Bonding promoter for addition type silicone rubber as well as preparation method and application of bonding promoter

A technology of adhesion promoter and silicone rubber, which is applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of poor adhesive performance of addition-type silicone rubber, and achieve improved transparency and compatibility , Improve the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

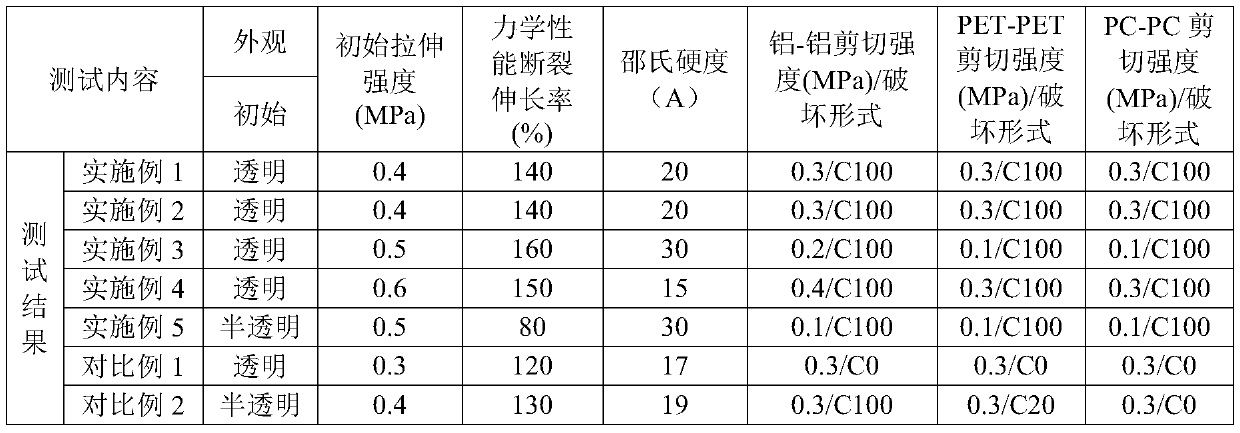

Examples

preparation example Construction

[0018] Due to the poor bonding effect of the existing adhesion promoters for addition-type rubber, in order to improve the adhesion performance, in a typical implementation of the application, a preparation of an adhesion promoter for addition-type silicone rubber is provided. The preparation method comprises: reacting tetramethylcyclotetrasiloxane with the first mixture to obtain the first reaction product; mixing the first reaction product with 1-ethynyl-1-cyclohexanol to obtain the second Mixture; the second mixture is reacted with allyl glycidyl ether to obtain an adhesion promoter for addition-type silicone rubber; wherein, the first mixture includes bis(trimethoxysilylmethyl)ethylene and a platinum content of 1500- 4500ppm platinum complex.

[0019] In the above preparation method, by using bis(trimethoxysilylmethyl)ethylene as a raw material, compared with acrylate, etc., the compatibility of the prepared adhesion promoter and the system can be improved, and the transpa...

Embodiment 1

[0038] (1) Synthesis of adhesion promoter

[0039] Measure 100 g (0.4.mol) of bis(trimethoxysilylmethyl)ethylene into a three-necked flask, add 0.3 g of divinyltetramethyldisiloxane complex of chloroplatinic acid with a platinum content of 2000 ppm, Mix well under the protection of nitrogen, and heat at 60°C for 30 minutes for later use. Measure 140g (0.4mol) of tetramethylcyclotetrasiloxane into a four-necked flask with a thermometer and a condensing reflux tube, stir and heat to 60°C under the protection of nitrogen, and start dropwise preheating with a constant pressure dropping funnel A good mixture of bis(trimethoxysilylmethyl)ethylene and isopropanol solution of chloroplatinic acid was added dropwise at 60°C for 1 hour. After the dropwise addition was completed, the temperature was raised to 80° C. to continue the reaction for 2 h and then lowered to room temperature. Add 0.05g of 1-ethynyl-1-cyclohexanol, stir evenly, and start to add 38.5g (0.3mol) allyl glycidyl eth...

Embodiment 2

[0043] (1) Synthesis of adhesion promoter

[0044] Measure 248.5g (1mol) of bis(trimethoxysilylmethyl)ethylene into a three-necked flask, add 0.5g of divinyltetramethyldisiloxane complex of chloroplatinic acid with a platinum content of 1500ppm, nitrogen Mix evenly under protection, heat at 55°C for 30 minutes and set aside. Measure 344.g (1mol) of tetramethylcyclotetrasiloxane into a four-necked flask equipped with a thermometer and a condensing reflux tube, stir and heat to 55°C under the protection of nitrogen, and start dropping the pre- The heated mixture of bis(trimethoxysilylmethyl)ethylene and isopropanol solution of chloroplatinic acid was added dropwise at 55°C for 1.5 hours. After the dropwise addition, the temperature was raised to 75° C. to continue the reaction for 4 h and then lowered to room temperature. Add 0.5g of 1-ethynyl-1-cyclohexanol, stir evenly, and start to add 114g (1mol) allyl glycidyl ether dropwise with a constant pressure dropping funnel, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com