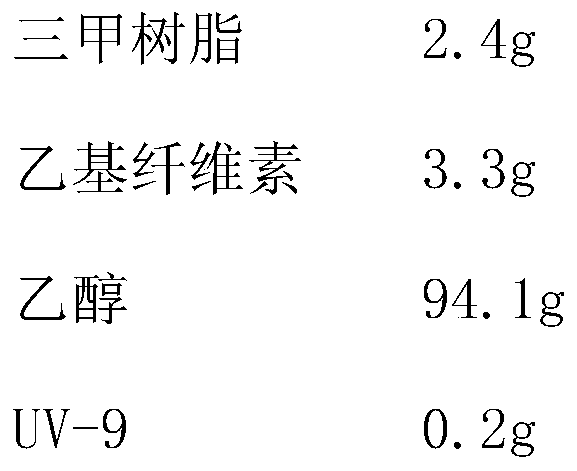

[0020] Taking the preparation of 100g pottery painted cultural relic reinforcement paint as an example, the components used and their mass composition are as follows:

[0021]

[0022] Its preparation method is identical with embodiment 1.

Embodiment 3

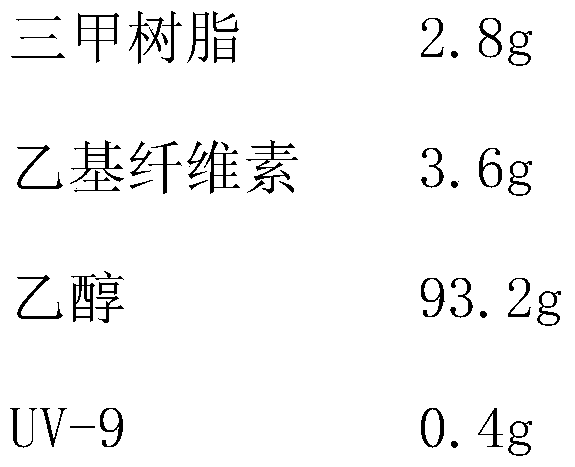

[0024] Taking the preparation of 100g pottery painted cultural relic reinforcement paint as an example, the components used and their mass composition are as follows:

[0025]

[0026] Its preparation method is identical with embodiment 1.

[0027] Use the X-RiteVS-450 spectrophotometer to test the color difference before and after three different ceramic simulated samples, and evaluate according to the American Society for Testing and Materials standard ASTM D1729-89 "Visual Evaluation of Color Difference of Opaque Materials". The results are shown in Table 1.

[0028] Table 1:

[0029]

[0030] It can be seen from Table 1 that the color difference before and after the ceramic simulation sample treated by the coating of the present invention is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com