Purification process and purification device for super-mature vinegar

A technology of purification process and purification device, which is applied in the field of vinegar production, and can solve problems such as excessive bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

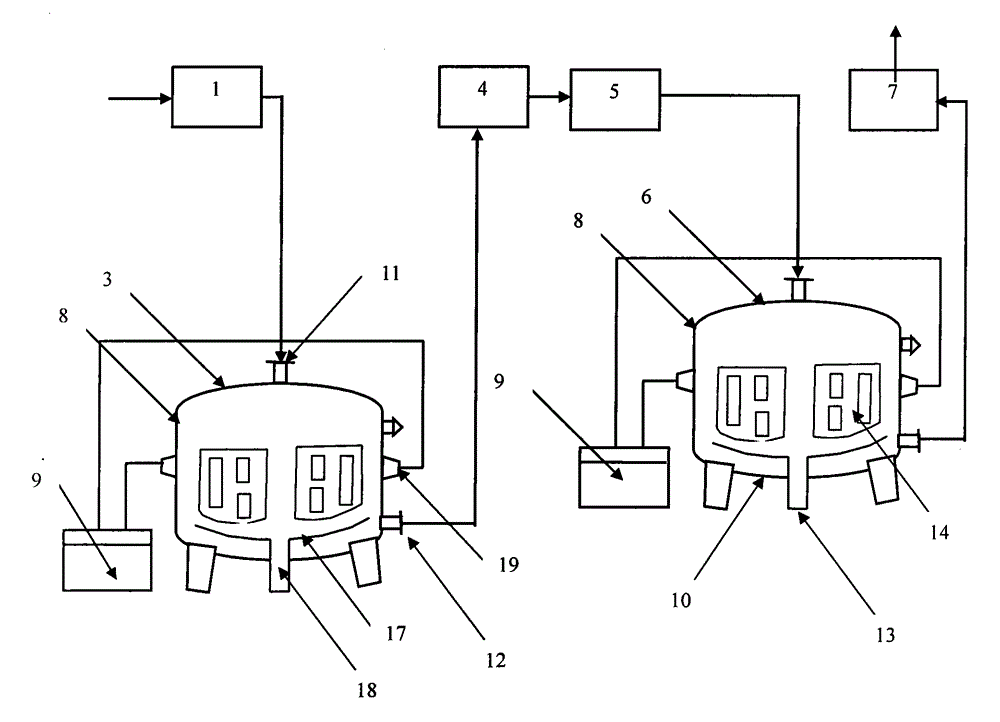

Method used

Image

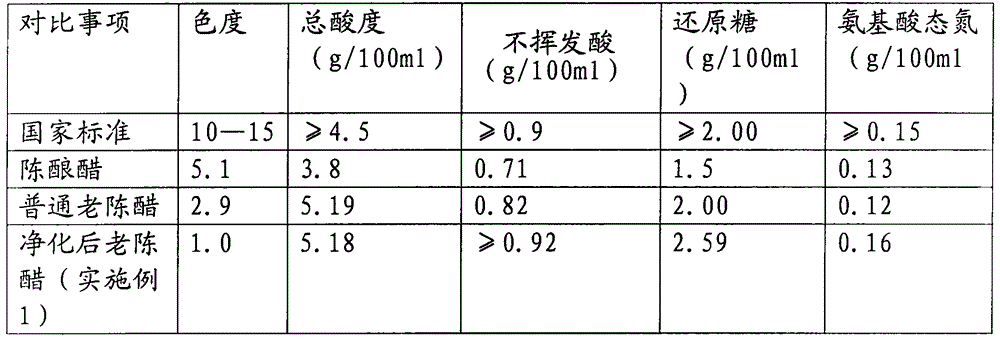

Examples

Embodiment 1

[0048] (1) Coarse filtration of aged vinegar;

[0049] (2) The vinegar solution after coarse filtration in step (1) is subjected to shaking and agglomeration treatment;

[0050] (3) Sterilize the vinegar solution after step (2) shaking and agglomerate, the temperature of the sterilization treatment is 80 degrees Celsius, and the treatment is 2 hours;

[0051] (4) Carry out a second aging treatment on the vinegar after sterilization, and let it stand for 15 days at room temperature;

[0052] (5) The vinegar solution treated in step (4) is subjected to secondary shaking and agglomeration treatment;

[0053] (6) Carry out the secondary sterilization treatment on the vinegar solution processed in step (5), the temperature during the sterilization treatment is 100 degrees Celsius, and the subsequent filling can be carried out after 2 hours of treatment;

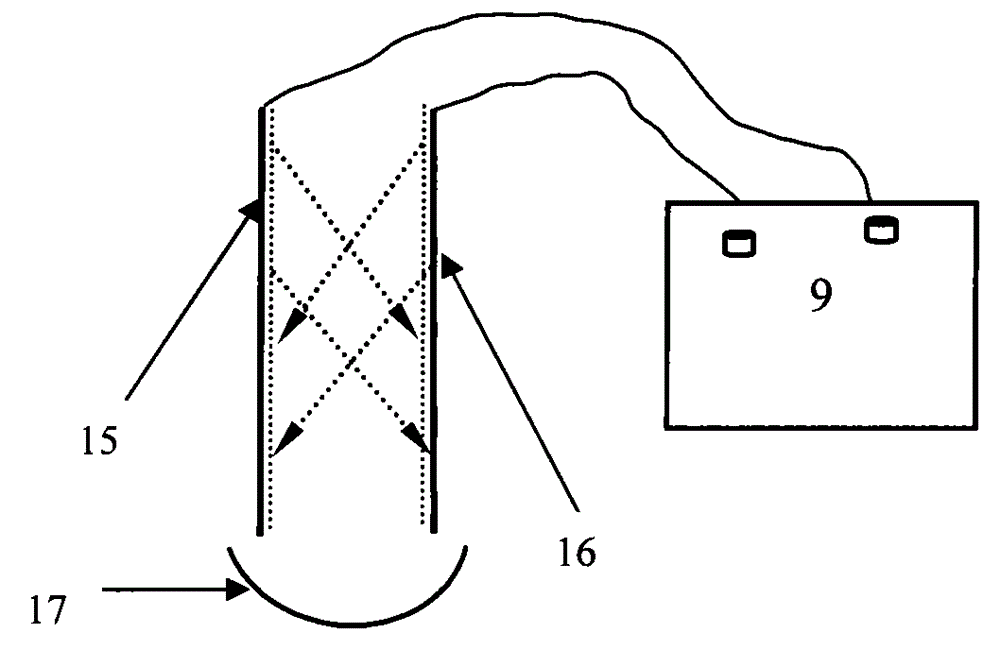

[0054] Wherein, the oscillation aggregation treatment and the secondary oscillation aggregation treatment are: using a voltage of 3000 volt...

Embodiment 2

[0056] (1) Coarse filtration of aged vinegar;

[0057] (2) The vinegar solution after coarse filtration in step (1) is subjected to shaking and agglomeration treatment;

[0058] (3) Sterilize the vinegar solution after step (2) shaking and agglomerate, the temperature during the sterilization treatment is 90 degrees Celsius, and the treatment is for 1 hour;

[0059] (4) Carry out secondary aging treatment to the sterilized vinegar and let it stand for 18 days at room temperature;

[0060] (5) The vinegar solution treated in step (4) is subjected to secondary shaking and agglomeration treatment;

[0061] (6) Carry out a secondary sterilization treatment on the vinegar solution treated in step (5), the temperature during the sterilization treatment is 100 degrees Celsius, and the subsequent filling can be carried out after 1 hour of treatment;

[0062] Wherein, the oscillation aggregation treatment and the secondary oscillation aggregation treatment are: using a voltage of 3800 volts to di...

Embodiment 3

[0064] (1) Coarse filtration of aged vinegar;

[0065] (2) The vinegar solution after coarse filtration in step (1) is subjected to shaking and agglomeration treatment;

[0066] (3) Sterilize the vinegar solution after step (2) shaking and agglomerate, the temperature during the sterilization is 100 degrees Celsius, and the treatment is 2 hours;

[0067] (4) Carry out a second aging treatment on the vinegar after sterilization, and let it stand for 15 days at room temperature;

[0068] (5) The vinegar solution treated in step (4) is subjected to secondary shaking and agglomeration treatment;

[0069] (6) Carry out the secondary sterilization treatment on the vinegar solution processed in step (5), the temperature during the sterilization treatment is 100 degrees Celsius, and the subsequent filling can be carried out after 2 hours of treatment;

[0070] Wherein, the oscillation aggregation treatment and the secondary oscillation aggregation treatment are: using a voltage of 3000 volts to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com