Method for preparing banana beer and beer prepared by method

A banana and beer technology, applied in the direction of beer brewing, etc., can solve the problems of banana browning and precipitation, achieve sufficient heating, clear and thorough products, and solve the effects of wine turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

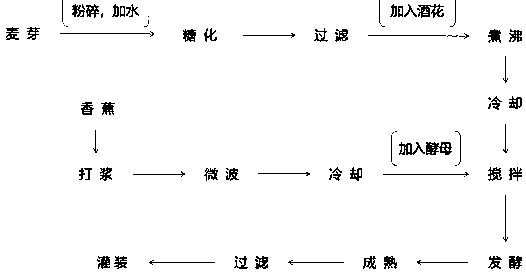

[0065] The preparation method of banana beer according to the present invention may comprise:

[0066] (1) Preparation of wort

[0067] Weigh and pulverize malt, add pure water to make malt crude juice, saccharify malt crude juice, filter, take the supernatant clear juice to obtain malt clear juice; add malt clear juice to hops and mix evenly, boil, and cool to fermentation temperature;

[0068] (2) Preparation of banana juice

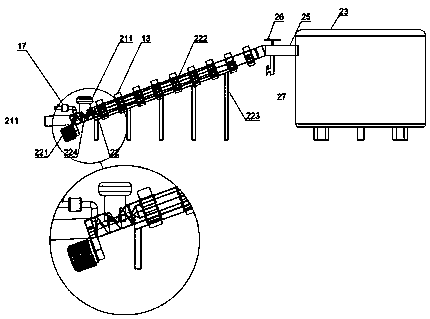

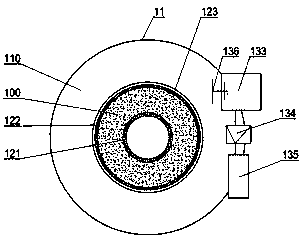

[0069] The screened bananas are removed from the head and tail and peeled to obtain banana pulp; the banana pulp is subjected to rough beating to obtain banana coarse pulp; the banana coarse pulp is transferred to a nitrogen positive pressure sealed pipeline microwave processing device through a closed pipeline for microwave extinguishing. Enzyme treatment, wherein the banana coarse pulp is heated by microwave while stirring and transporting with a spiral agitator in a microwave treatment device to obtain the banana coarse pulp treated by microwave en...

Embodiment 1

[0092] (1) Activation and expansion of beer yeast

[0093] After activating and culturing the brewer's yeast strains for 1-2 days, inoculate them into the Erlenmeyer flask on a slant, and cultivate them with shaking at 30°C for 2-3 days to obtain seed liquid; inoculate the seed liquid into the fermenter for expansion cultivation, 28-32 Cultivate for 2-4 days at a temperature of 5.3-5.7 at a pH of 5.3 to obtain bacterial cells.

[0094] (2) Preparation of wort

[0095] Weigh and pulverize the malt, add 10 times pure water to make malt crude juice, mash the malt crude juice, filter, take the supernatant clear juice to obtain malt clear juice; add 0.14% hops to the malt clear juice, mix well, boil, and cool to fermentation temperature ;

[0096] Preparation of Banana Juice

[0097] The screened bananas are removed from the head and tail and peeled to obtain banana pulp; the banana pulp is subjected to rough beating to obtain banana coarse pulp; the banana coarse pulp is transf...

Embodiment 2

[0103] (1) Activation and expansion of beer yeast

[0104] After activating and culturing the brewer's yeast strains for 1-2 days, inoculate them into the Erlenmeyer flask on a slant, and cultivate them with shaking at 30°C for 2-3 days to obtain seed liquid; inoculate the seed liquid into the fermenter for expansion cultivation, 28-32 Cultivate for 2-4 days at a temperature of 5.3-5.7 at a pH of 5.3 to obtain bacterial cells.

[0105] (2) Preparation of wort

[0106] Weigh and pulverize malt, add 10 times pure water to make malt crude juice, saccharify malt crude juice, filter, take the supernatant clear juice to obtain malt clear juice; add 0.1% hops to the malt clear juice, mix well, boil, and cool to fermentation temperature ;

[0107] Preparation of Banana Juice

[0108] The screened bananas are removed from the head and tail and peeled to obtain banana pulp; the banana pulp is subjected to rough beating to obtain banana coarse pulp; the banana coarse pulp is transferr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brown coloration index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com