Patents

Literature

38results about How to "Reduce edge thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prescribing and/or dispensing ophthalmic lenses

ActiveUS20050122472A1Reduce sagittal addition powerReduce edge thicknessSpectales/gogglesEye surgeryMedical prescriptionProgressive addition lenses

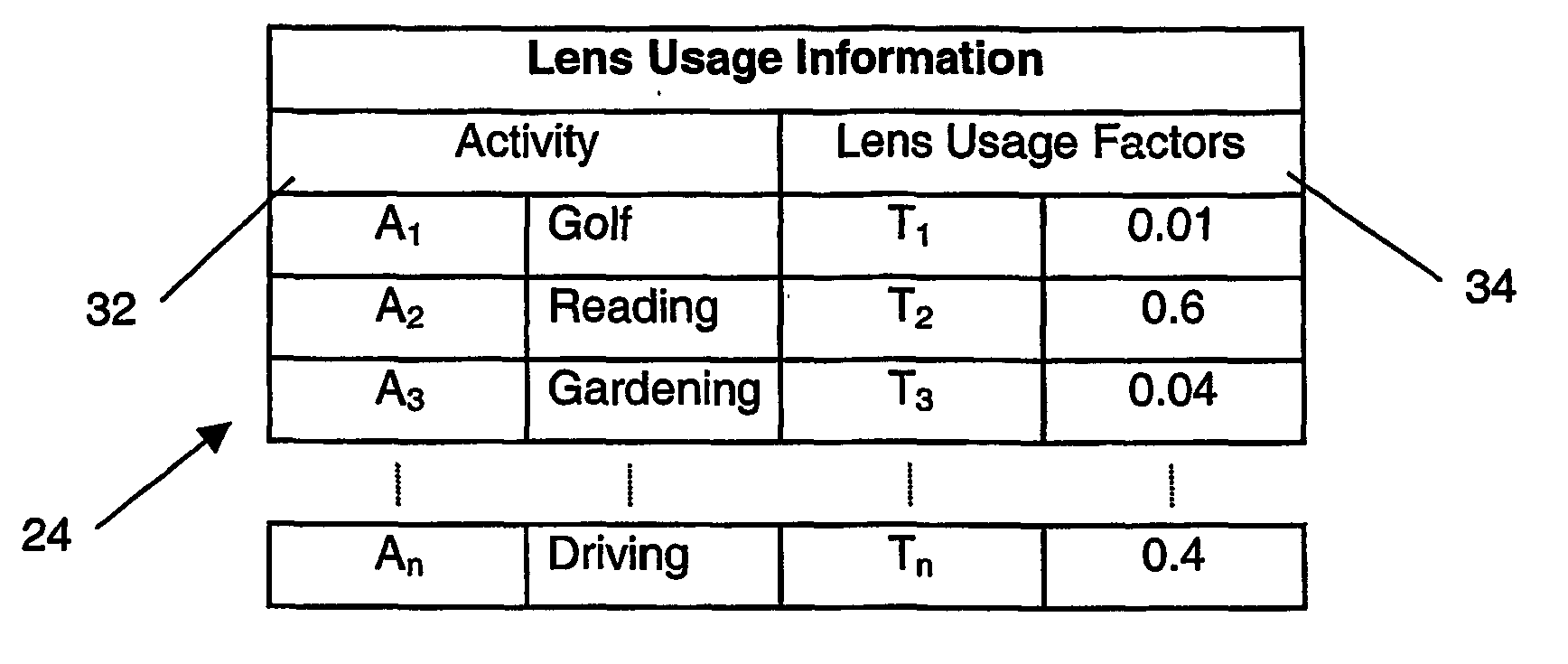

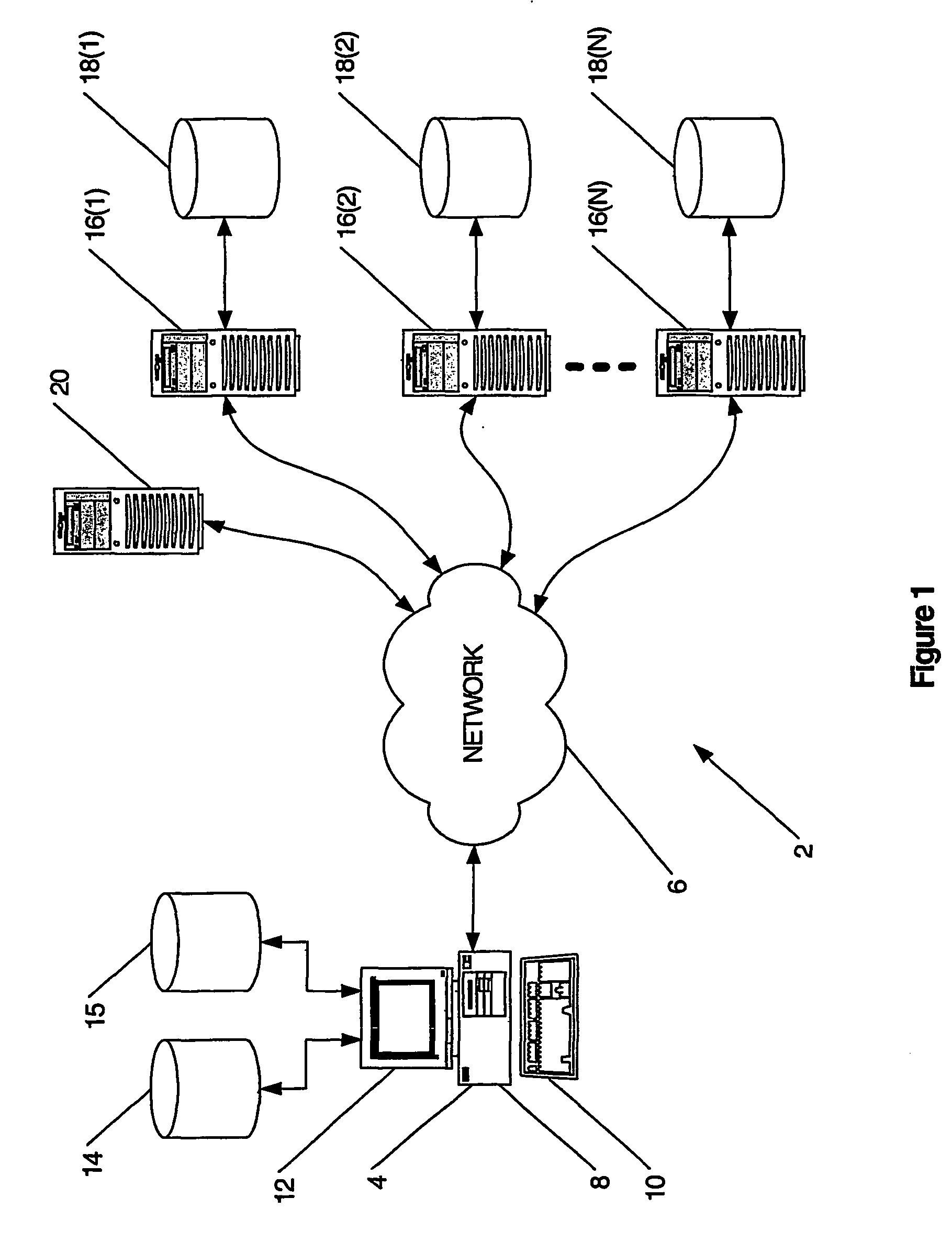

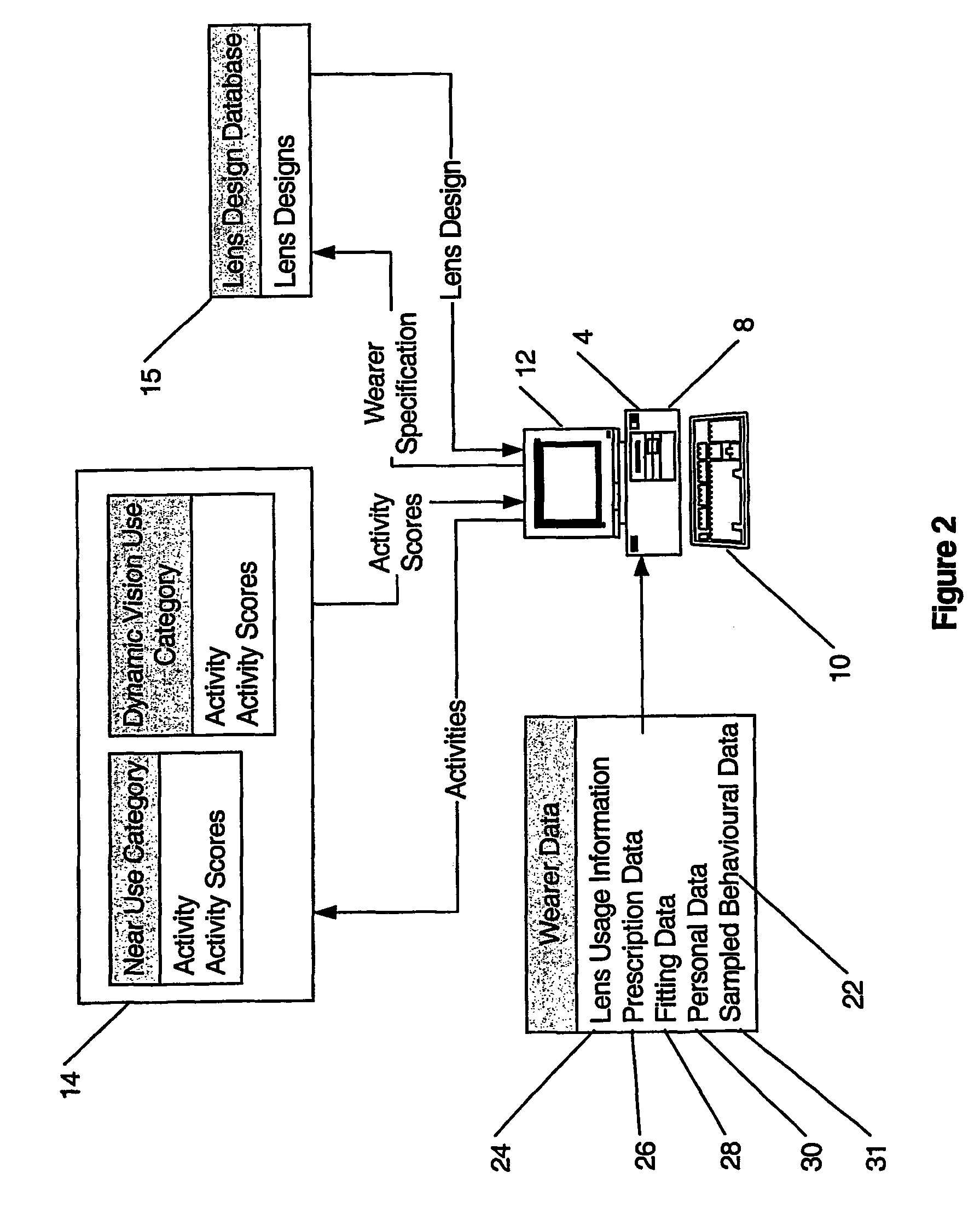

The present invention involves the prescribing and / or dispensing ophthalmic lenses, such as progressive addition lenses, for a wearer. In one form of the invention lens usage information is obtained from a wearer and entered into a programmed computer. The programmed computer processes the lens usage information to provide a separate weighted lifestyle score for each of one or more respective lifestyle score categories, such that each weighted lifestyle score is a function of a predetermined relationship between the respective lifestyle score category and at least ophthalmic lens design feature. The programmed computer then selects or designs an ophthalmic lens design using one or more of the weighted lifestyle scores such that the selected or designed ophthalmic lens has at least one lens design feature which has been customised using one or more of the weighted lifestyle scores.

Owner:CARL ZEISS VISION AUSTRALIA HO

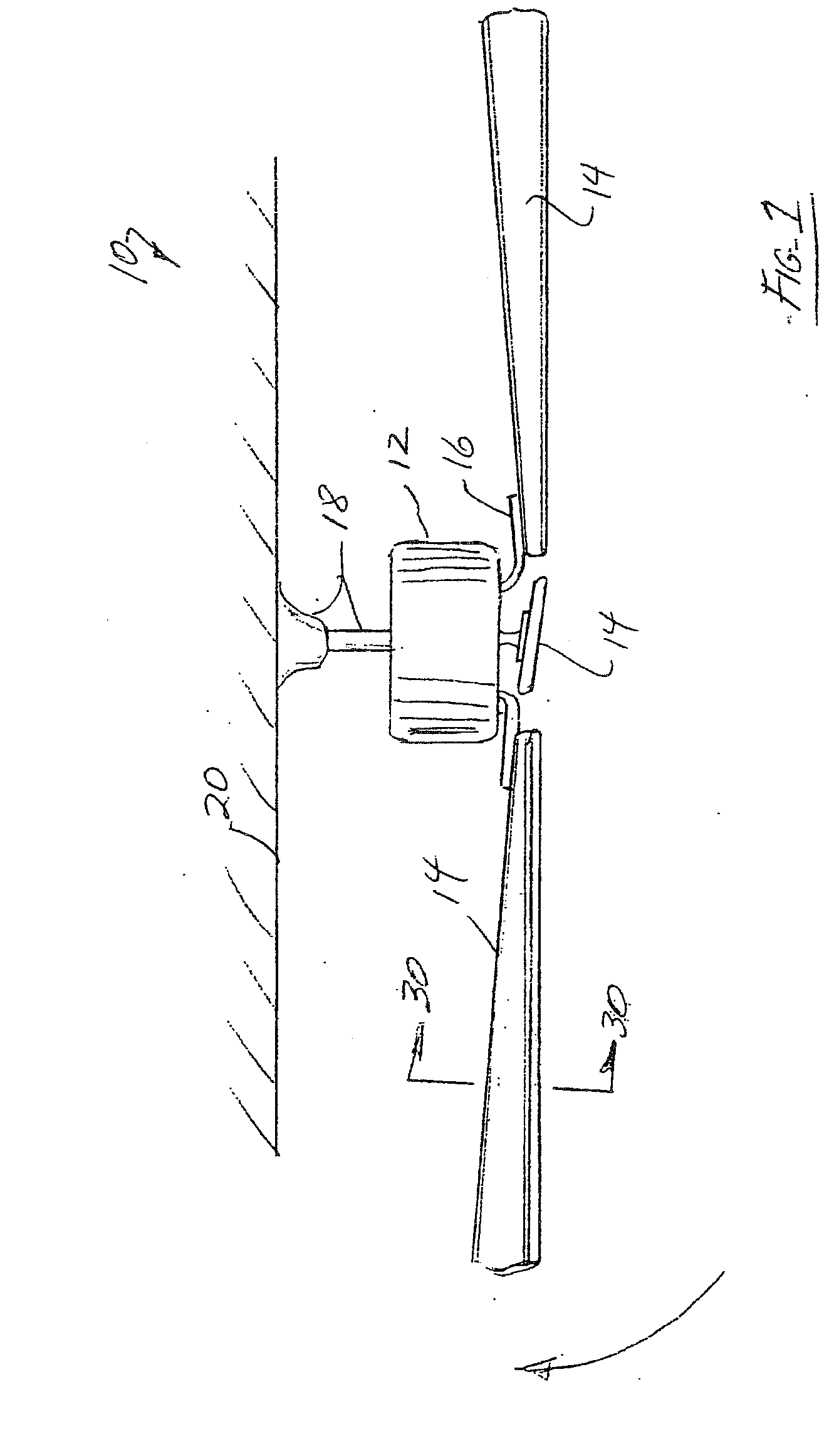

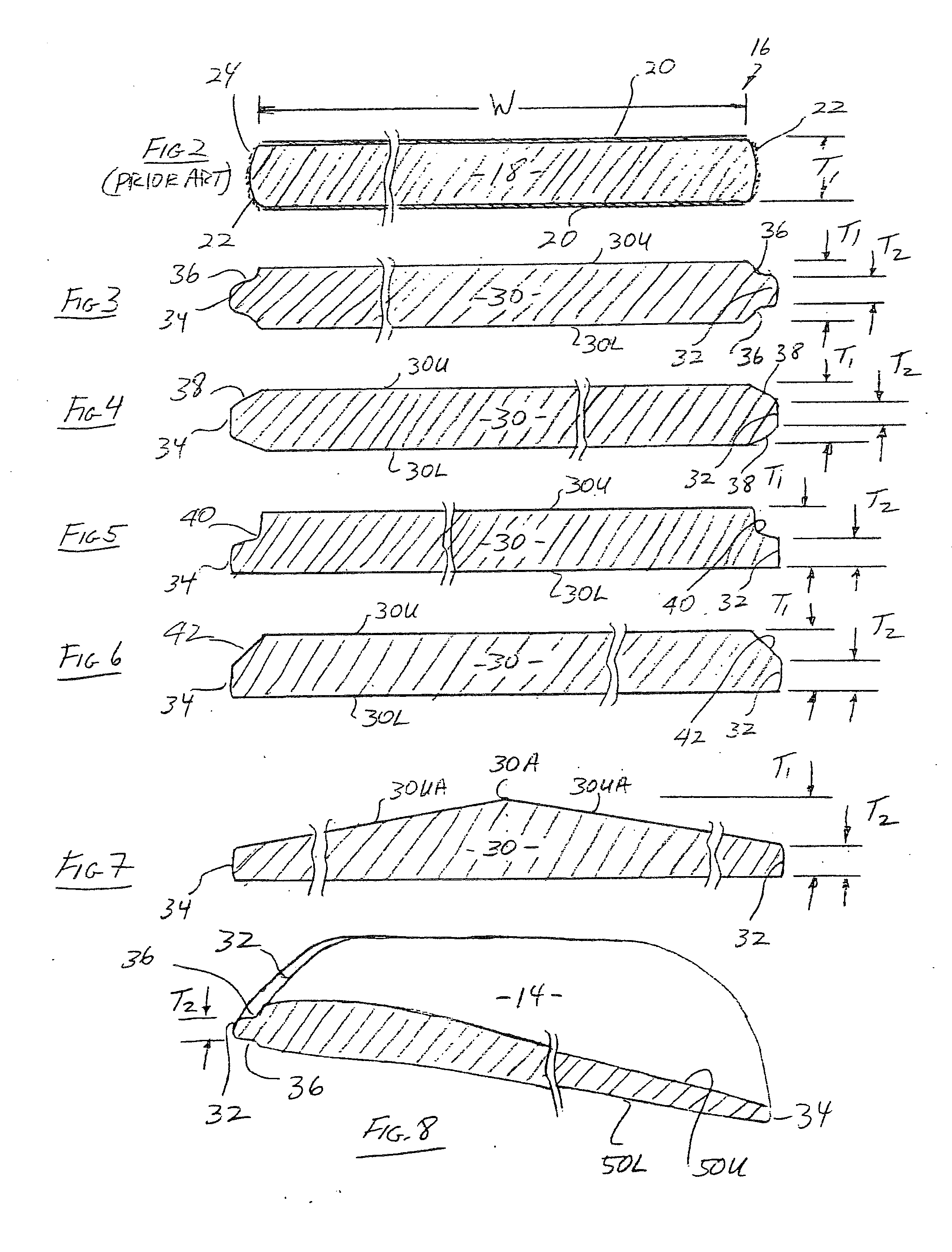

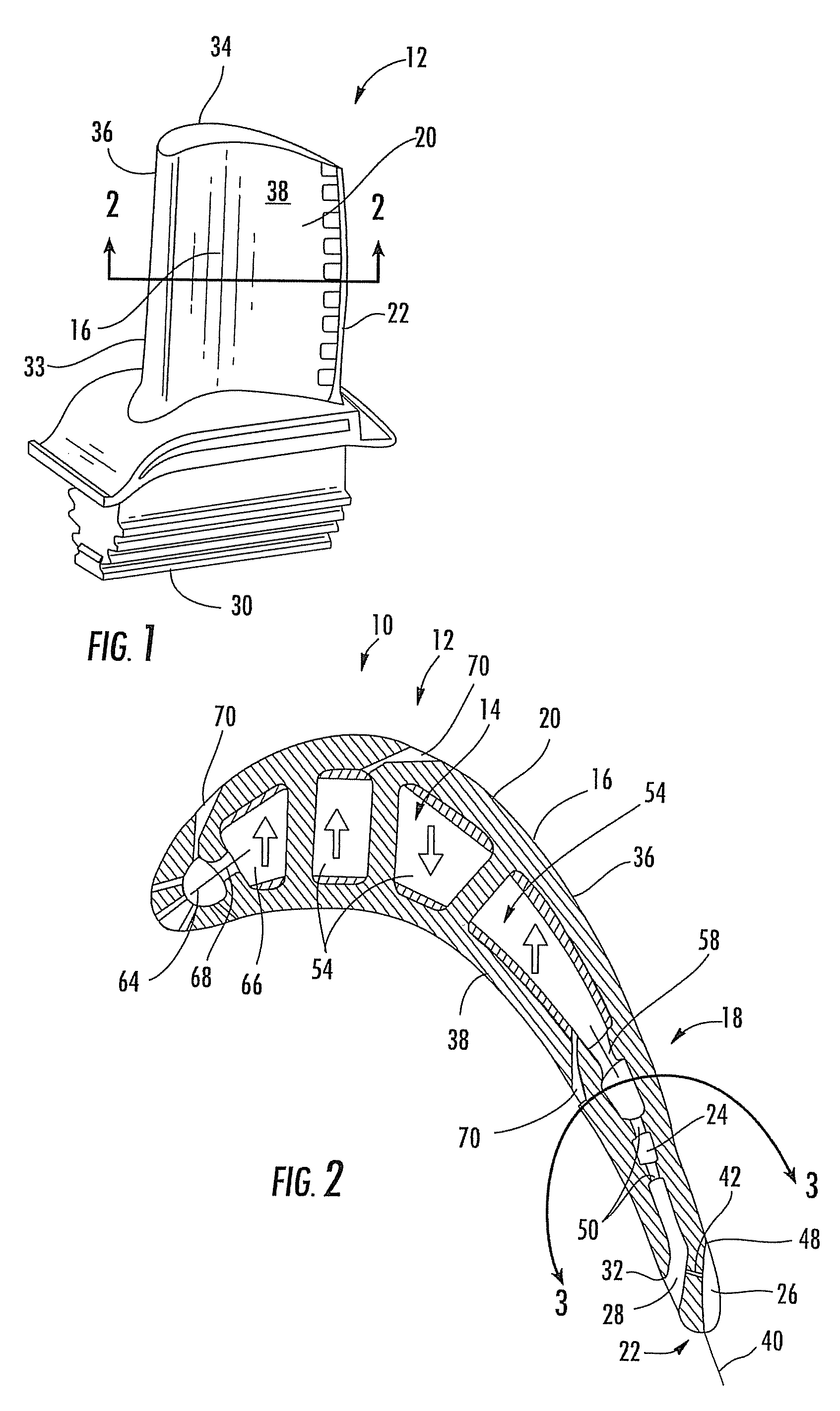

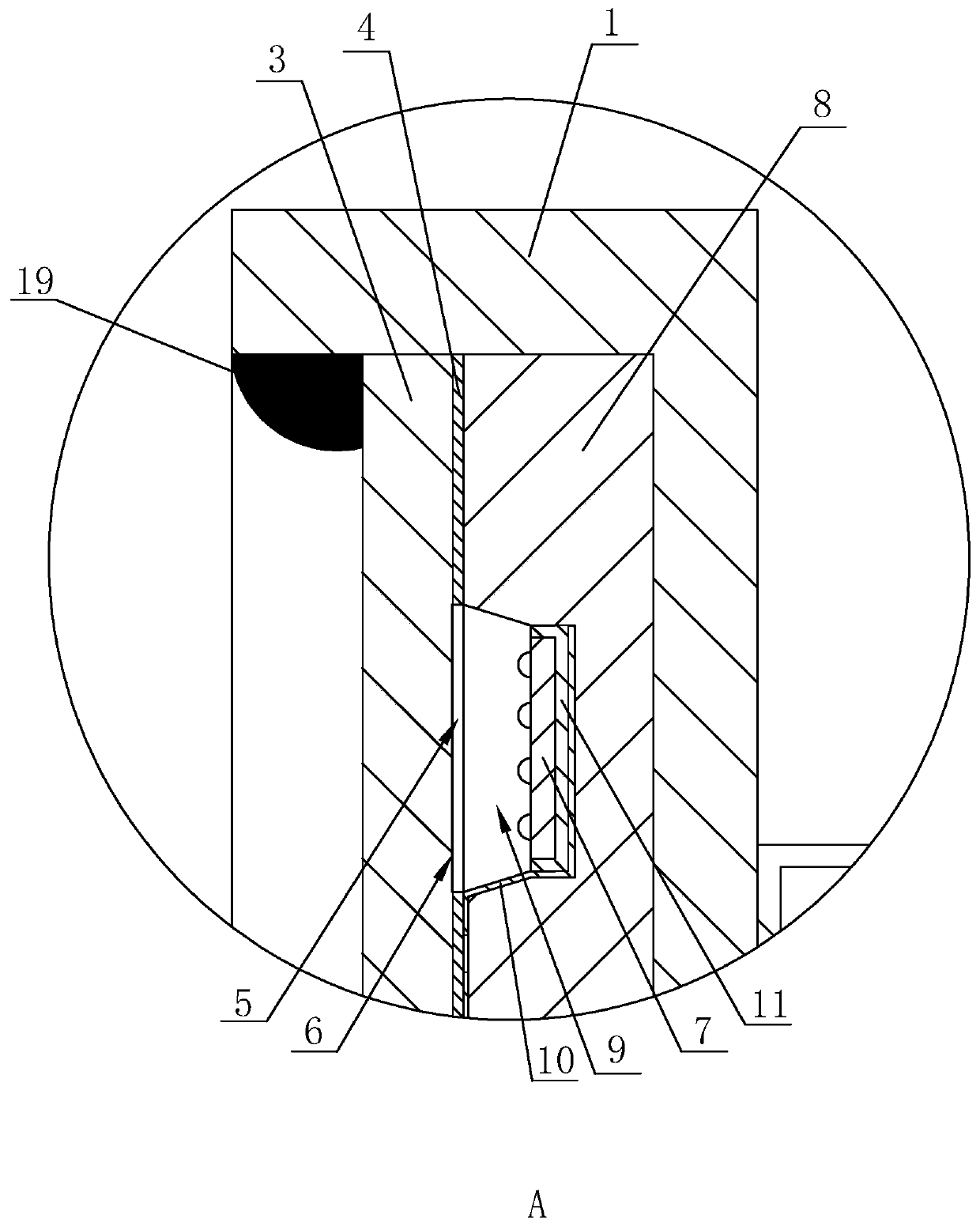

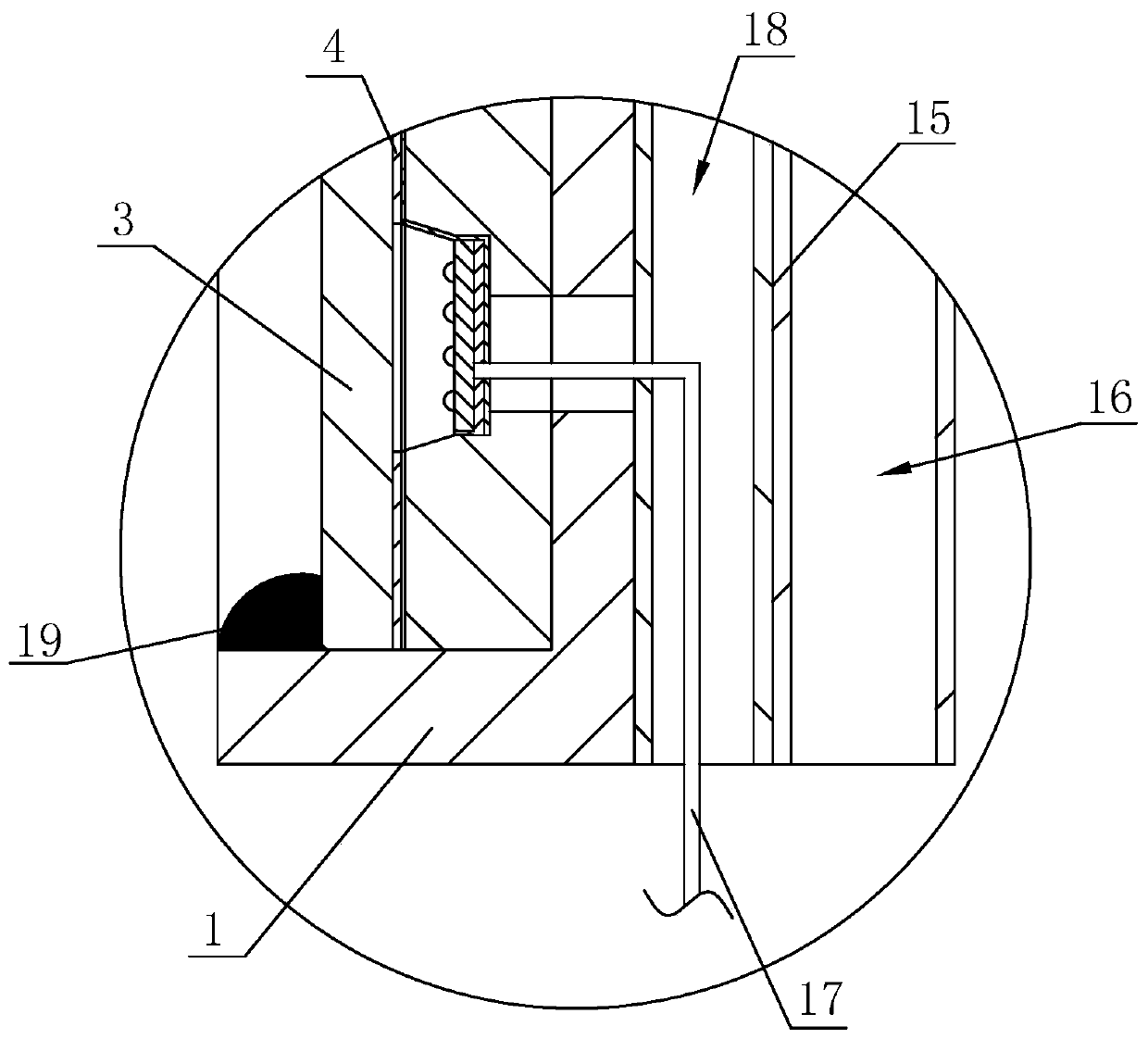

Ceiling Fan With High Efficiency Ceiling Fan Blades

InactiveUS20090263254A1High efficiencyReduce thicknessPump componentsMetal-working apparatusCeiling fanLeading-edge slats

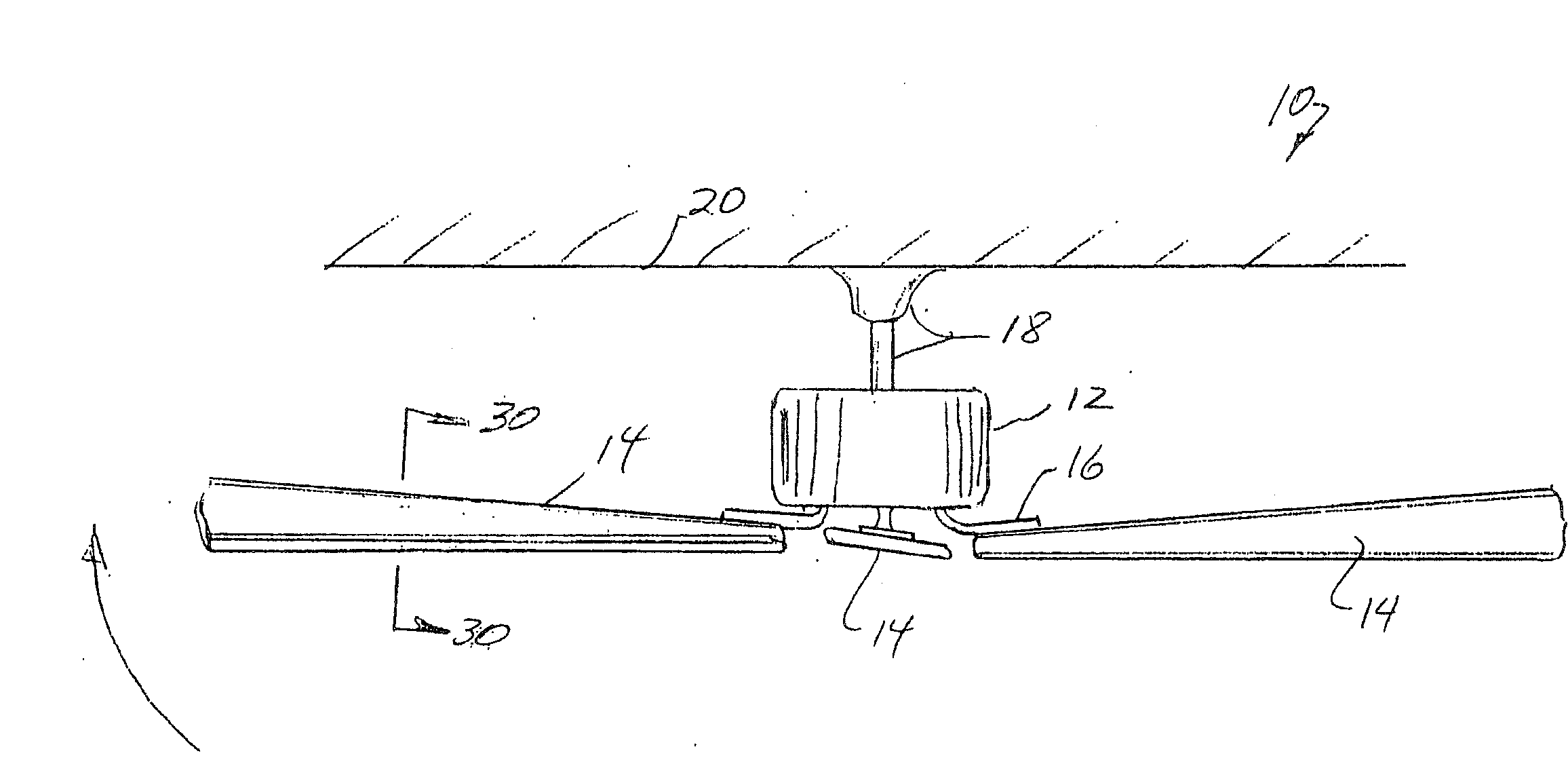

A ceiling fan including a motor having a rotatable rotor, a plurality of ceiling fans blades having a thickness, the blades connected to the rotor to rotate therewith and each of the ceiling fan blades comprising a thin edge along its leading edge that is thinner than the thickness of the ceiling fan blade to present less resistance and produce less turbulence and achieve high efficiencies.

Owner:KING OF FANS

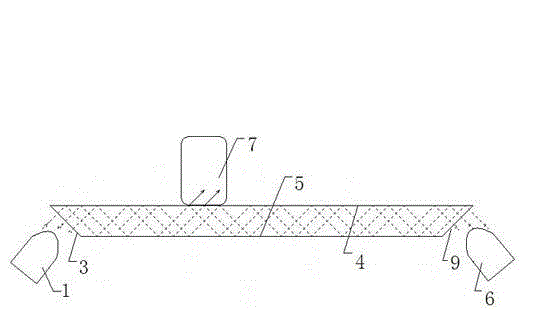

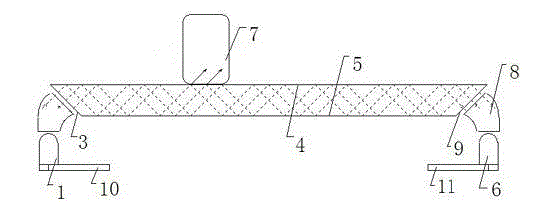

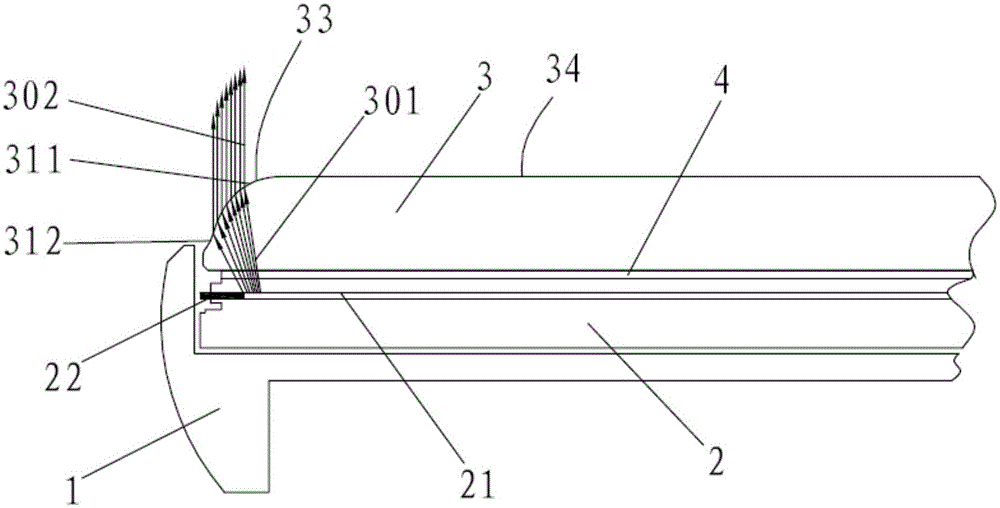

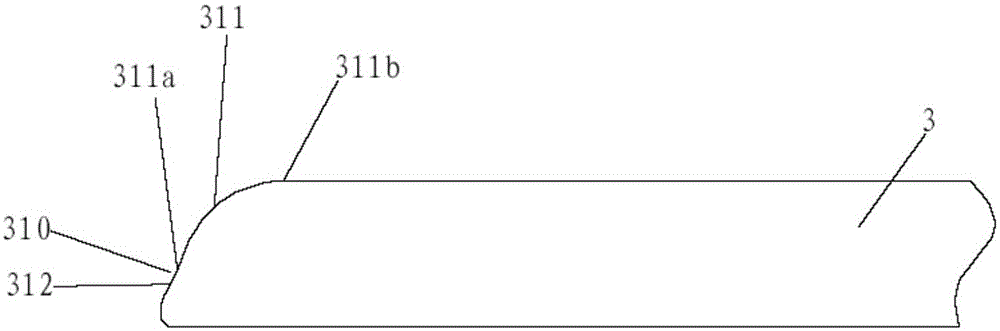

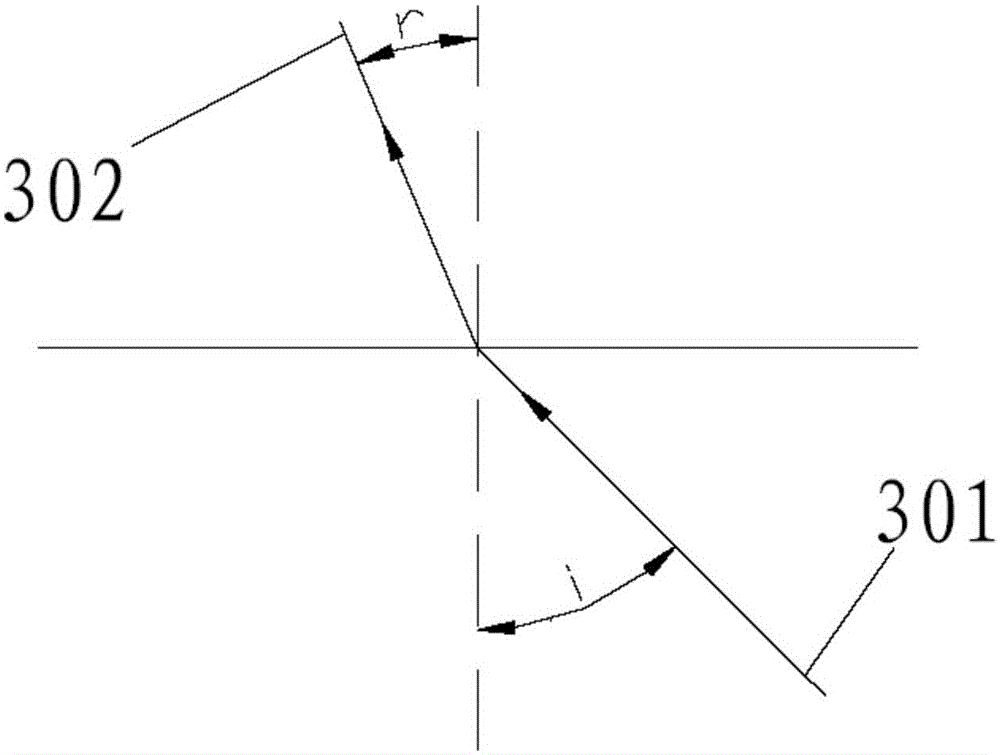

Touch screen with infrared rays transmitted inside screen body and method for identifying touch points

ActiveCN102622135ASolve the problem of suspension heightAchieve borderlessInput/output processes for data processingInfraredTouchscreen

The invention discloses a touch screen with infrared rays transmitted inside a screen body and a method for identifying touch points. In the touch screen, the infrared rays sent out by an infra-red emission unit ripe into the touch screen body, are totally reflected by an upper reflecting surface and a lower reflecting surface inside the touch screen body, and are transmitted into the infrared receiving unit. According to the invention, the infrared rays are transmitted inside the touch screen body by using the total reflection principle, and a touch body is enabled to be clung to the surface of the touch screen to generate touch response, so that the problem of touch floating height is solved; and since the infrared rays are transmitted inside the touch screen, the infra-red emission unit is not required to be placed on the surface of the touch screen. Therefore, an edge frame free touch screen is realized.

Owner:GENERALTOUCH TECH

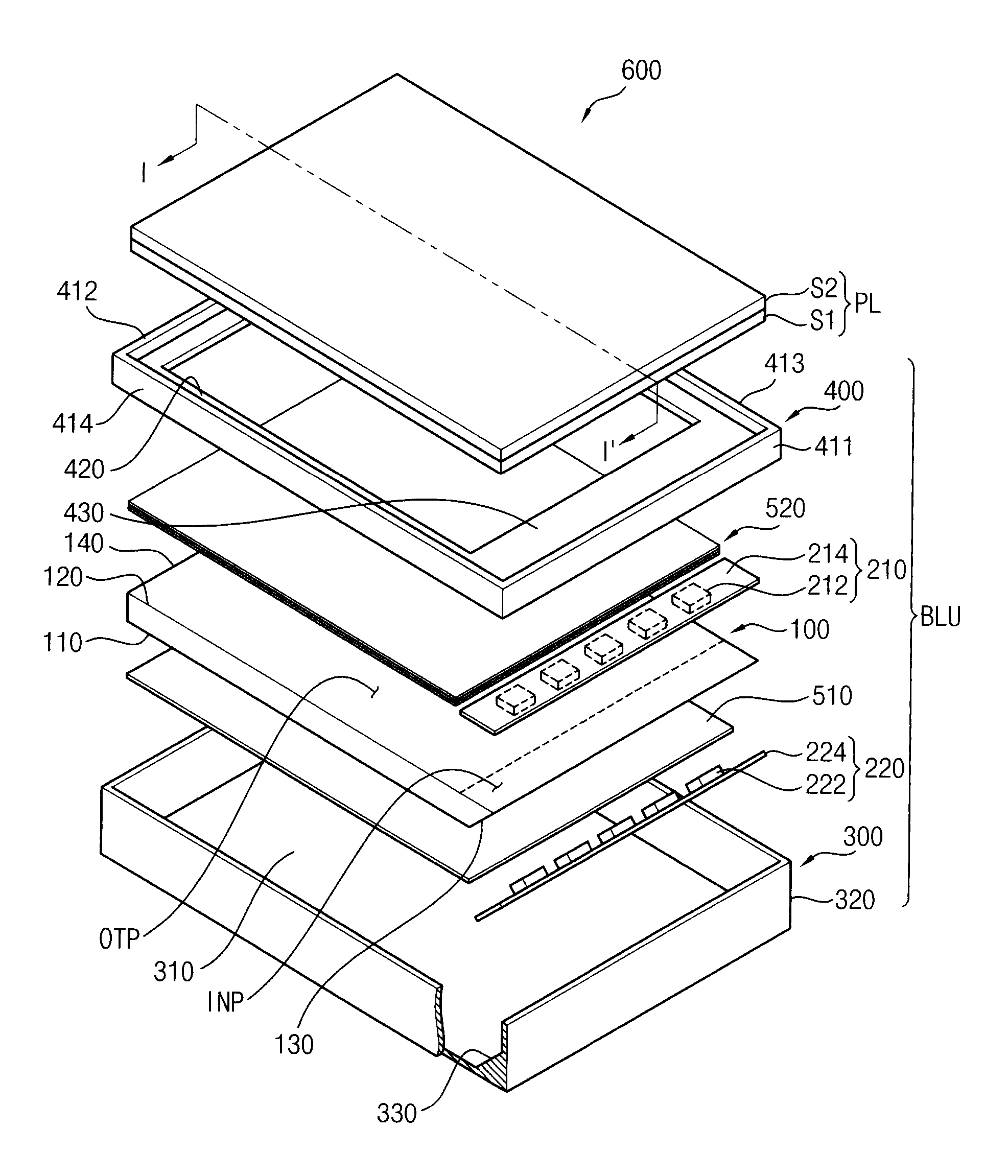

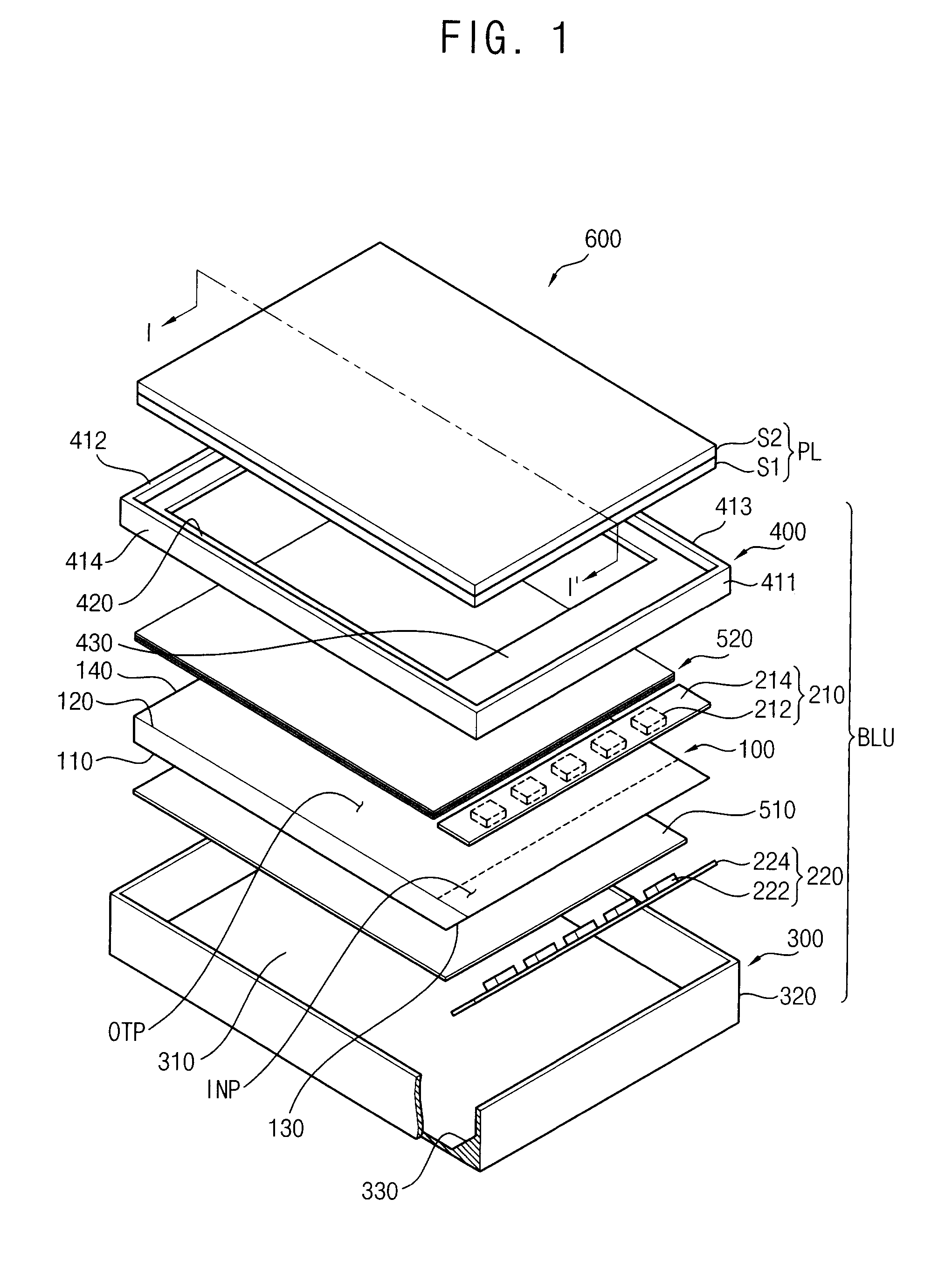

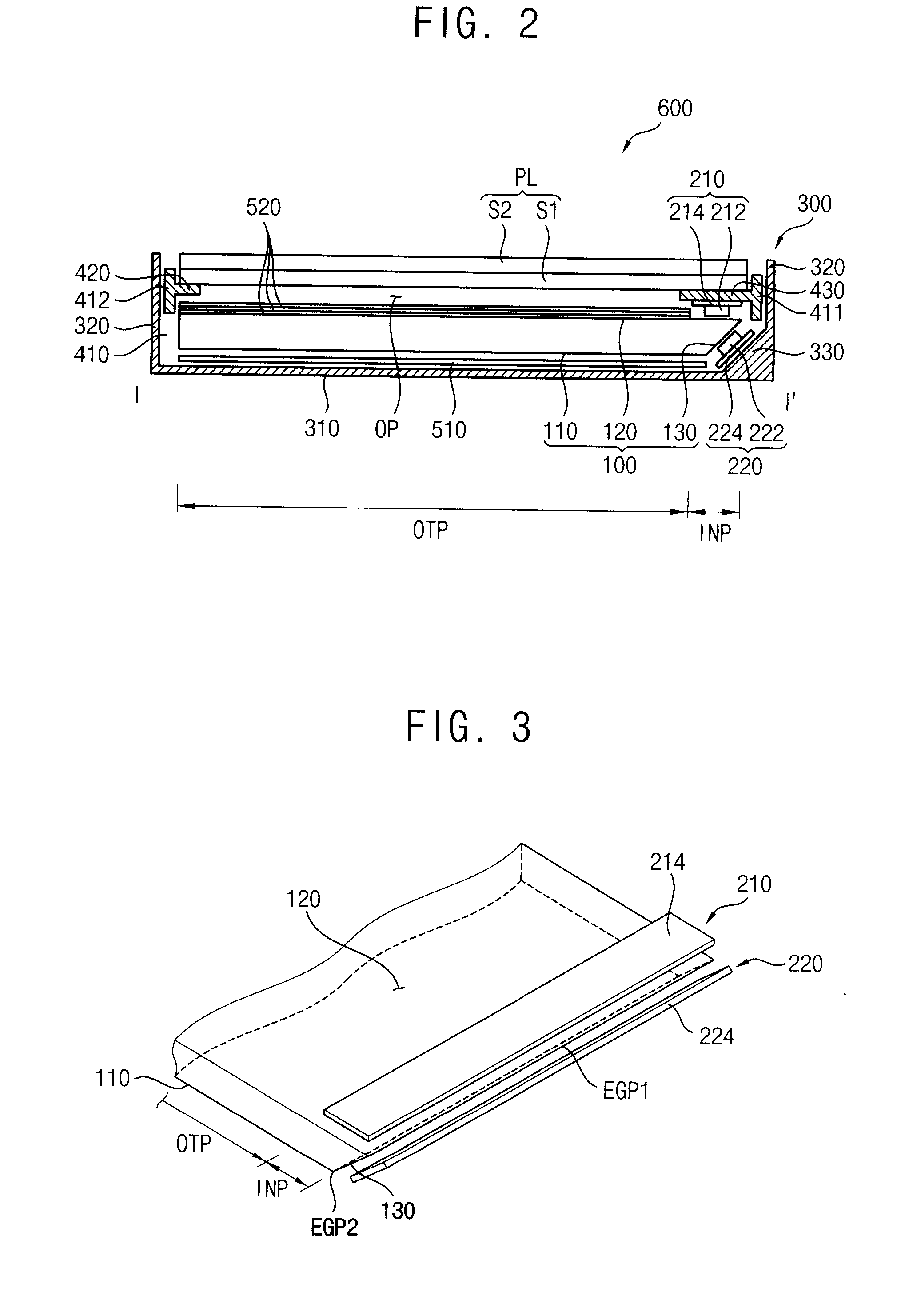

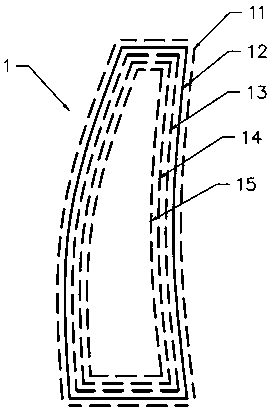

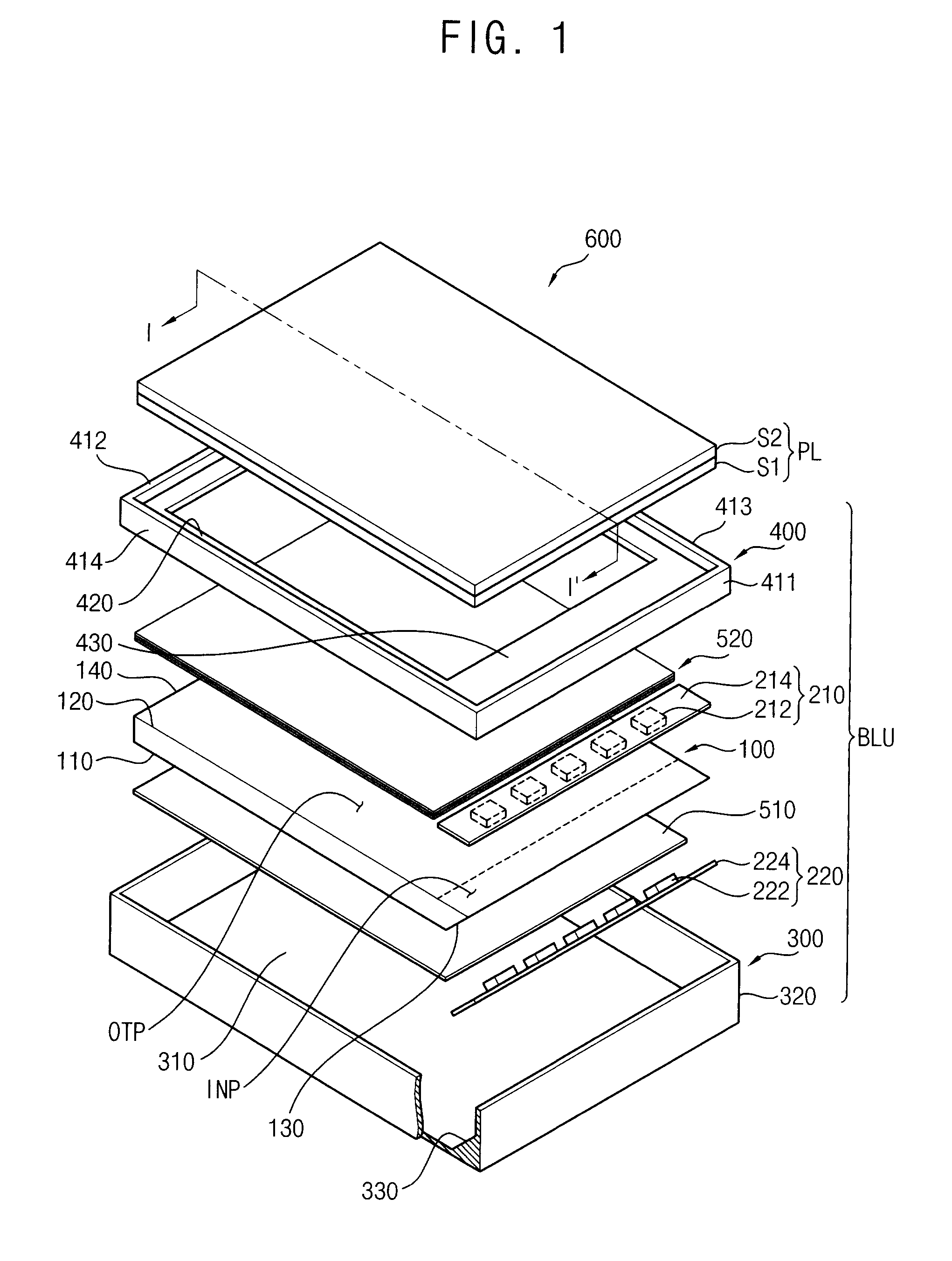

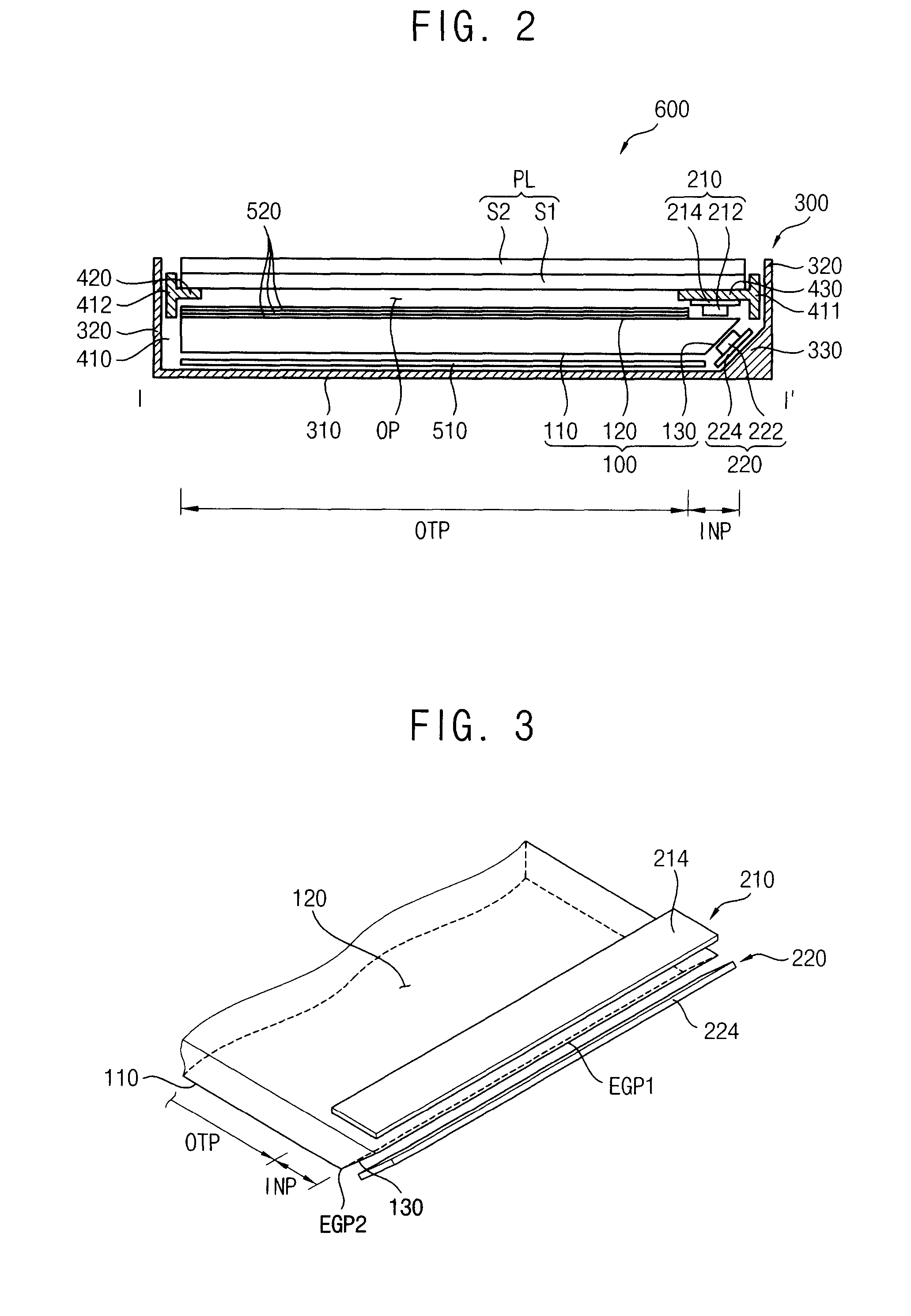

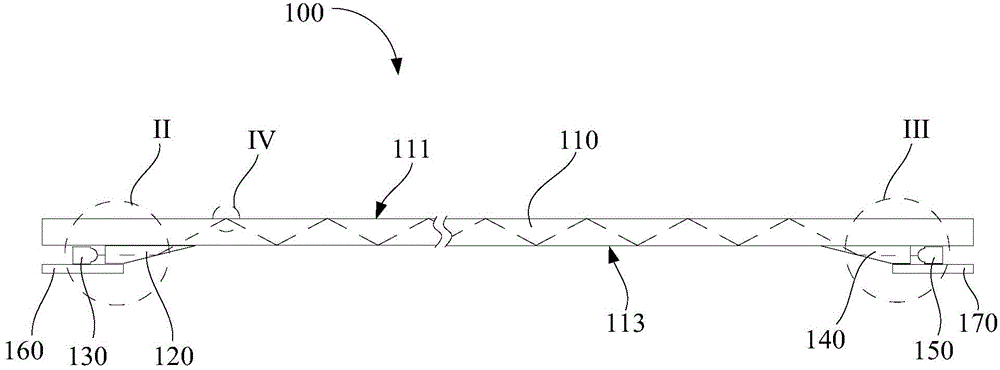

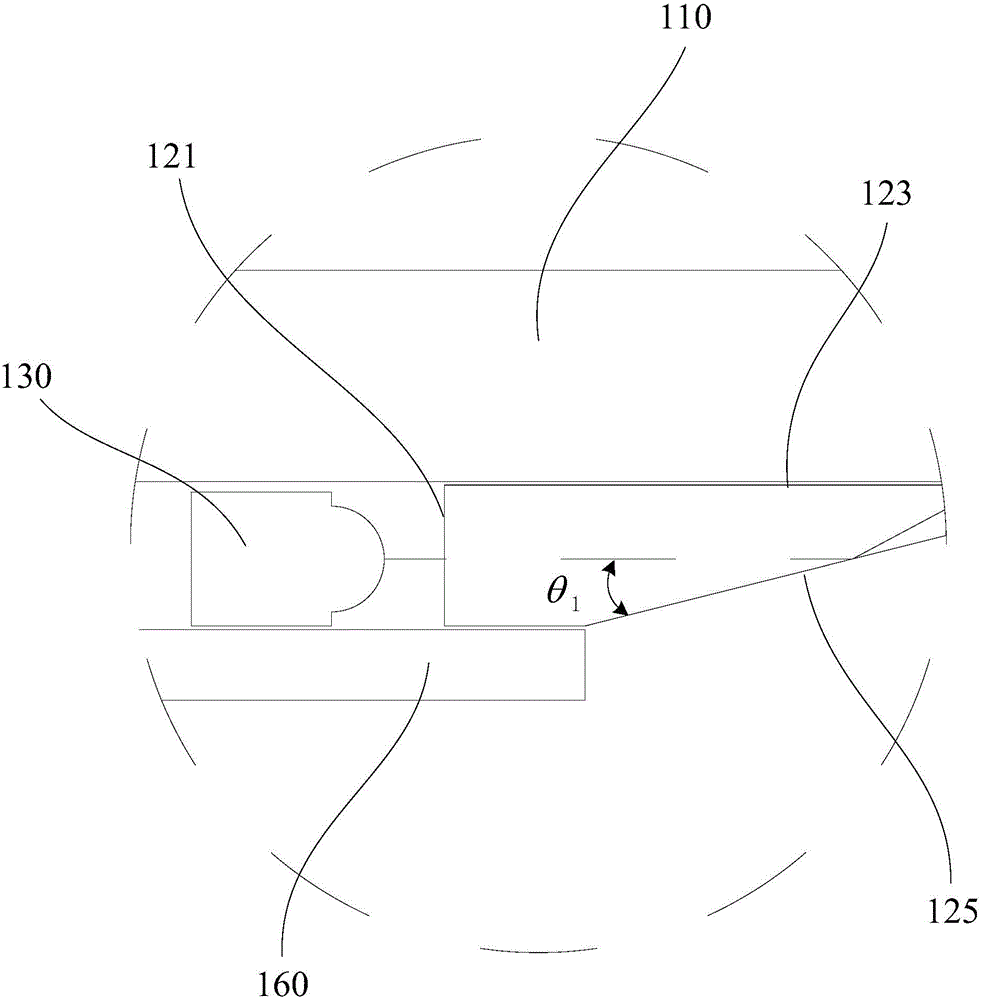

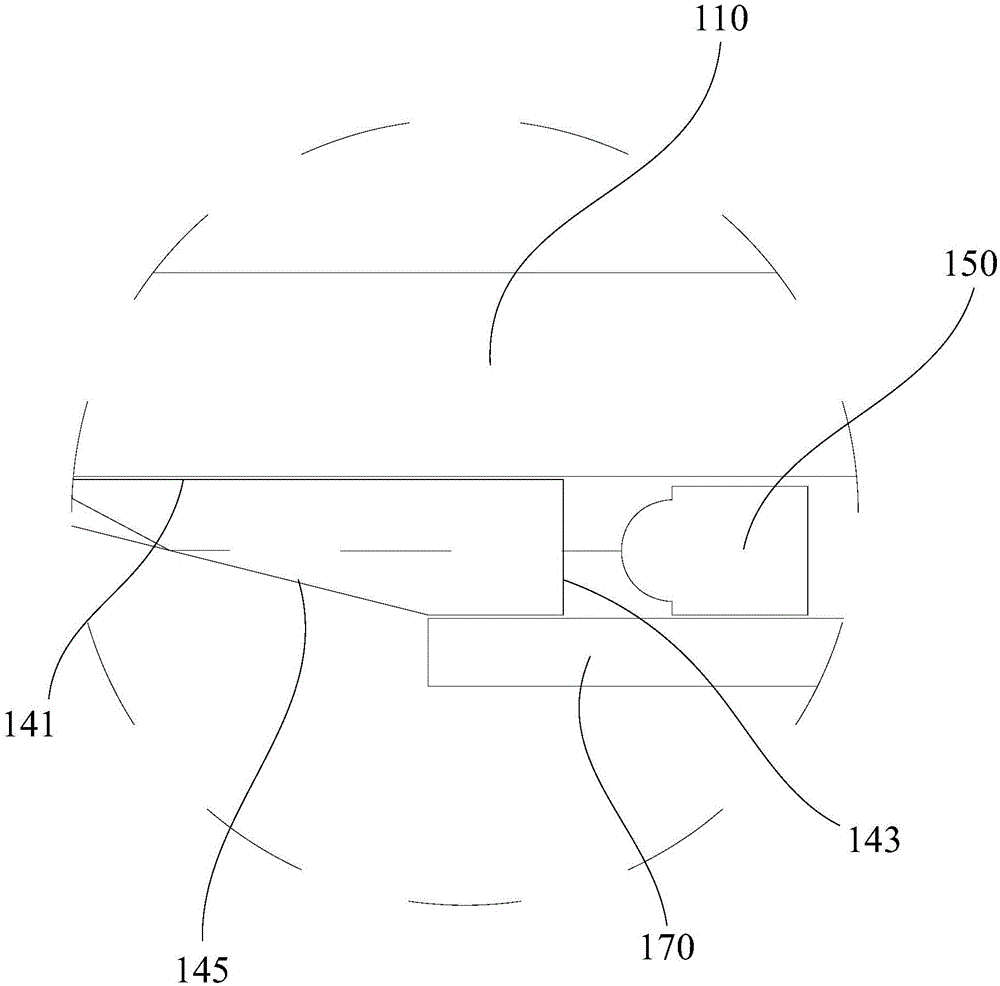

Light-emitting assembly and display apparatus having the same

InactiveUS20120230050A1Reduce manufacturing costReduce edge thicknessPlanar/plate-like light guidesInput/output processes for data processingLight guideEngineering

In a light-emitting assembly and a display apparatus having the light-emitting assembly, the light-emitting assembly includes a light guide plate, a first light-emitting module and a second light-emitting module. The light guide plate includes a first surface, a second surface facing the first surface and including a light incident portion and a light exiting portion, and a third surface connecting the first surface with the second surface and inclined toward the first surface. The first light-emitting module is on the light incident portion of the second surface and emits a first light to the light incident portion. The second light-emitting module faces the third surface and emits a second light having a wavelength different from the first light, to the third surface.

Owner:SAMSUNG DISPLAY CO LTD

Electronic device

The invention is applicable to the technical field of electronic equipment, and discloses electronic equipment. The electronic equipment comprises a body, a display module and a transparent panel. The display module and the transparent panel are connected to the body. The display module comprises a display area and a non-display area positioned on the lateral side of the display area. The transparent panel covers the display area and the non-display area. A light guide structure is arranged at a position, corresponding to the upper side of the non-display area, of the transparent panel and is used for refracting light rays emitted by the display area to the outside of the transparent panel from the inside of the transparent panel. The refractive index of the transparent panel is larger than 1. The electronic equipment has the advantages that through the light guide structure used for refracting the light rays emitted by the display area to the outside of the transparent panel from the inside of the transparent panel, the light rays are emitted from the light guide structure when being observed from the visual angle of a user, so that the electronic equipment can be enabled to have an extremely narrow edge or be free of a black edge and is attractive and elegant.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

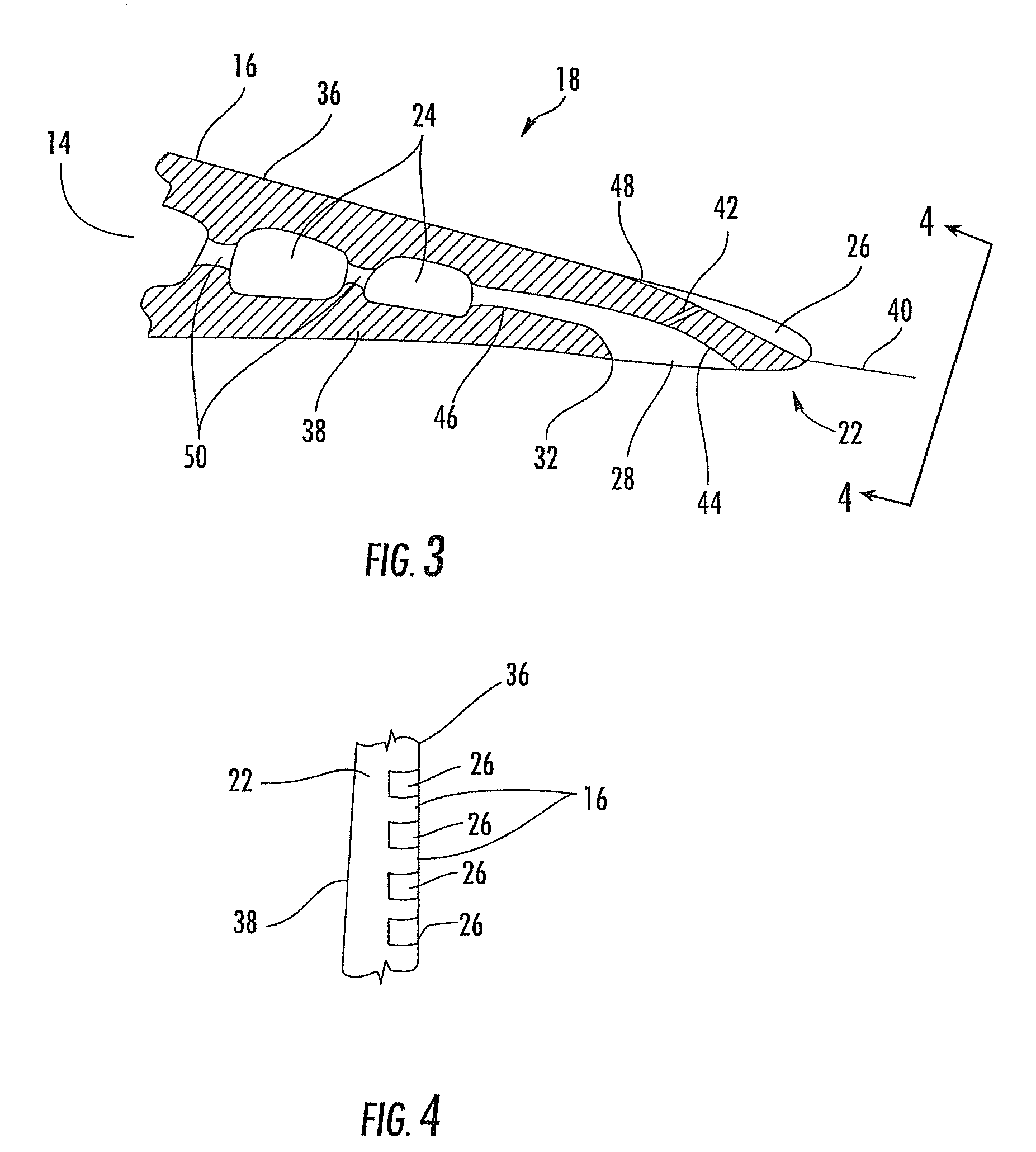

Turbine blade with multiple trailing edge cooling slots

A cooling system for a turbine airfoil of a turbine engine has a multiple suction side cooling slots extending from a front edge on the suction side to the center of the trailing edge or even to the pressure side of the center line and a pressure side cooling slot curving to a pressure side outlet forward of the trailing edge and having a front pressure side lip that is aligned with or forward of the front edge of the suction side cooling slots. The suction side cooling slots receive cooling flow from the pressure side cooling slots through a boundary layer bleed valve, which is also aligned with or rearward of the pressure side lip. The cooling system may also combine double impingement cooling with these features. The cooling system minimizes shear mixing, reduces hot spots and can reduce the trailing edge thickness, resulting in more efficient stage performance and extended operational life.

Owner:SIEMENS ENERGY INC

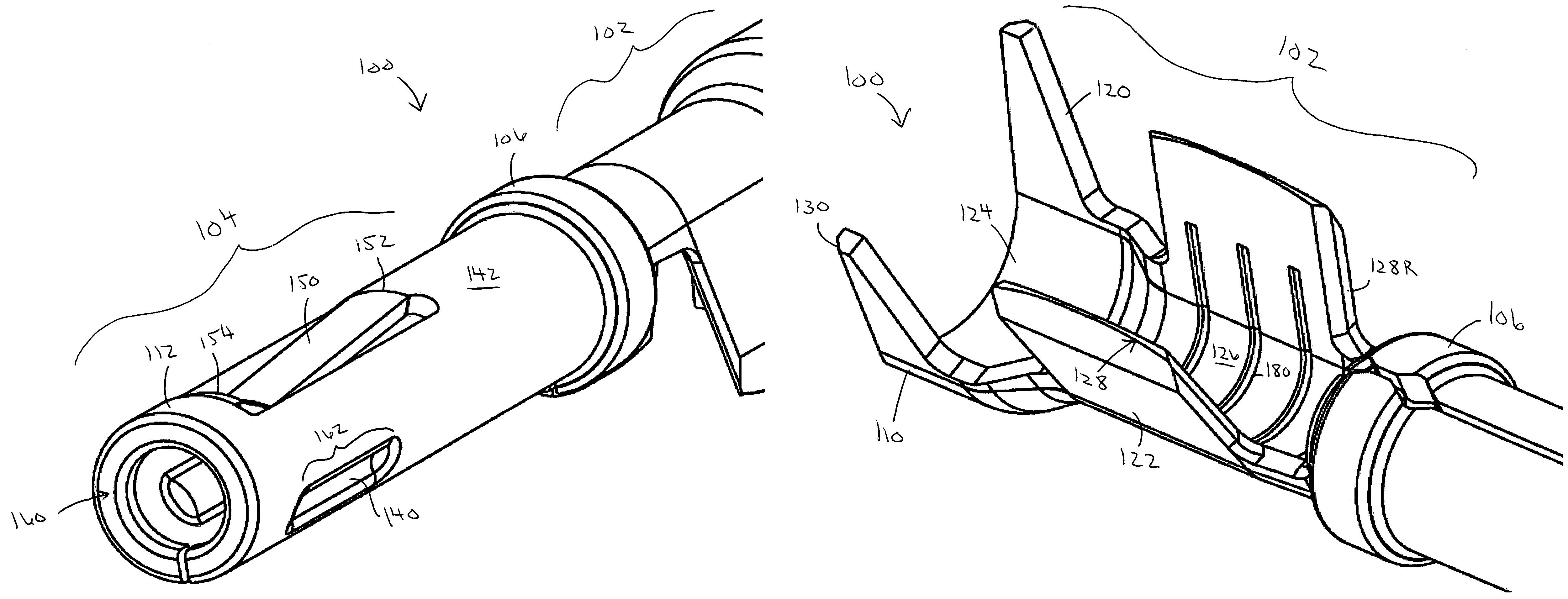

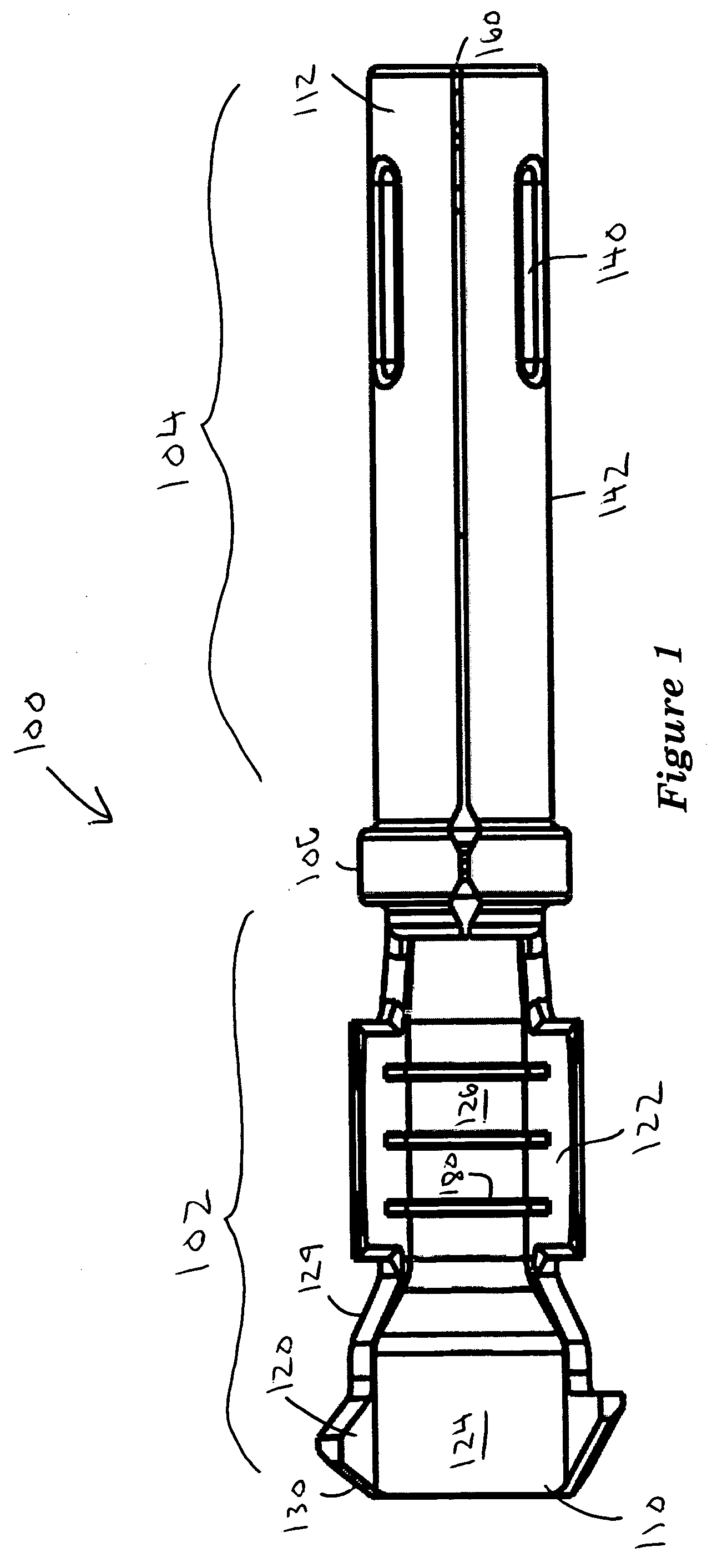

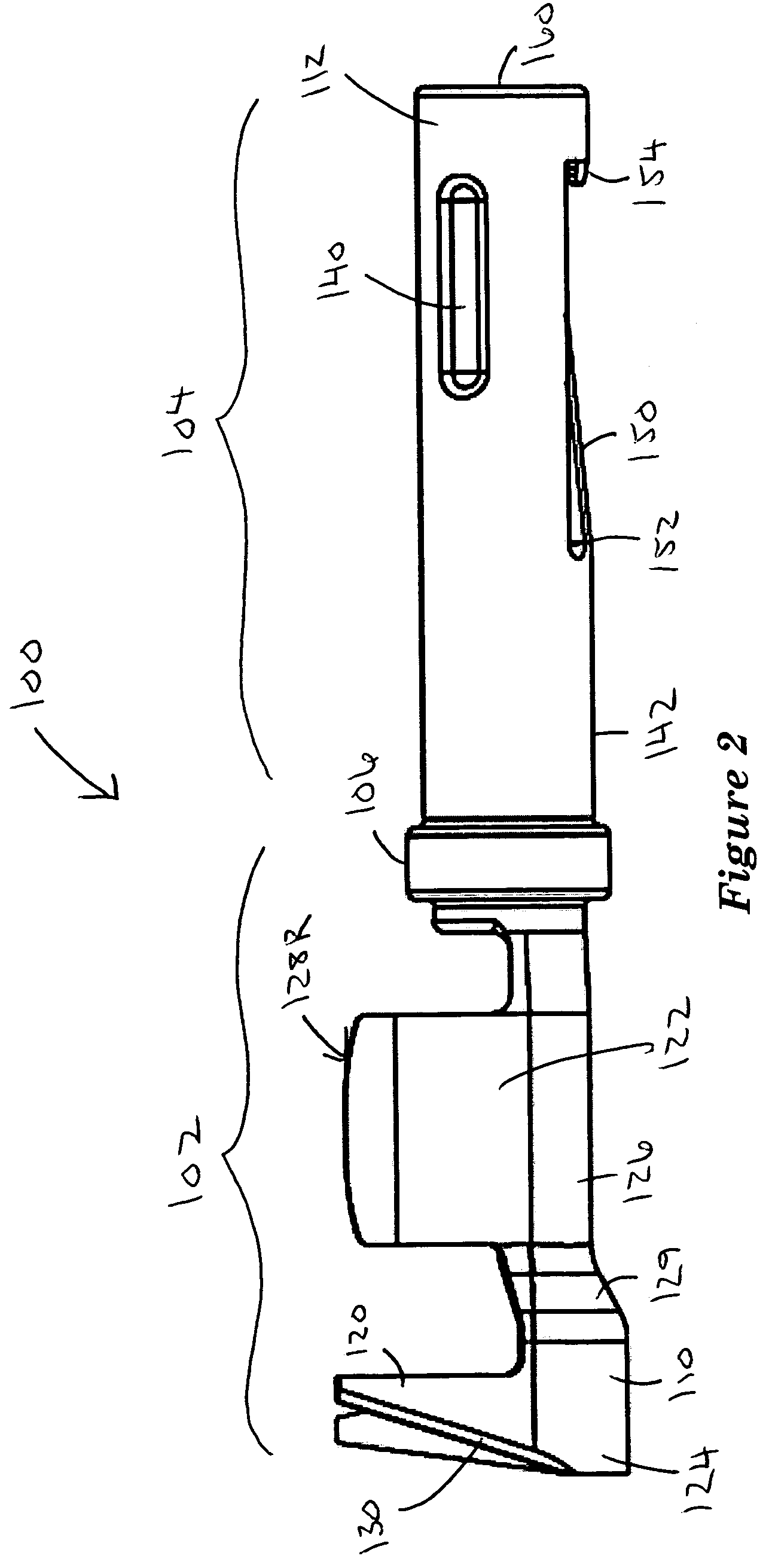

Sleeveless stamped and formed socket contact

ActiveUS7249983B2Reduce edge thicknessPrevent movementCoupling contact membersConnections effected by permanent deformationFluteCantilever

An electrical contact includes a crimping section for securing a wire and a flute section for receiving a pin. The flute section includes fixed engagement members and a resilient cantilever member that engages the pin within the flute section.

Owner:DEUT ENGINEERED CONNECTING DEVICES

Wafer treatment solution for edge-bead removal, edge film hump reduction and resist surface smooth, its apparatus and edge-bead removal method by using the same

ActiveUS20160056049A1Improve efficiencyReduce harmDetergent mixture composition preparationSemiconductor/solid-state device manufacturingWaferingFluorine containing

The present disclosure provides a wafer treatment solution for edge-bead removal, edge film hump reduction and resist surface smooth. The wafer treatment solution includes a solution and a fluorine-containing additive mixed in the solution. The fluorine-containing additive has a following formula (I): Rf—X—(CH2CH2O)m—R1 (I); or a following formula (II):An apparatus and a method by using the wafer treatment solution are also provided herein.

Owner:KE I SHAN

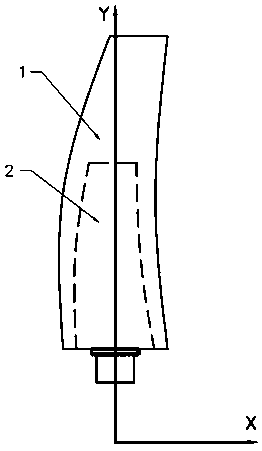

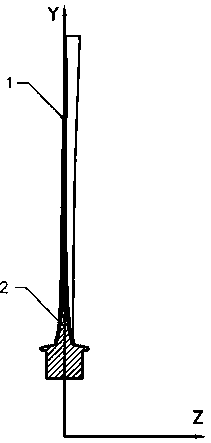

Designing and manufacturing method of composite blade and composite blade

The invention provides a designing and manufacturing method of a composite blade. Pre-forming sheets are paved on the two sides of a metal framework, and the composite blade of a sandwich structure isformed after curing compounding of curing equipment. Through the manner of manufacturing the composite blade through a composite of the pre-forming sheets, the manufacturing process can be simplified, cost can be reduced, and good integrity and bonding strength are achieved. The invention further relates to the composite blade. The composite blade comprises the composite and the metal framework.The metal framework is pre-manufactured to be in a blade shape, the pre-forming sheets formed by multiple layers of prepreg fiber cloth are paved outside the metal framework, through holes are formedin the metal framework, carbon fiber wiring harnesses used for fixing the metal framework and the pre-forming sheets on the two sides are wound in the through holes, and the composite blade is obtained through curing of the curing equipment. The composite blade has the advantage that the composite blade cannot be screwed or twisted or bent under the limiting condition, weather resistance is good,certain impact resistance is achieved, and the special requirements of aviation and ships can be met.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Light-emitting assembly and display apparatus having the same

InactiveUS8545087B2Reduce edge thicknessReduce power consumptionPlanar/plate-like light guidesInput/output processes for data processingLight guideEngineering

In a light-emitting assembly and a display apparatus having the light-emitting assembly, the light-emitting assembly includes a light guide plate, a first light-emitting module and a second light-emitting module. The light guide plate includes a first surface, a second surface facing the first surface and including a light incident portion and a light exiting portion, and a third surface connecting the first surface with the second surface and inclined toward the first surface. The first light-emitting module is on the light incident portion of the second surface and emits a first light to the light incident portion. The second light-emitting module faces the third surface and emits a second light having a wavelength different from the first light, to the third surface.

Owner:SAMSUNG DISPLAY CO LTD

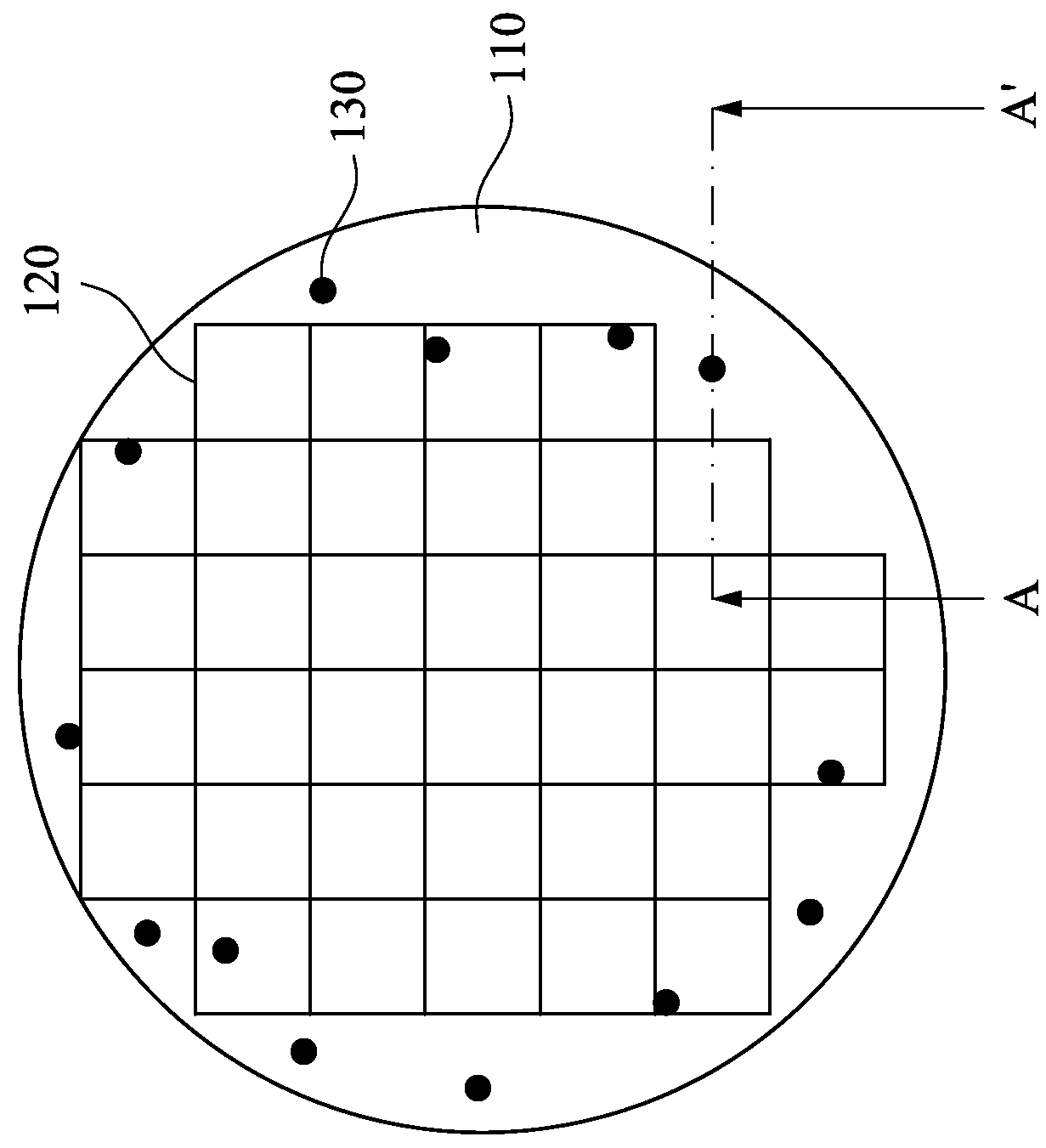

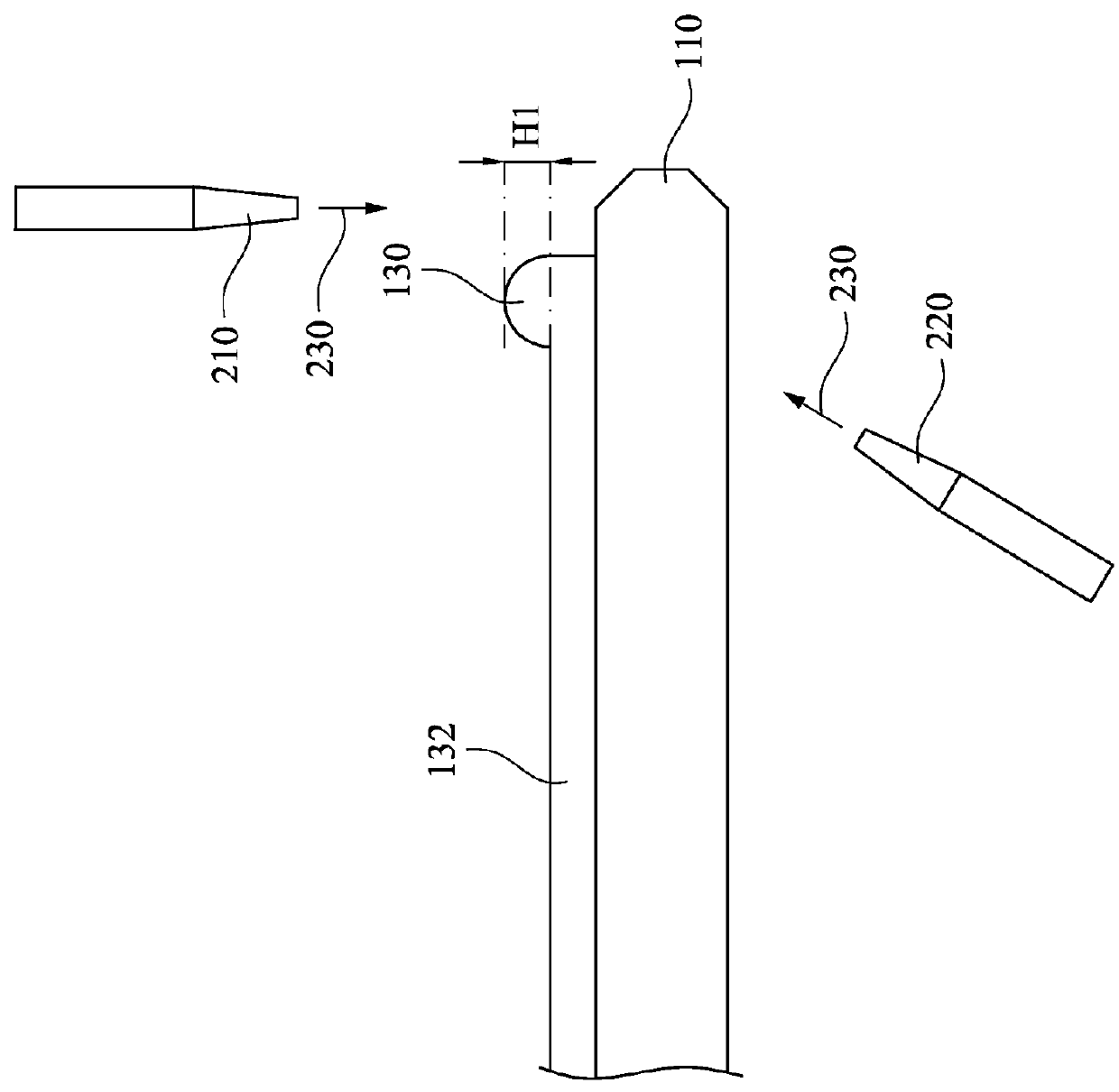

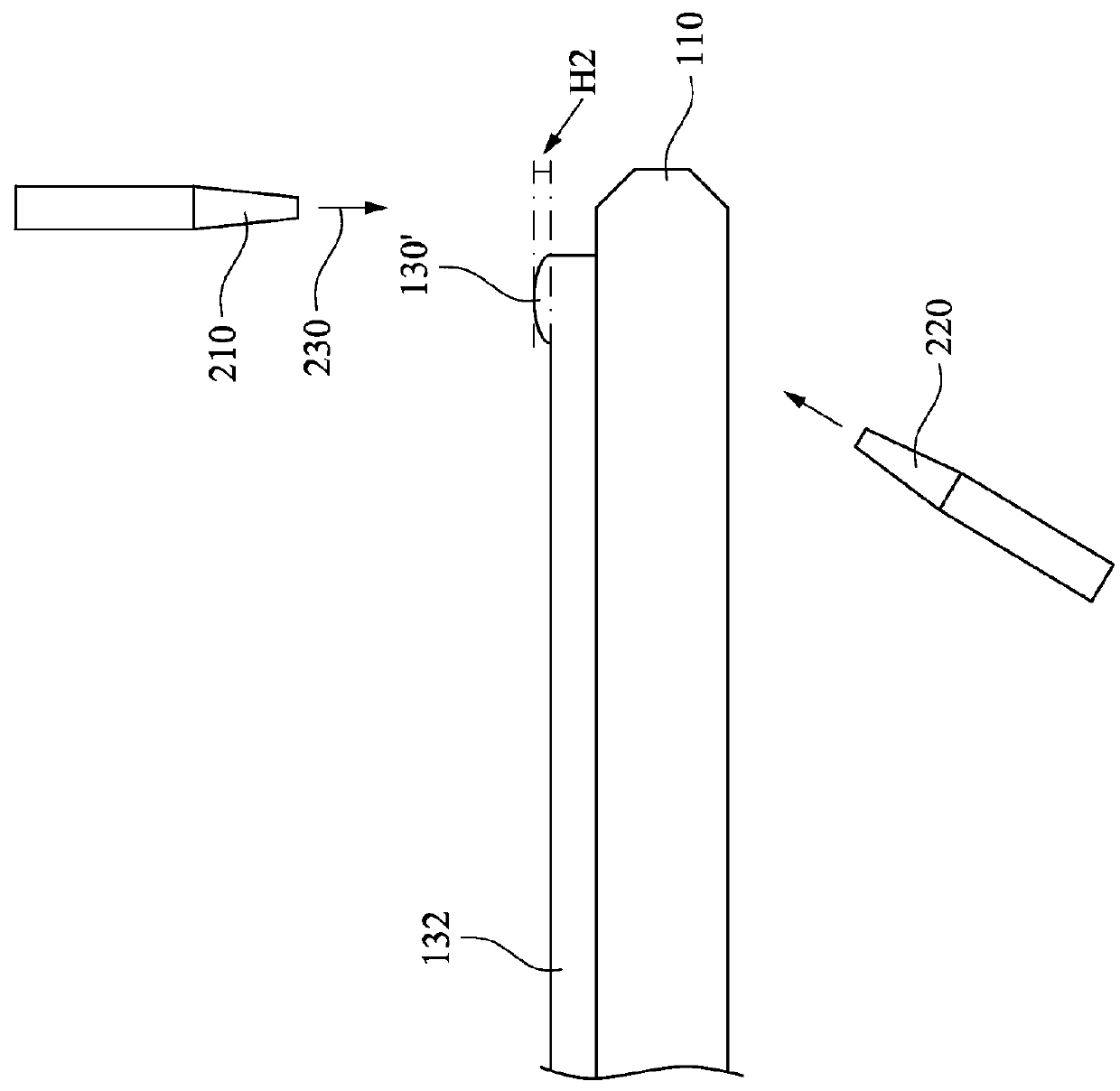

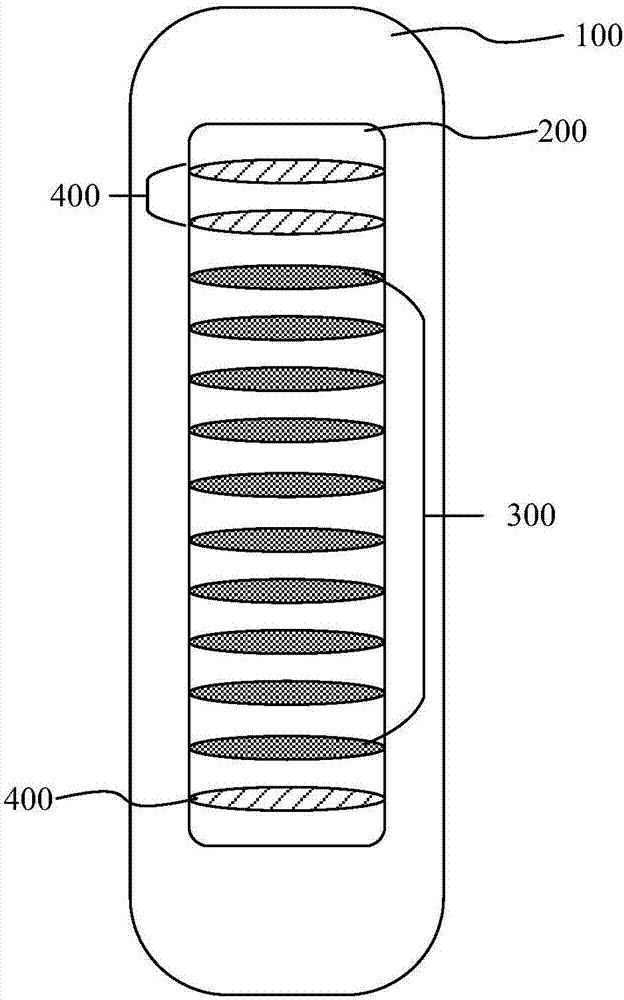

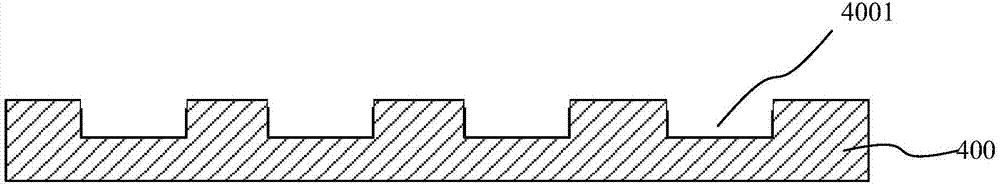

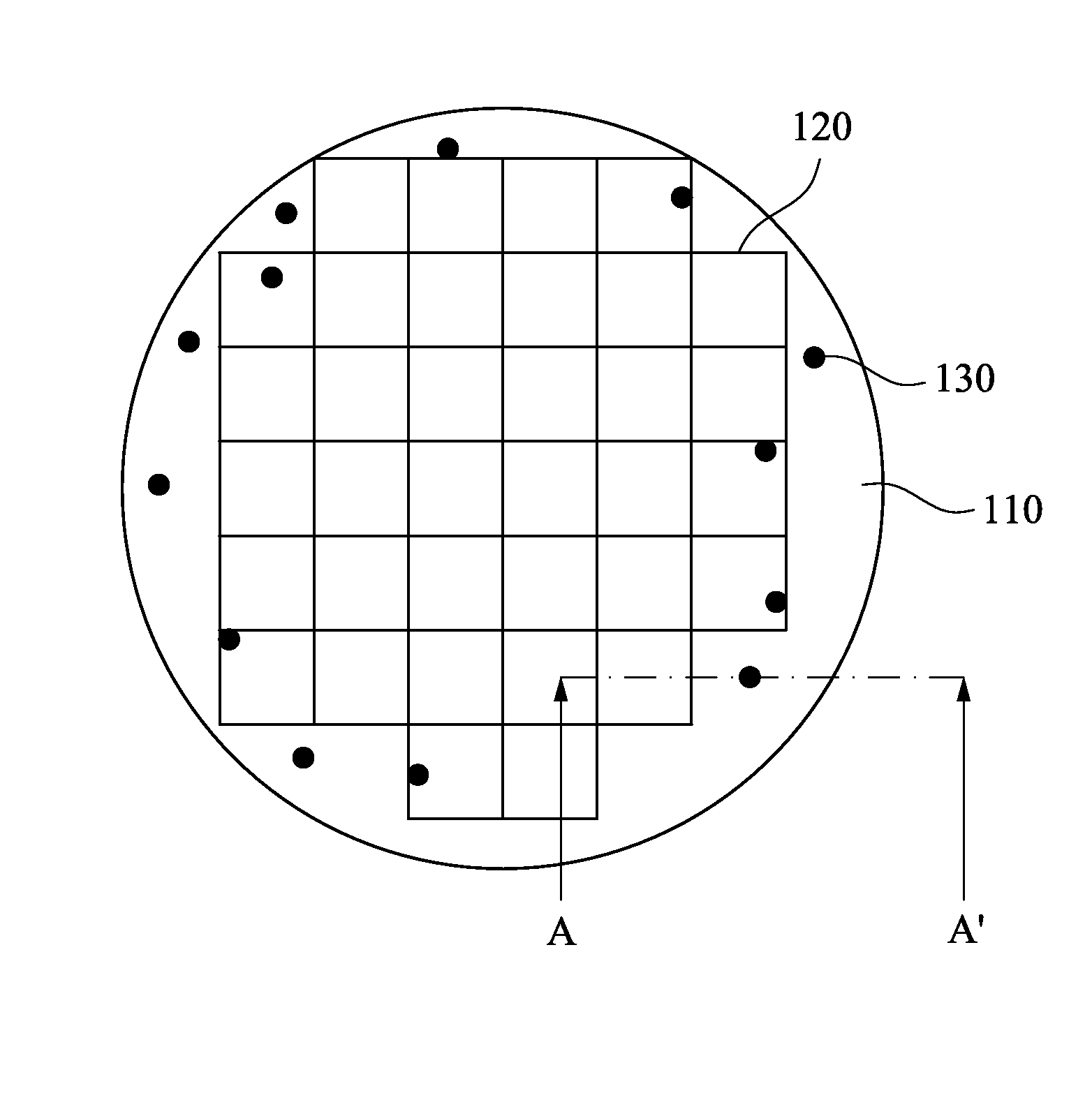

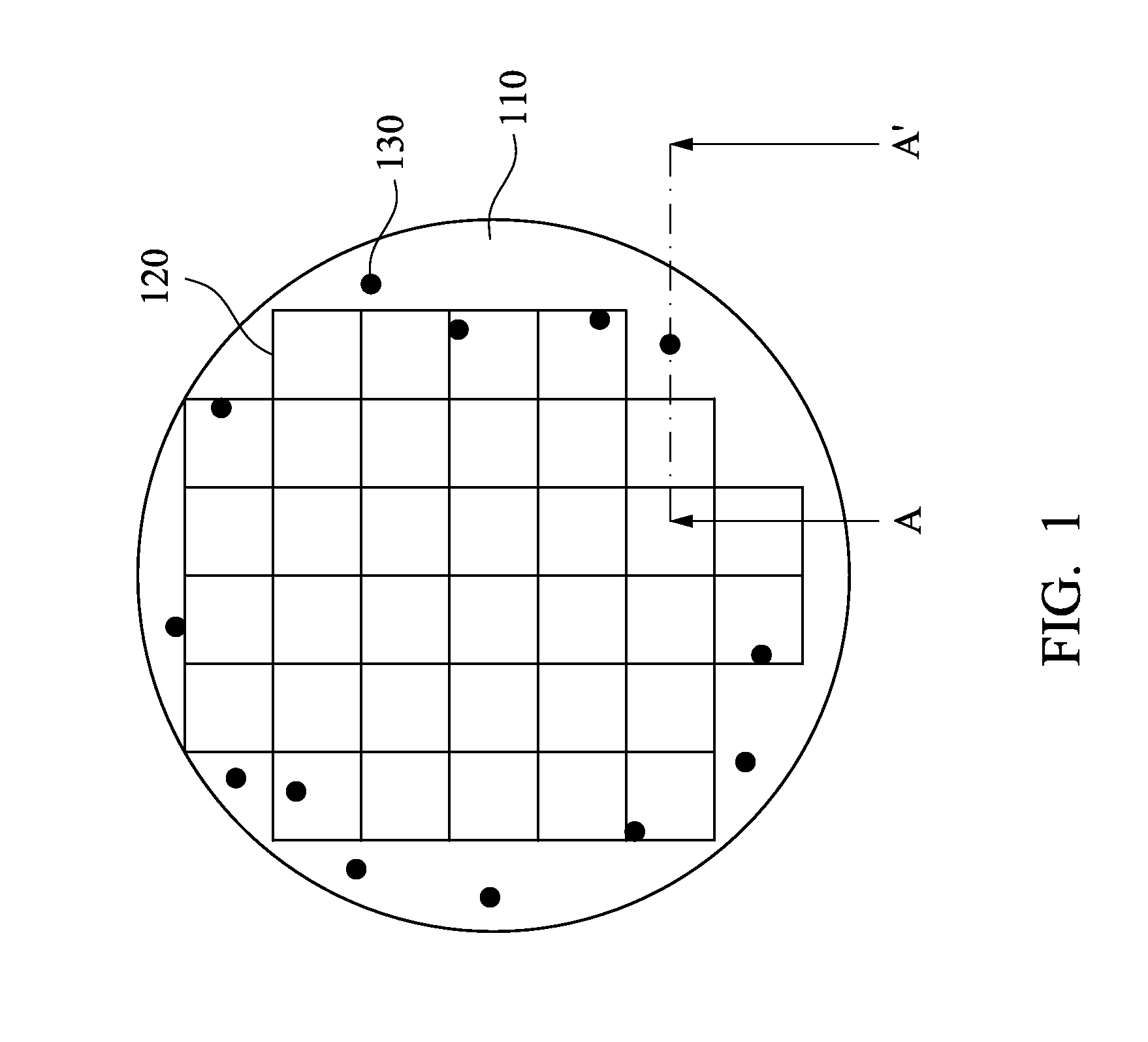

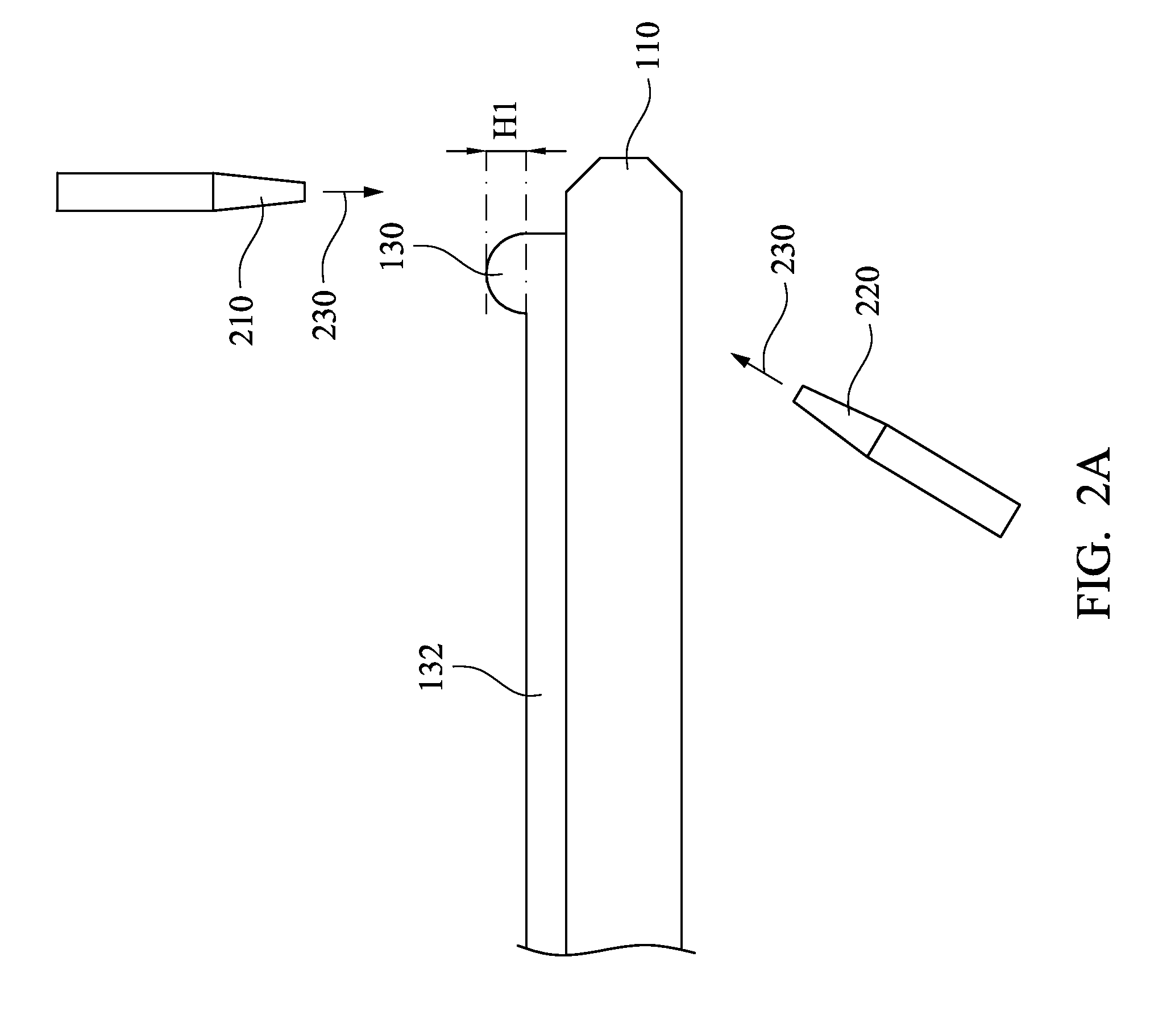

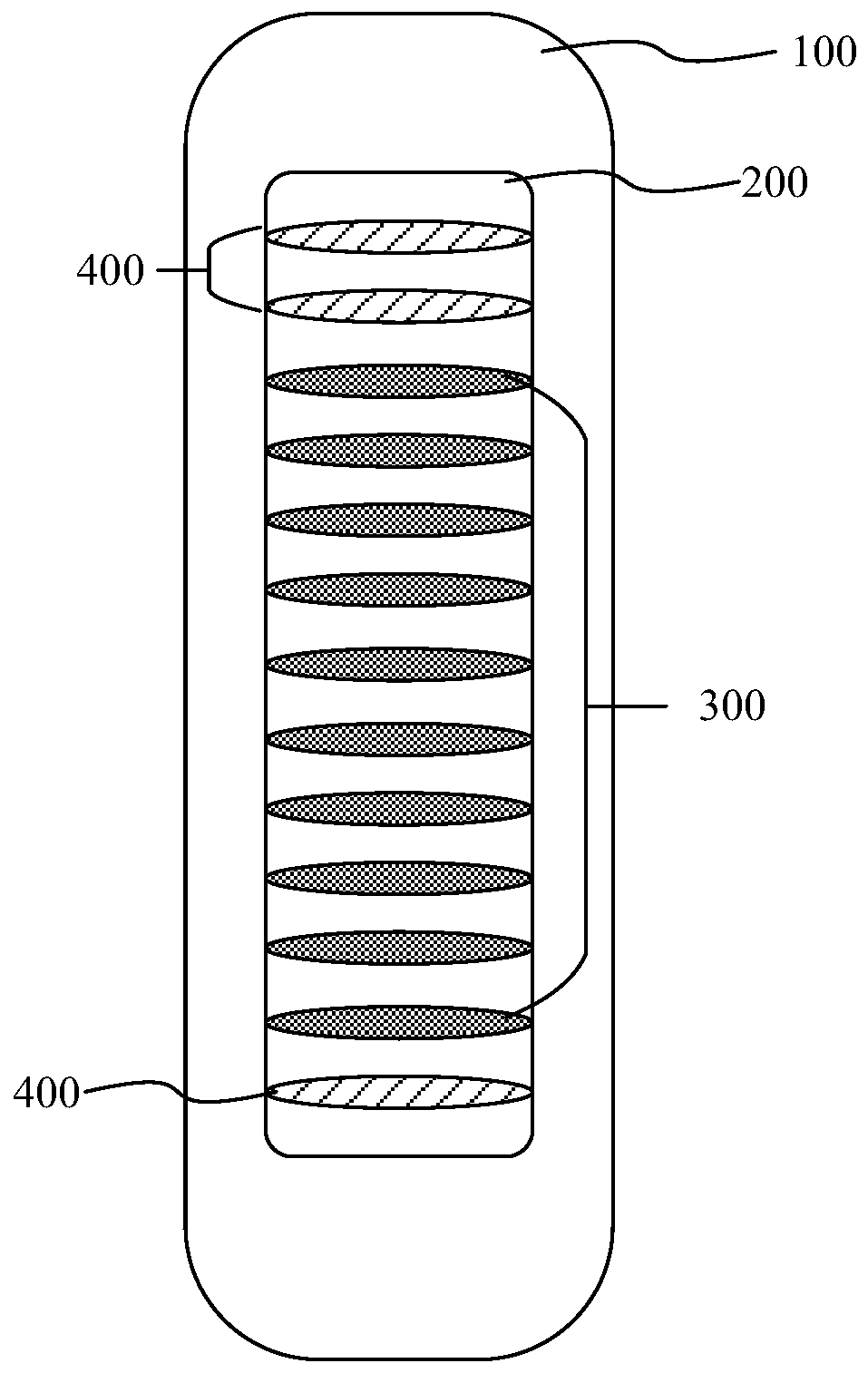

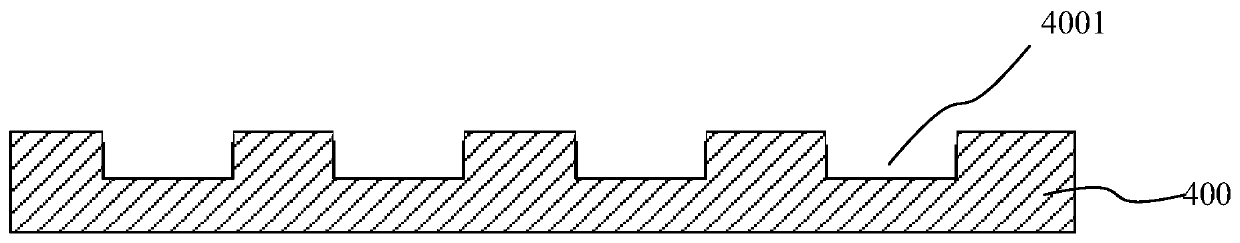

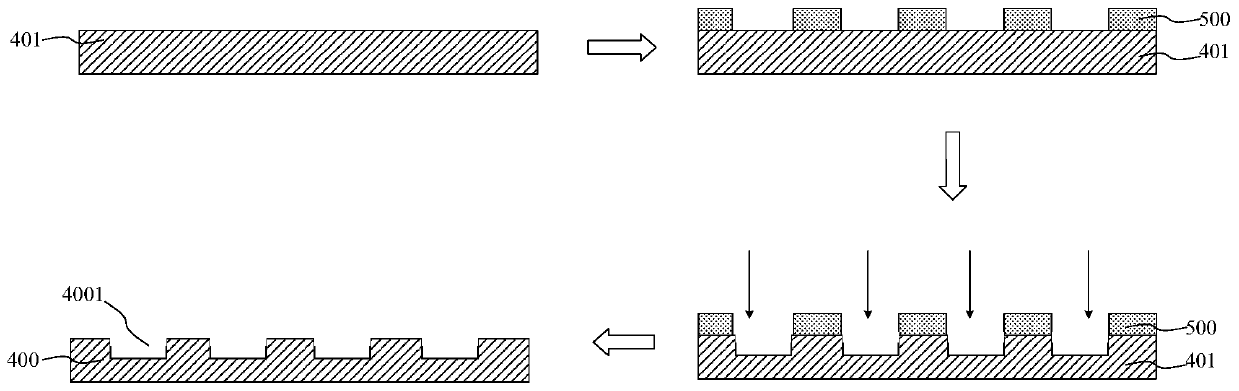

Method for improving deposition uniformity of thin films

ActiveCN107881486AImproves deposition uniformityIncrease the adsorption areaChemical vapor deposition coatingSurface structureElectrical and Electronics engineering

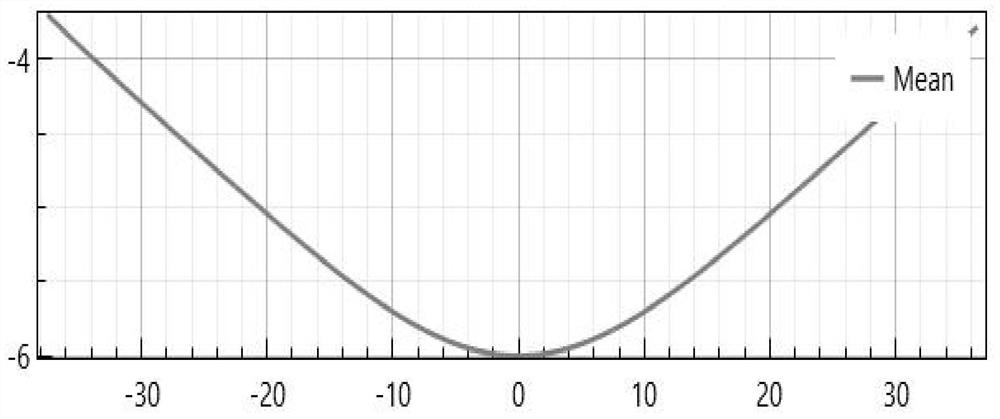

The invention provides a method for improving the deposition uniformity of thin films. The method comprises the following steps that a plurality of pieces of wafers are borne by using a wafer cassette; the wafer cassette is provided with a head part and a tail part, and the multiple pieces of wafers are arranged between the head part and the tail part of the wafer cassette; blocking and controlling sheets are arranged between the multiple pieces of wafers and the head part of the wafer cassette as well as / or the multiple pieces of wafers and the tail part of the wafer cassette; and the wafercassette bearing the wafers and the blocking and controlling sheets is placed in a reaction furnace tube and subjected to thin film deposition, wherein the blocking and controlling sheets have an uneven surface structure. According to the method for improving the deposition uniformity of the thin films, the blocking and controlling sheets with the uneven surface structure are guided in and replace even blocking and controlling sheets in the prior art, the gas adsorption capacity is improved by increasing the adsorption area of the blocking and controlling sheets, and the edge thickness of a product adjacent to the blocking and controlling sheets can be reduced effectively, thus the film thickness uniformity of a chip can be improved effectively, and a curve of the yield loss of the edge of the wafer cassette position is smoothed to improve the product yield.

Owner:CHANGXIN MEMORY TECH INC

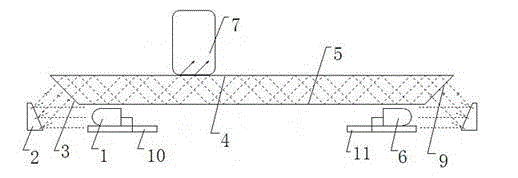

Touch screen realized based on total reflection wave technology and touch display device with same

InactiveCN104598081ASolve the problem of suspension heightRealize no convex framePrismsOptical light guidesLight guideDisplay device

A touch screen realized based on a total reflection wave technology comprises a transparent touch substrate, a first light guiding device, a touch control light source, a second light guiding device and a light receiver, wherein the touch substrate comprises an upper surface and a lower surface opposite to the upper surface in parallel; the upper surface is a touch surface; the first light guiding device is arranged below the lower surface of the touch substrate; the touch control light source is arranged below the lower surface of the touch substrate and close to the first light guiding device; the second light guiding device is arranged below the lower surface of the touch substrate; the light receiver is arranged below the lower surface of the touch substrate; the light receiver and the touch control light source are located below the two opposite sides of the touch substrate respectively; the light receiver right faces the second light guiding device; the touch control light source right faces the first light guiding device. The touch screen has the advantages that touch suspension height does not exist, the capacity of resisting intense light interference is high, no wider and higher edge protrusion exist, and narrow edge design is facilitated. The invention further provides a touch display device with the touch screen.

Owner:李达

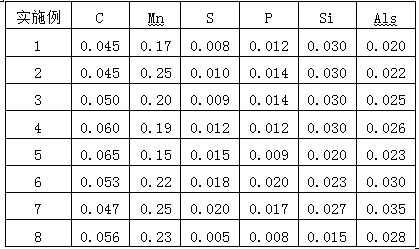

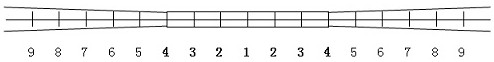

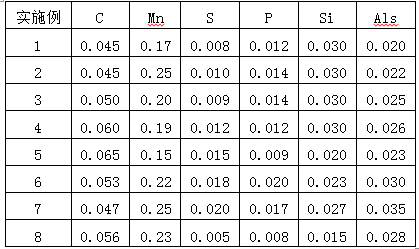

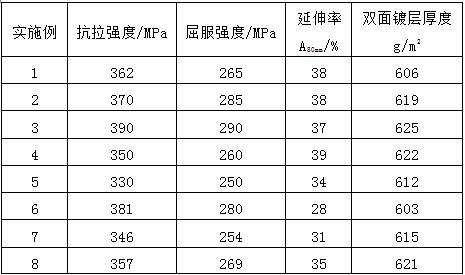

Ultra-thick coating hot galvanized steel strip for underground pipe gallery corrugated pipe and production method thereof

ActiveCN110684929AReduce the temperatureReduce core heatHot-dipping/immersion processesStrip steelAir knife

The invention discloses an ultra-thick coating hot galvanized steel strip for an underground pipe gallery corrugated pipe and a production method thereof. The hot galvanized steel strip comprises thefollowing chemical components of, in percentage by mass, 0.045%-0.065% of C, 0.15%-0.25% of Mn, less than or equal to 0.020% of S, less than or equal to 0.020% of P, less than or equal to 0.03% of Si,greater than or equal to 0.020% of Als, and balance iron and inevitable impurities; the production method comprises converter smelting, LF refining, continuous casting , hot rolling, cold rolling andgalvanizing processes. According to the ultra-thick coating hot galvanized steel strip for the underground pipe gallery corrugated pipe and the production method thereof, proper mechanical propertiesof the steel strip are guaranteed through reasonable component design and hot rolling and galvanizing annealing process design; and through reducing the height of an air knife, increasing the distance between a knife lip and the strip steel and sectional control measures of the opening degree of the air knife lip, the generation of zinc rhyolite and edge thickness defects is inhibited, the requirement of the underground pipe gallery industry on the ultra-thick coating hot galvanized steel strip is met, and remarkable economic benefits are achieved.

Owner:TANGSHAN IRON & STEEL GROUP +1

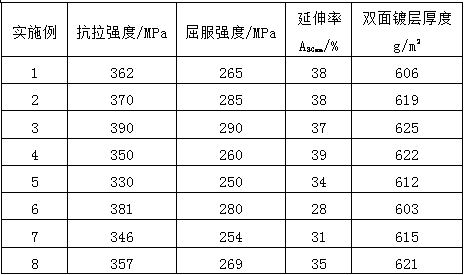

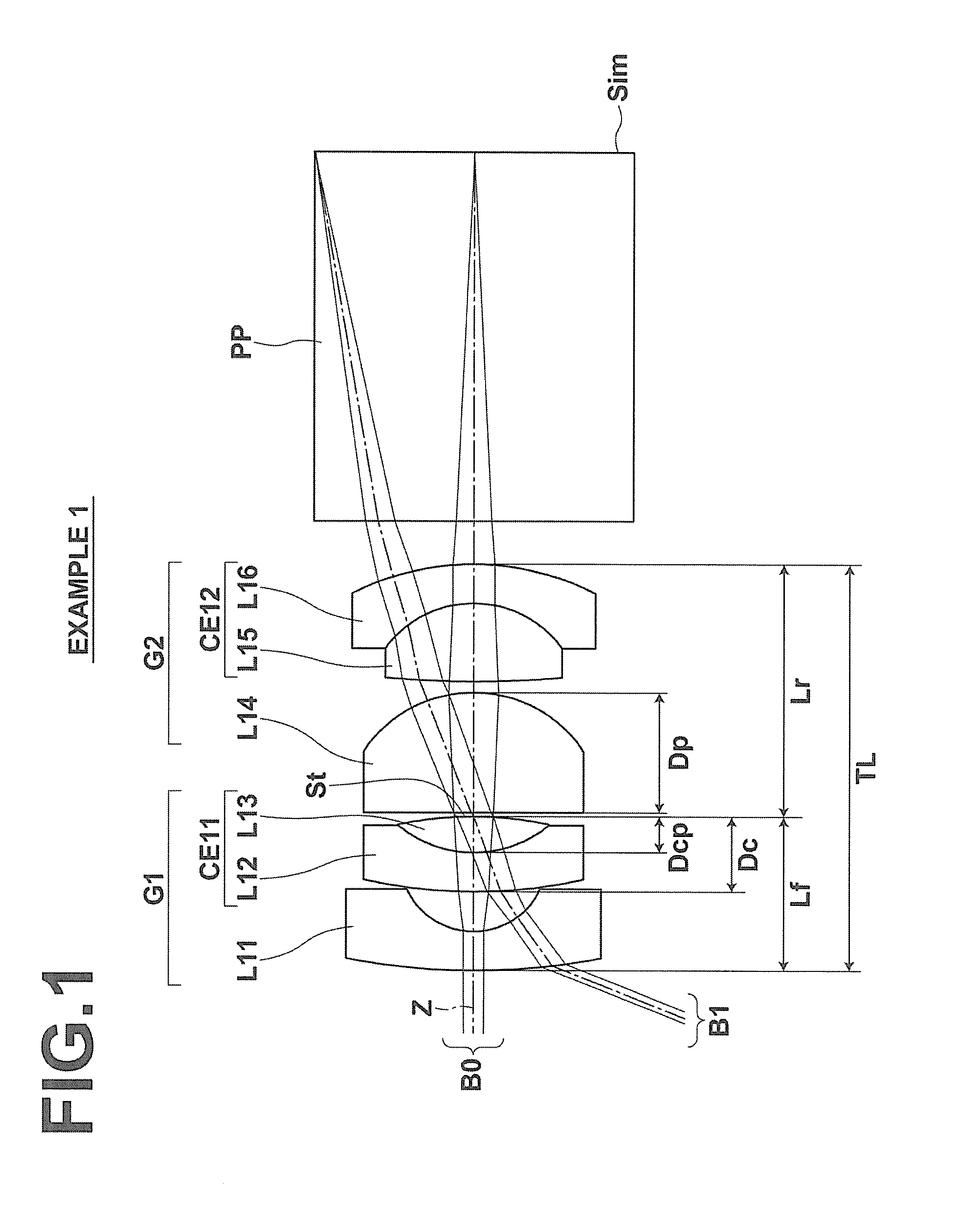

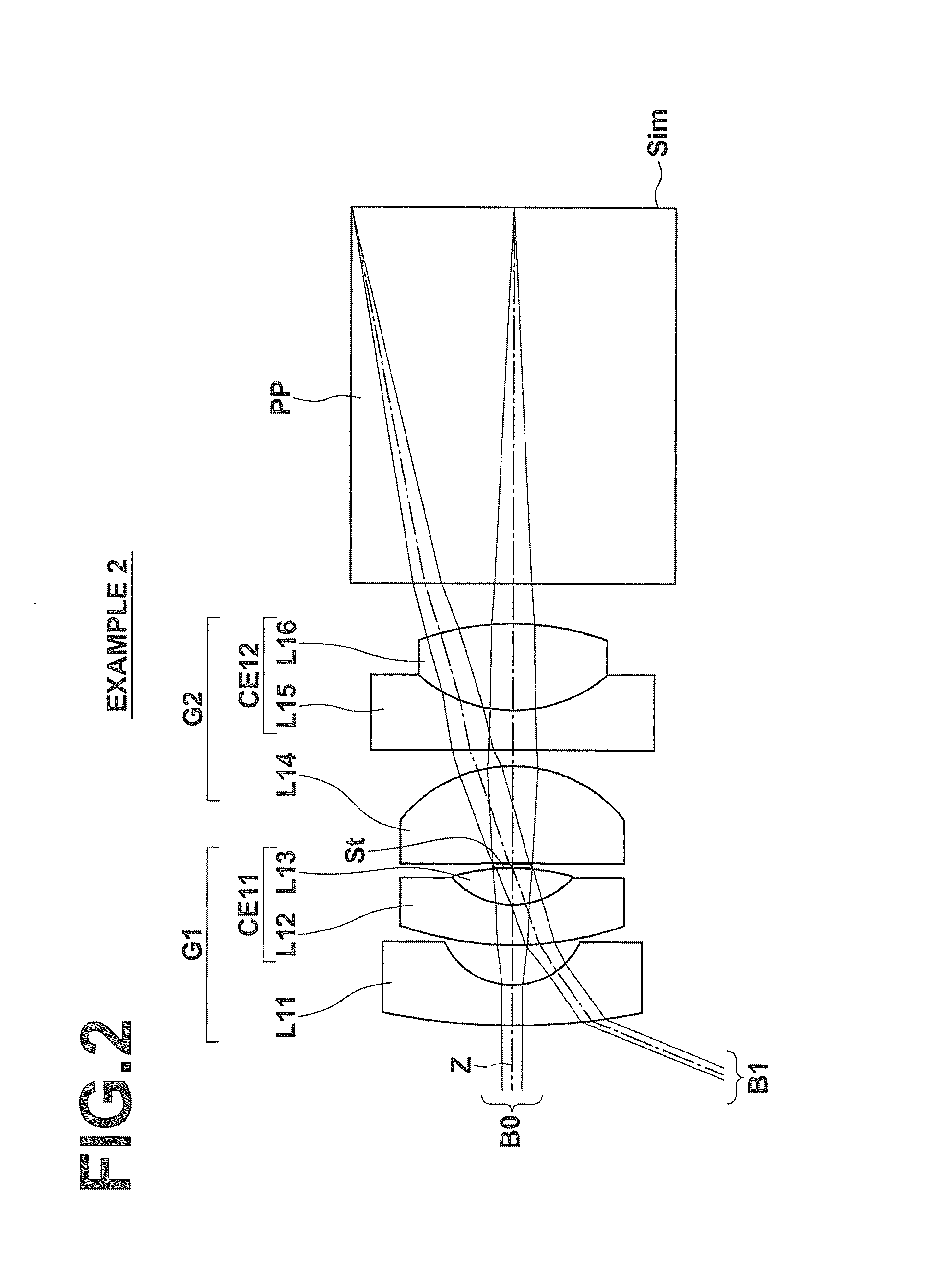

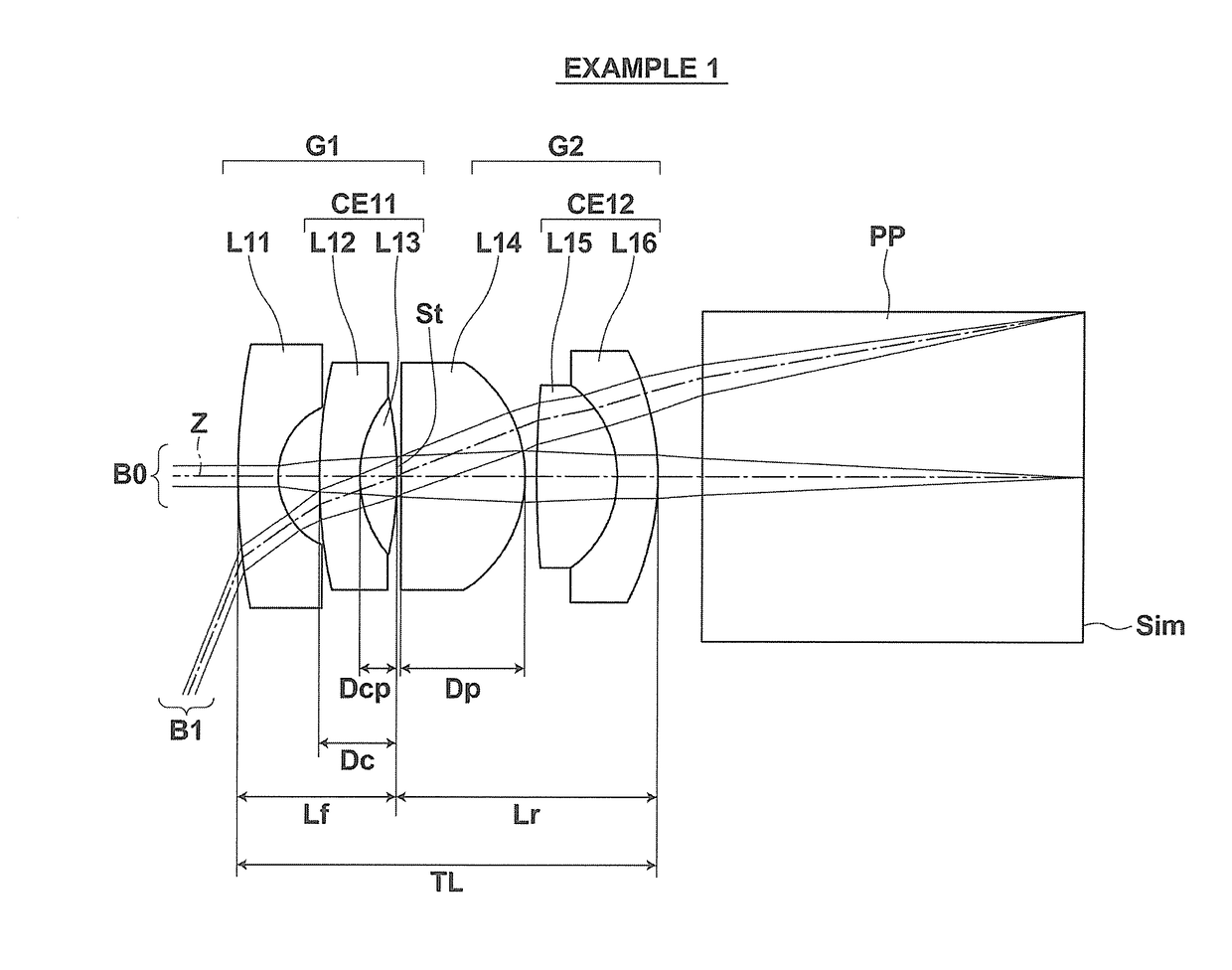

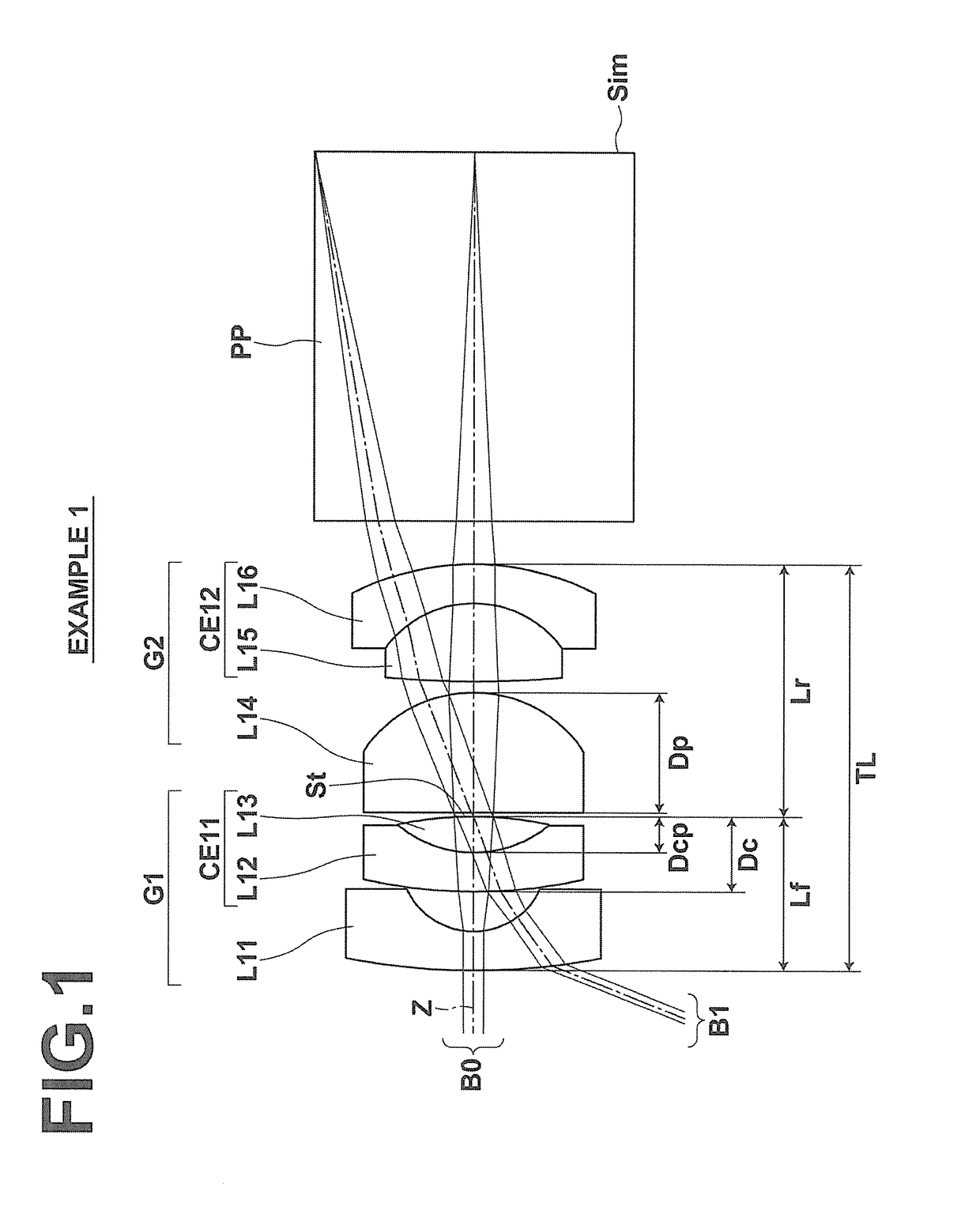

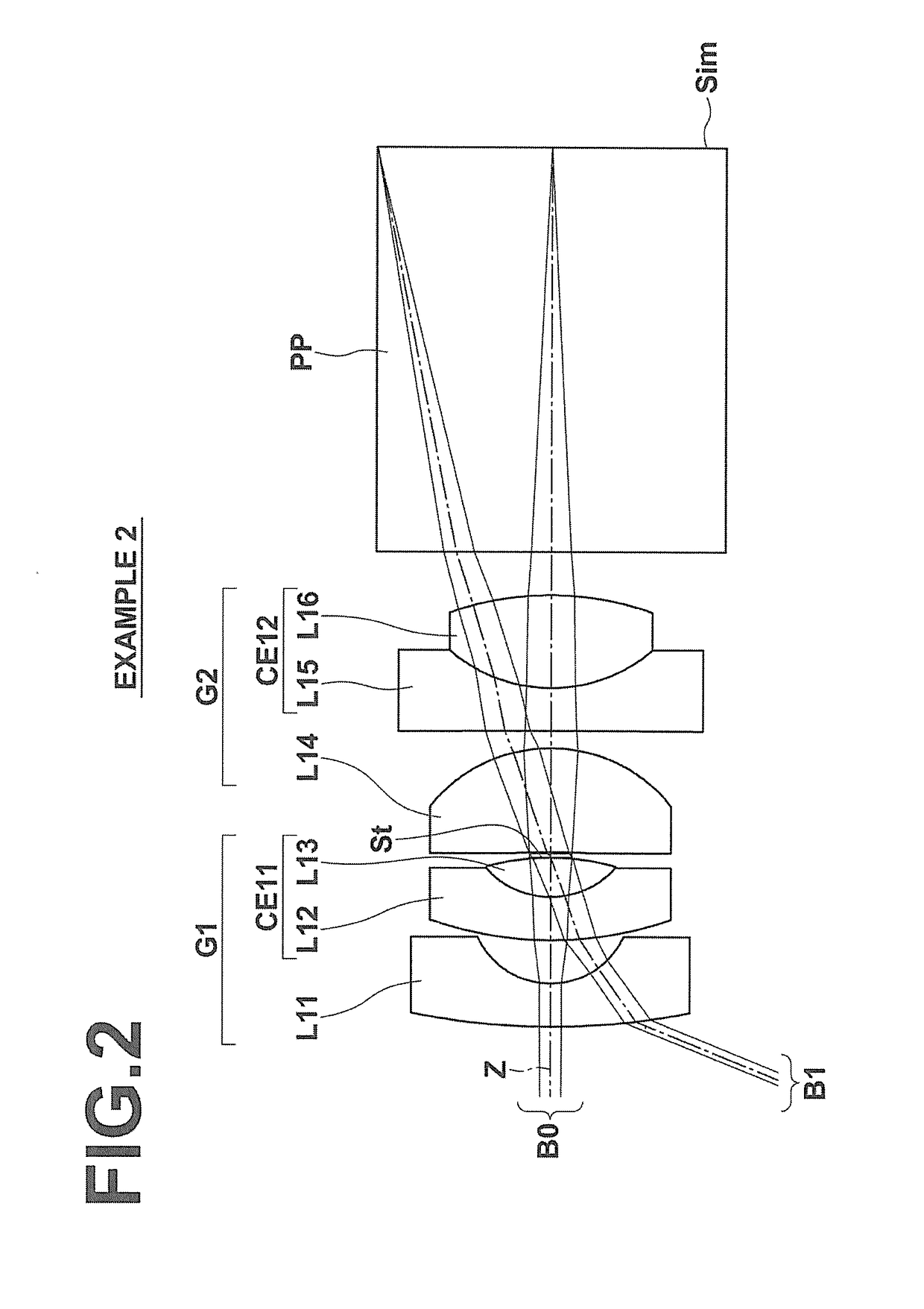

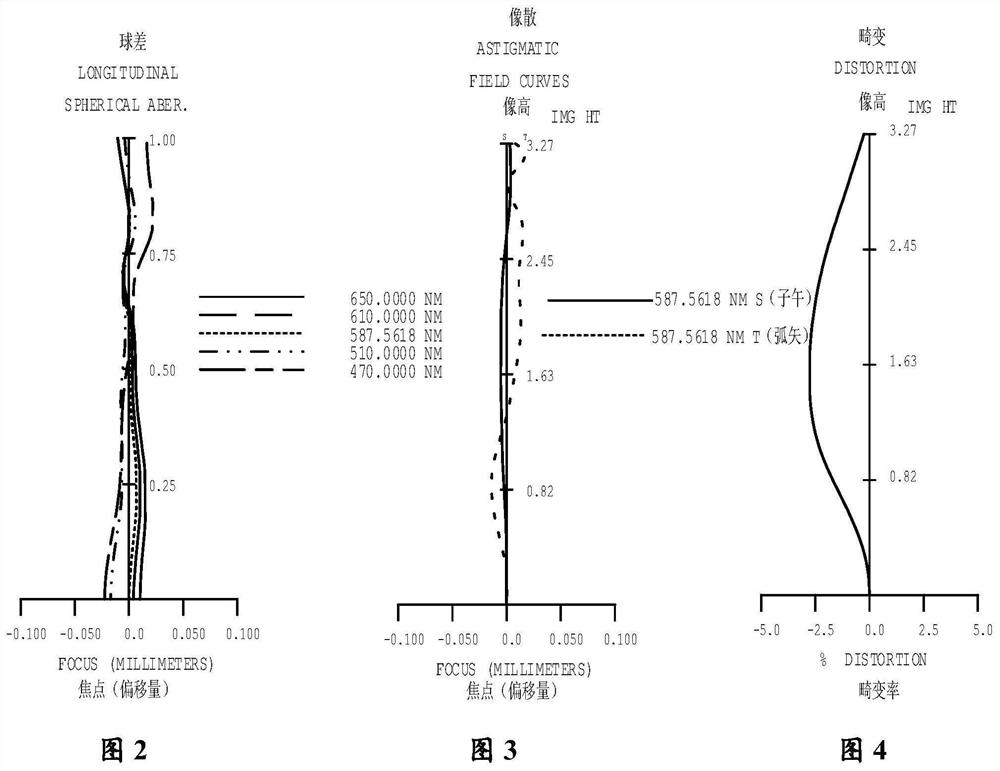

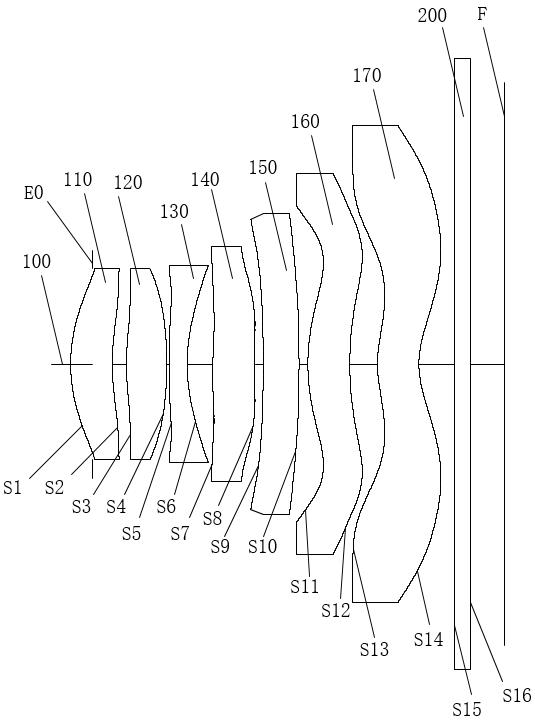

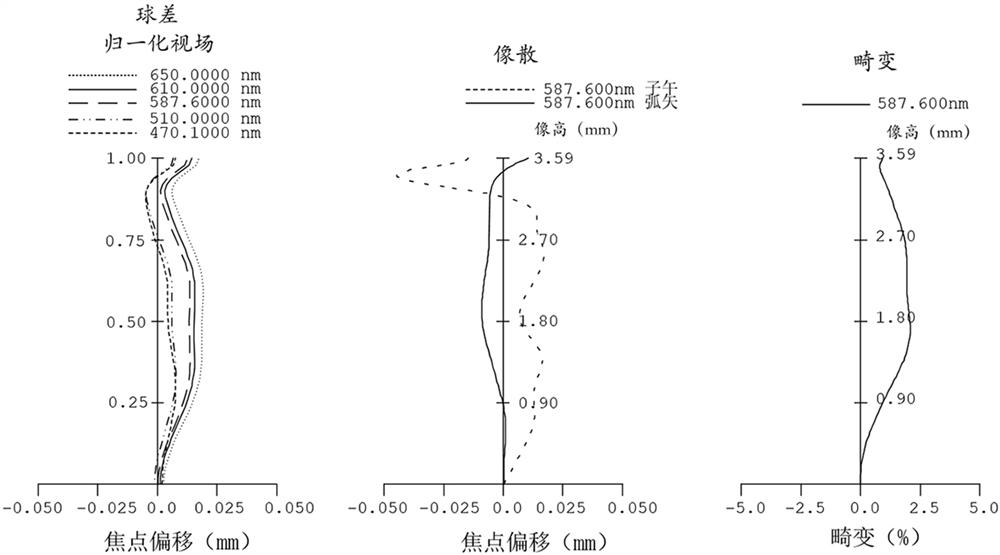

Endoscope objective lens and endoscope

An endoscope objective lens consists essentially of, in order from the object side, a negative first lens group, a stop, and a positive second lens group. At least one of the first lens group and the second lens includes only one cemented lens which is formed by a positive lens and a negative lens cemented together. The entire system includes a positive single lens. The endoscope objective lens satisfies given condition expressions relating to the focal length of the entire system, the center thickness of the positive single lens, the center thickness of the cemented lens, the distance from the most object-side lens surface to the stop, and the distance from the stop to the most image-side lens surface.

Owner:FUJIFILM CORP

Endoscope objective lens and endoscope

ActiveUS9678327B2Reduce the burden onImprovement of entire length of lensTelescopesConditional expressionEndoscope

An endoscope objective lens consists essentially of, in order from the object side, a negative first lens group, a stop, and a positive second lens group. At least one of the first lens group and the second lens includes only one cemented lens which is formed by a positive lens and a negative lens cemented together. The entire system includes a positive single lens. The endoscope objective lens satisfies given condition expressions relating to the focal length of the entire system, the center thickness of the positive single lens, the center thickness of the cemented lens, the distance from the most object-side lens surface to the stop, and the distance from the stop to the most image-side lens surface.

Owner:FUJIFILM CORP

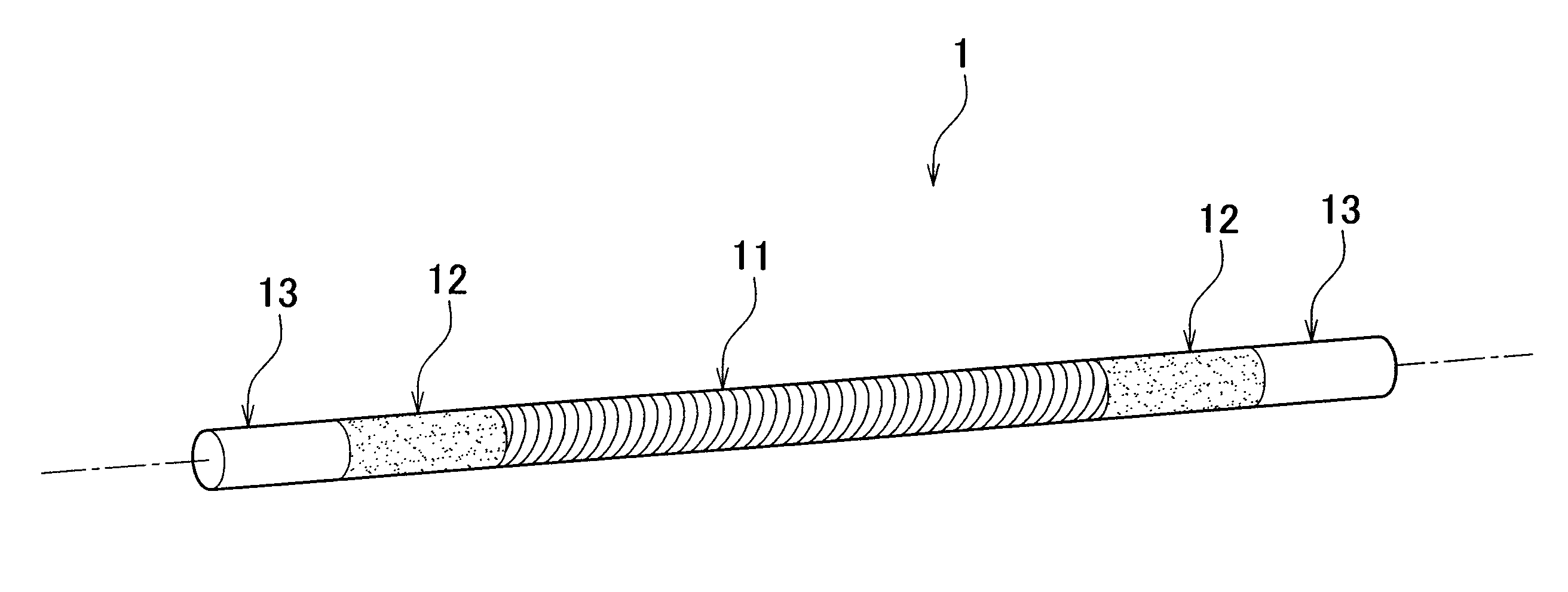

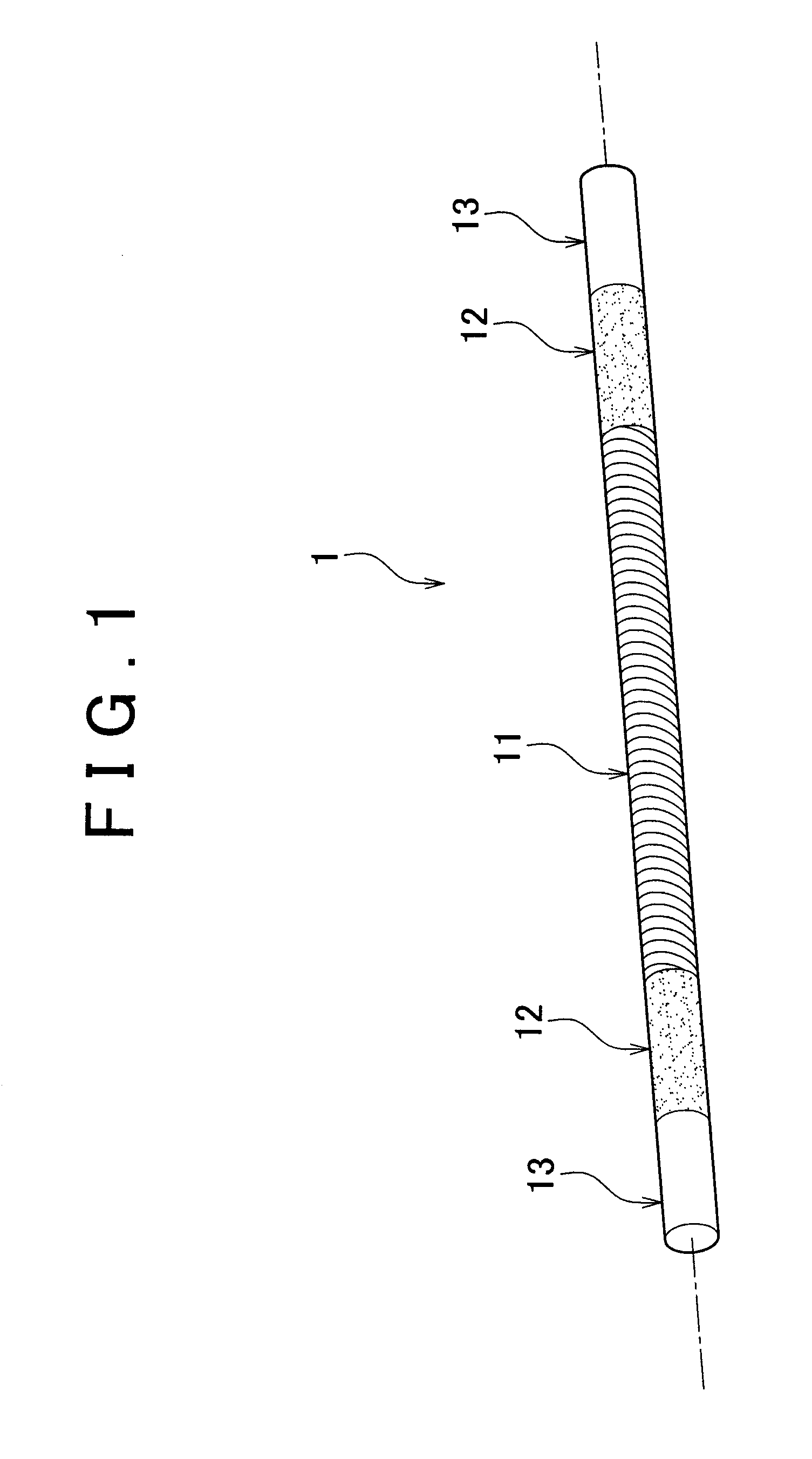

Application roller and manufacturing method of application roller

ActiveUS20120318192A1Reduce coatingIncrease edge thicknessLiquid surface applicatorsLamination ancillary operationsEngineeringMechanical engineering

A manufacturing method of an application roller that applies a coating solution onto a surface of a substrate, wherein the application roller includes a roller body that includes a large diameter portion and small diameter portions coaxially extended from both ends of the large diameter portion, the manufacturing method includes: overlaying a resin layer on at least an outer periphery of each of the small diameter portions; forming a masking portion on the outer periphery of each of the small diameter portions by processing an outer periphery of the resin layer; and forming an application groove portion on an outer periphery of the large diameter portion.

Owner:TOYOTA JIDOSHA KK

Wafer treatment solution for edge-bead removal, edge film hump reduction and resist surface smooth, its apparatus and edge-bead removal method by using the same

ActiveUS9508558B2Improve efficiencyReduce harmDetergent mixture composition preparationPhotomechanical apparatusResistPhotoresist

The present disclosure provides a wafer treatment solution for edge-bead removal, edge film hump reduction and resist surface smooth. The wafer treatment solution includes a solution and a fluorine-containing additive mixed in the solution. The fluorine-containing additive has a following formula (I): Rf—X—(CH2CH2O)m—R1 (I); or a following formula (II):An apparatus and a method by using the wafer treatment solution are also provided herein.

Owner:KE I SHAN

Separating device

InactiveUS6880809B2Trend downLess prone to failureWorkpiece holdersLifting devicesEngineeringMechanical engineering

Owner:ACTUANT OPERATIONS UK LTD

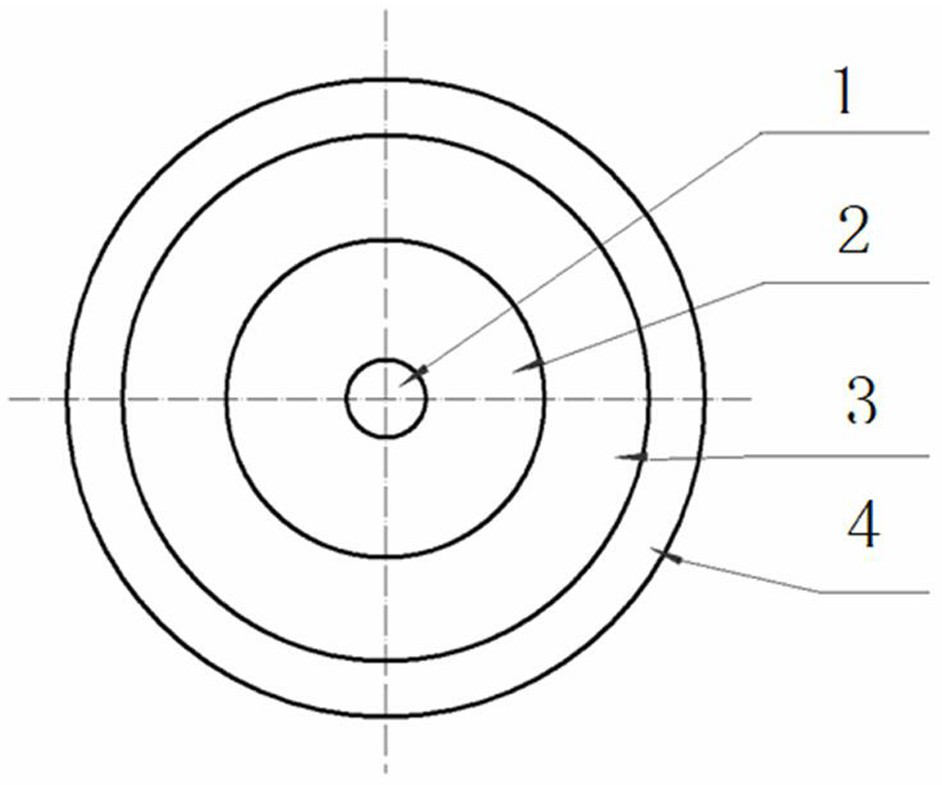

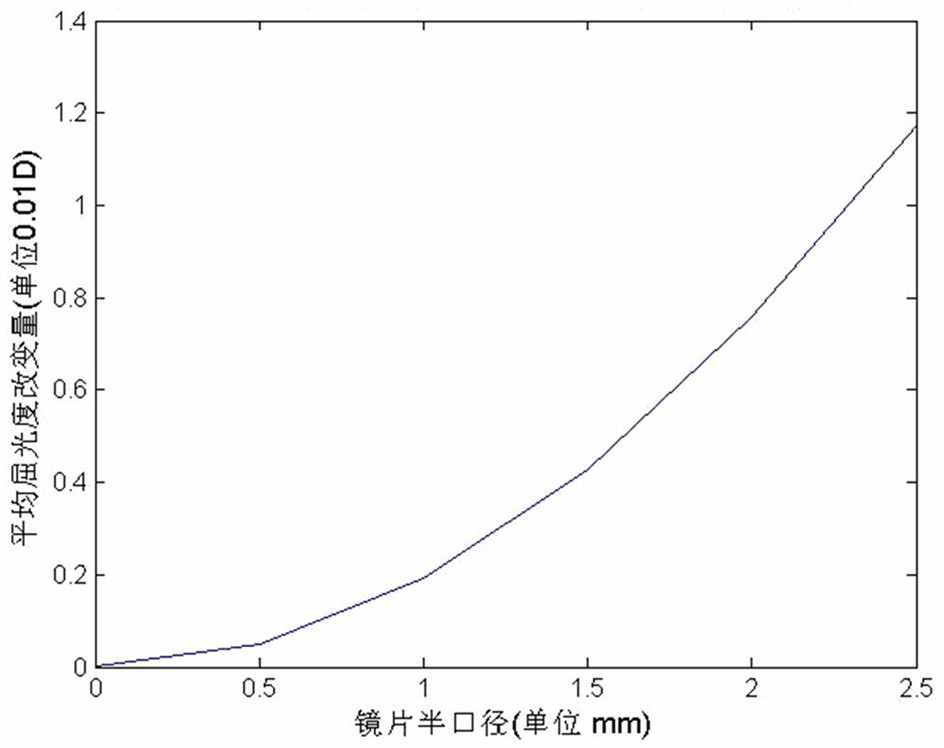

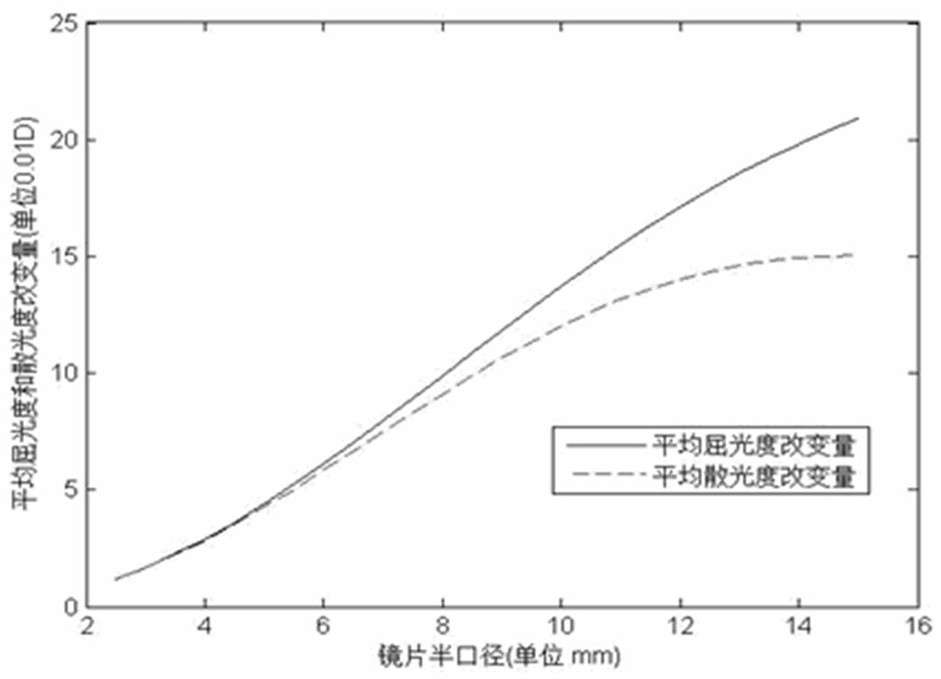

Preparation method of double-sided composite thinned and zooming myopic lens

PendingCN112505945AReduce edge thicknessEliminate astigmatismSpectales/gogglesOptical partsMathematical modelEngineering

The invention relates to a preparation method of a double-sided composite thinned and zooming myopic lens, and belongs to the technical field of optical lens design. According to the invention, the method comprises the following steps: S1, establishing a front surface mathematical model and a rear surface mathematical model in optical software; S2, establishing an evaluation function including theastigmatism optimization value and the lens edge thickness; and S3, inputting structural parameters of the lens blank, and successively optimizing by applying a least square method to obtain data ofthe front surface and the rear surface of the lens. The edge thickness of the lens prepared by the preparation method of the double-sided composite thinned and zooming myopic lens is reduced by 20%-30% compared with that of a spherical surface; the zoom range from the optical center to the edge degree not only reaches + / -4.00 D, but zooming can be performed according to an optometry prescription when the diameter of the lens is 10-40mm, and astigmatism is basically eliminated when the diameter of the lens is 50mm.

Owner:魏炳松 +1

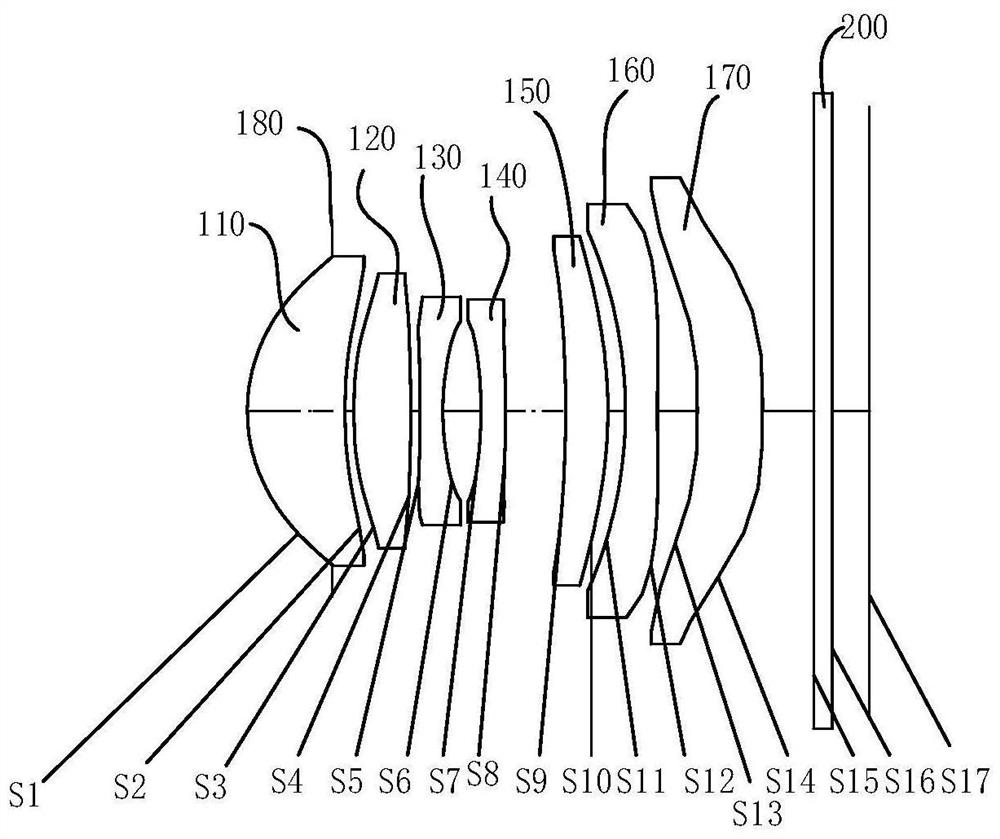

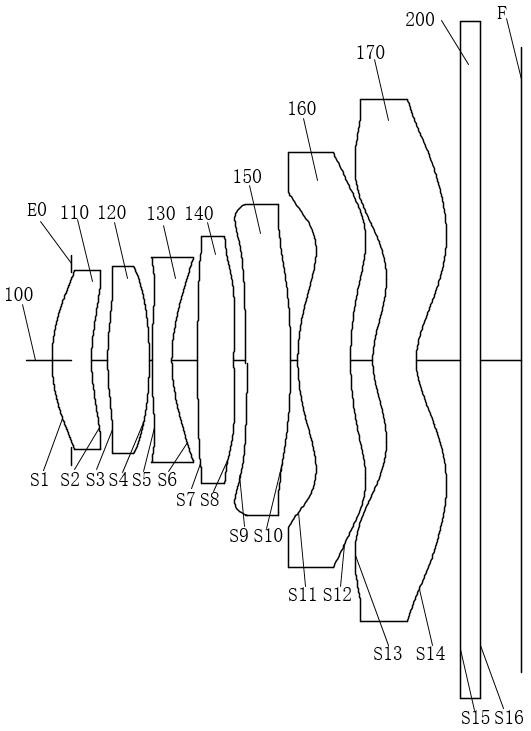

Optical lens group, camera module and terminal

PendingCN111897097AReduce thicknessReduce the maximum diameterOptical elementsCamera lensOphthalmology

The invention discloses an optical lens group, a camera module and a terminal. The optical lens group comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens, a sixth lens anda seventh lens which are sequentially arranged from an object plane to an image plane along an optical axis, wherein the first lens has positive refractive power, the object side surface, near the optical axis, of the first lens is a convex surface, the second lens, the third lens, the fourth lens, the fifth lens, the sixth lens and the seventh lens respectively have refractive power, the maximumeffective diameter of the image side surface of the seventh lens is Y7[2], the distance between the object side surface of the first lens and the imaging surface of the system at the optical axis isTTL, the thickness of the optical effective diameter edge of the object side surface of the seventh lens is ET[7], the focal length of the optical lens group is f, and Y7[2], TTL, ET[7] and f satisfythe following conditional expression: (Y7[2]*TTL) / (ET[7]*f) is more than or equal to 3 and less than or equal to 8. Through the arrangement, the long-focus characteristic of the optical lens group andthe overall thickness of the optical camera lens can be balanced, and the maximum diameter of the optical camera lens is reduced while the molding yield of the seventh lens is ensured.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

Control method for reducing edge thickness of galvanized plate with super-thick zinc layer

PendingCN113789492AReduce thicknessReduce rolling forceHot-dipping/immersion processesFurnace typesEngineeringAir knife

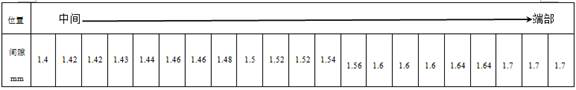

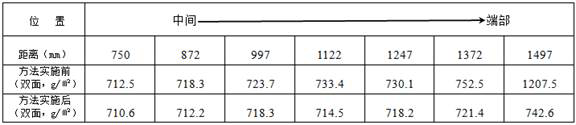

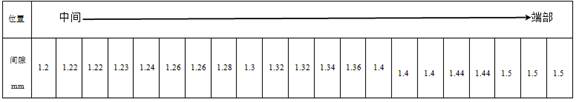

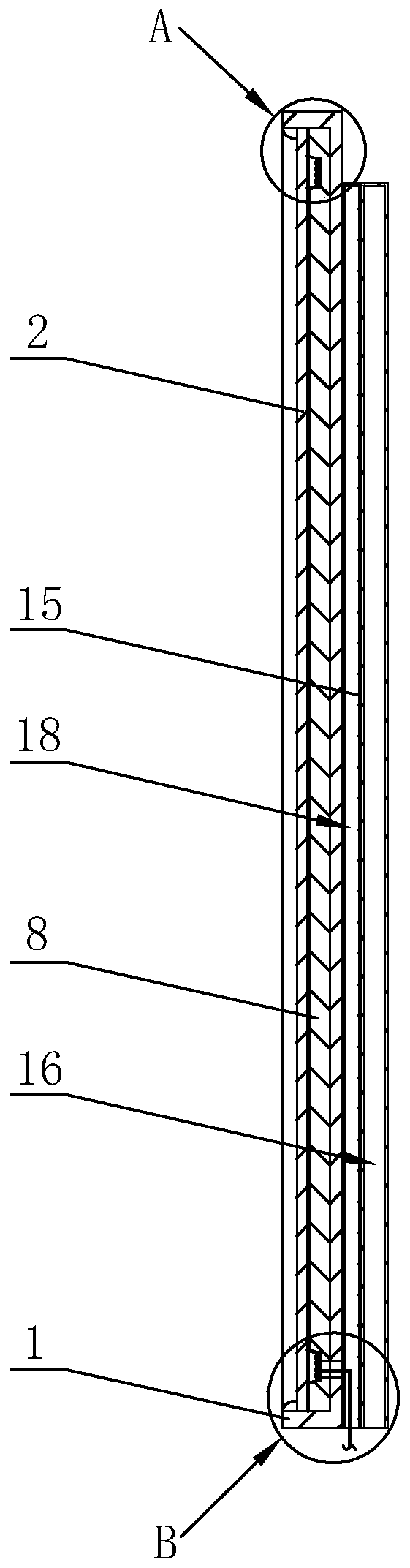

The invention relates to a control method for reducing the edge thickness of a galvanized plate with an ultra-thick zinc layer, and belongs to the technical field of production of ultra-thick zinc layer products in the metallurgical industry. According to the technical scheme, control is conducted according to the following steps that (1) a hot-rolled plate serves as a base plate, and the thickness of the zinc layer is larger than or equal to 500 g / m<2>; (2) the convexity of the hot-rolled plate adopts positive convexity, specifically, the value of the positive convexity is 40-70 microns; (3) it is ensured that the end part is smooth and burr-free after the hot-rolled plate is trimmed; (4) the annealing temperature of the hot-rolled plate is 670-690 DEG C, and the temperature of the hot-rolled plate entering a zinc pot is 460-465 DEG C; and (5) on the basis of 1.2-1.4 mm in the middle, an air knife gap is gradually increased towards the two ends by the increment of 0.02-0.3 mm till the air knife gap is increased to 1.5-1.7 mm. The control method has the beneficial effects that the edge thickness can be reduced, the thickness difference of the galvanized plate is reduced, and the defects such as waves are avoided.

Owner:HEBEI IRON AND STEEL +1

Dressing mirror

InactiveCN110215093AReduce edge thicknessReduce thicknessPicture framesLighting elementsSand blastingOptoelectronics

The invention discloses a dressing mirror, and relates to the technical field of decorative design. The dressing mirror comprises a mirror frame, and a mirror is arranged in an opening in one side ofthe mirror frame in a clamping manner; the mirror comprises a glass layer arranged in the opening of the mirror frame in a clamping manner, and a plated layer coats the side face, close to the bottomof the opening of the mirror frame, of the glass layer; and the edge of the mirror forms a light-pervious ring through removal of the plated layer, a sand blasting face is arranged at the position, with the light-pervious ring, of the surface of the glass layer, and a light-emitting part is arranged in the mirror frame along the light-pervious ring. Aiming at the problem that the width of a frameof a light-supplementing mirror is large in the prior art, the dressing mirror adopts the structure that the light-emitting part is arranged in the mirror frame, so that the thickness of the edge of the mirror frame is greatly reduced, the imaging area is improved, the view field of customers is increased, and further, the satisfaction degree of the cloths try-on experience of the customers is improved.

Owner:上海臻旺装饰设计工程有限公司

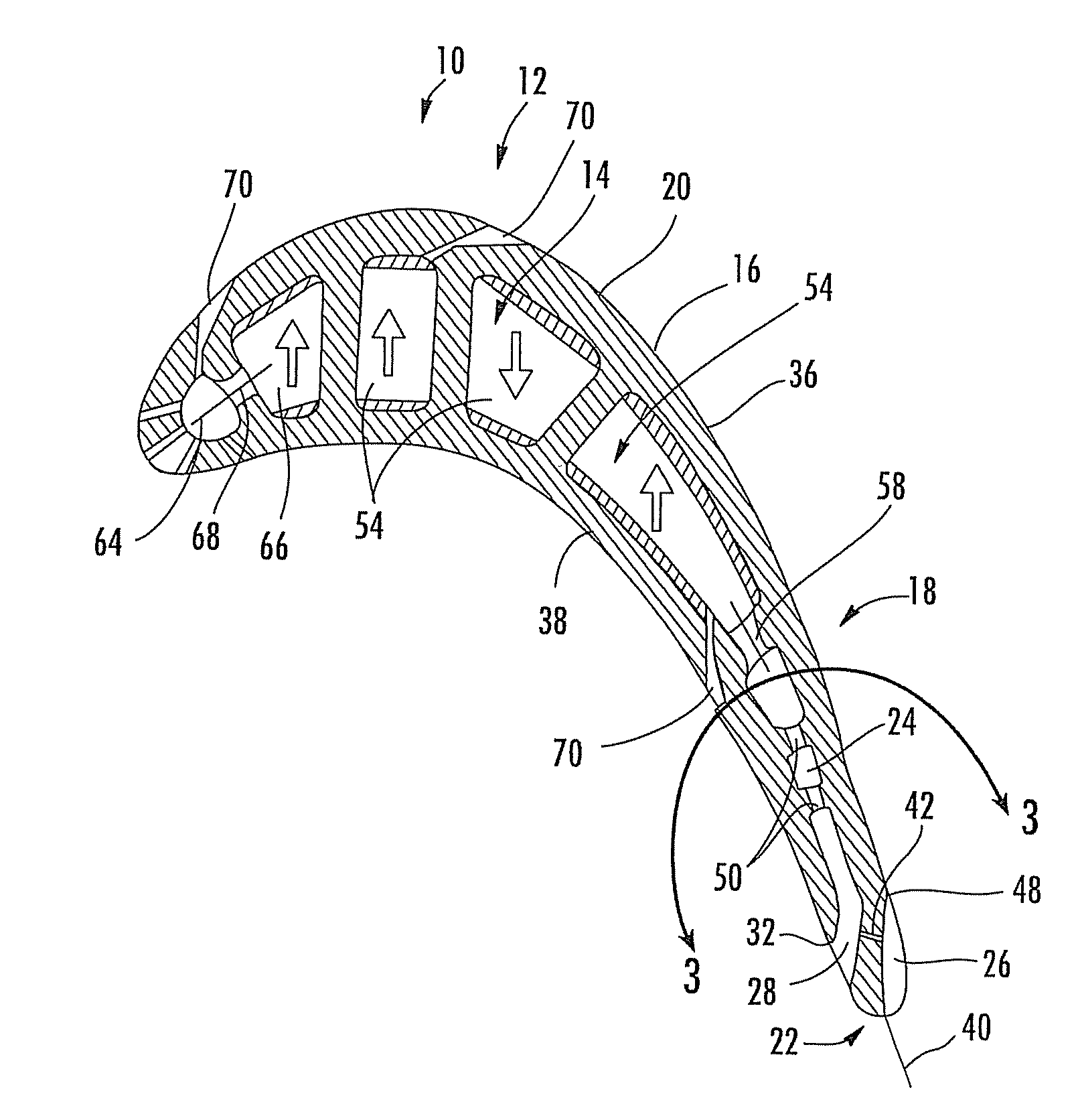

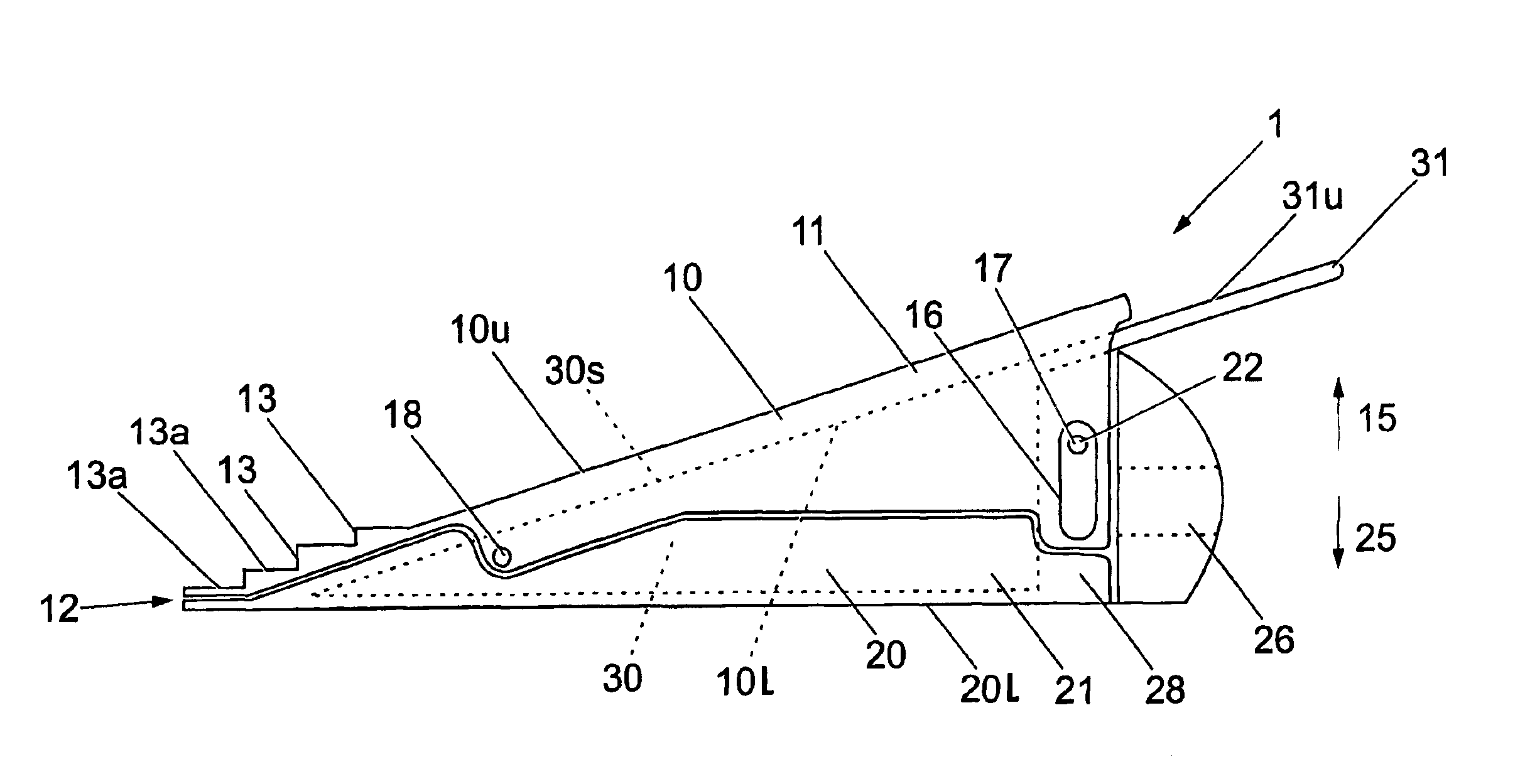

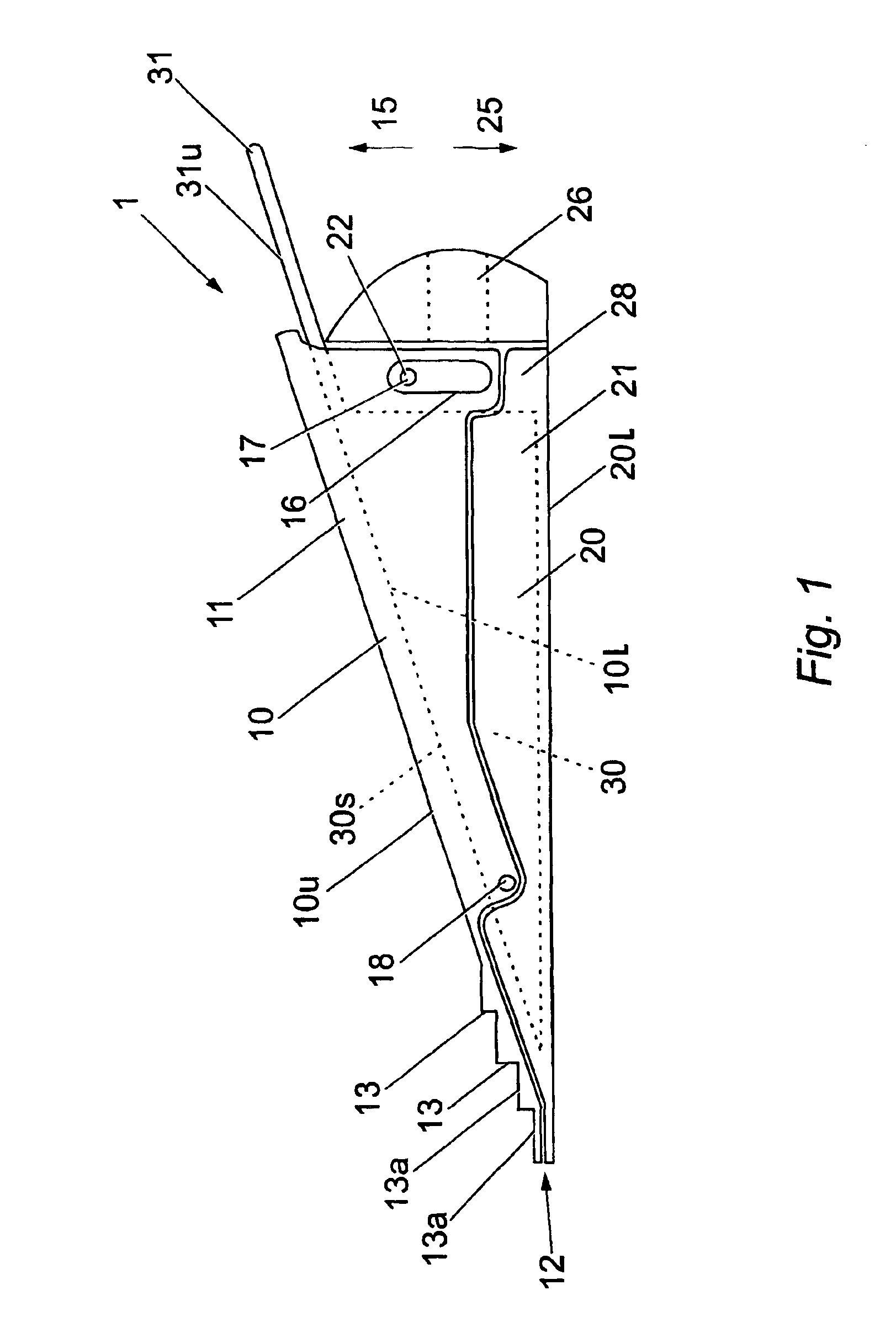

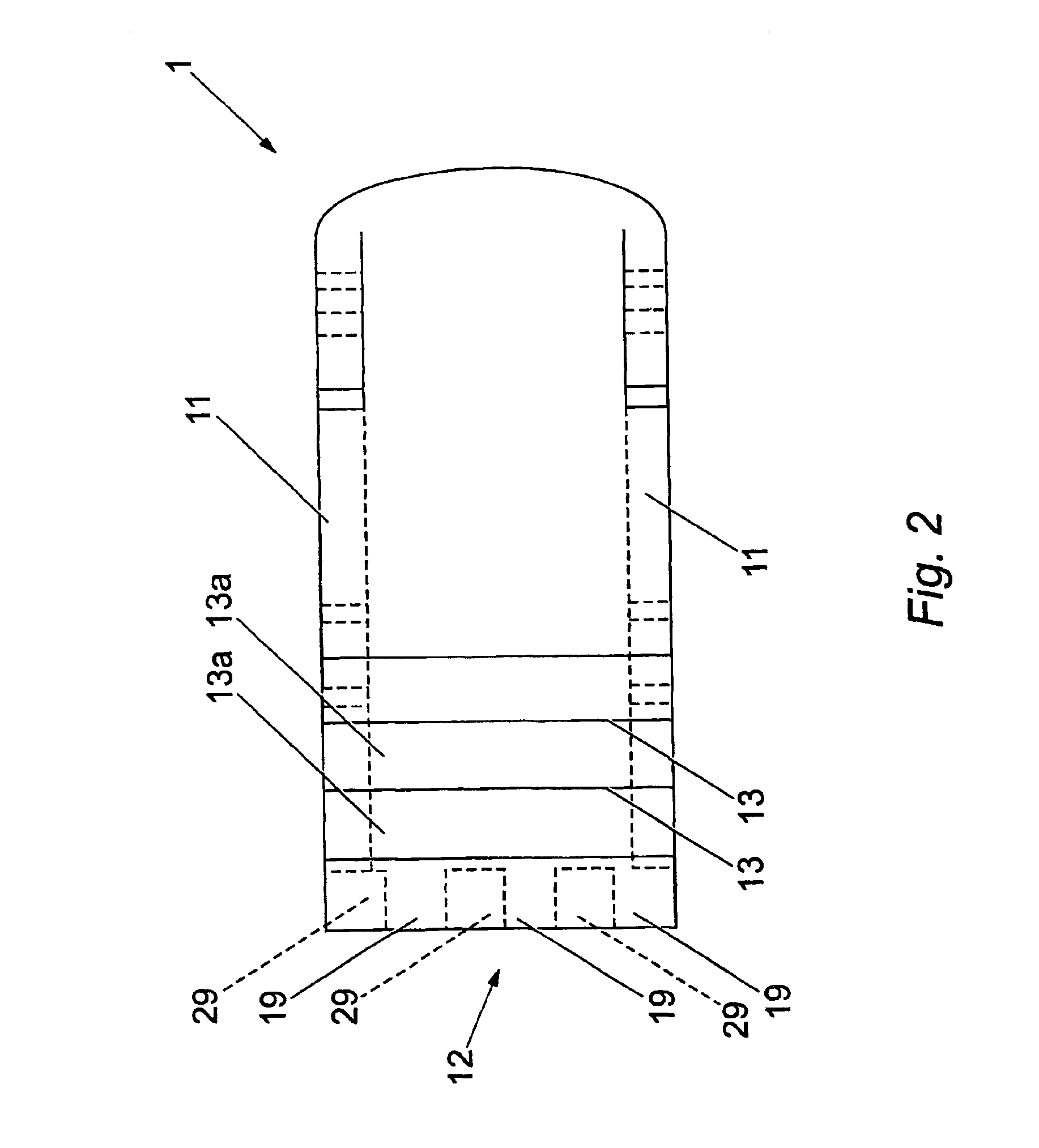

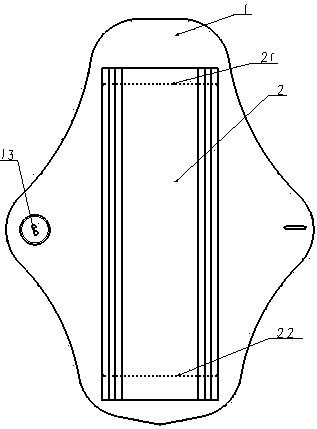

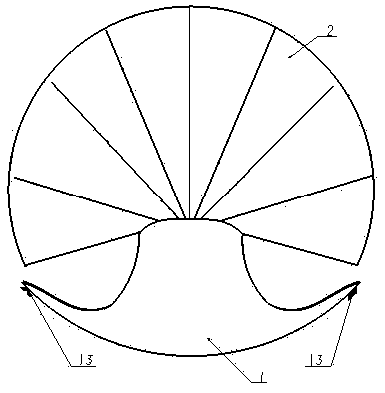

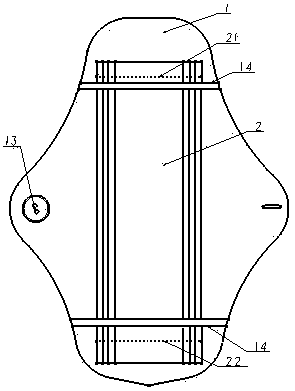

Absorbent article

The invention relates to the technical field of hygienic products, in particular to an absorbent article. The absorbent article comprises an absorbent body and a wearing part; the absorbent article ischaracterized in that the absorbent body is arranged on the wearing part; the wearing part can be attached to the crotch region of underpants conveniently or can be made into a shorts type; and the absorbent body is formed by folding an absorbent sheet in the longitudinal direction, and the absorbent body is fixed in a folded shape by pressing or sewing the vicinity of at least at the front end and the rear end of the absorbent sheet. The absorbent article can be circularly cleaned and utilized, can be opened and stored in a fan shape, and is environment-friendly and more sanitary and safer;a flow blocking piece is additionally arranged, so that the side leakage prevention effect and the back leakage prevention effect are better; and the attractiveness degree is increased by virtue of the embroidery edge, and the material is more ideal.

Owner:李丽

A kind of ultra-thick coating hot-dip galvanized steel strip for corrugated pipe of underground pipe gallery and production method thereof

ActiveCN110684929BReduce the temperatureReduce core heatHot-dipping/immersion processesChemical compositionStrip steel

The invention discloses an ultra-thick coated hot-dip galvanized steel strip for corrugated pipes of an underground pipe gallery and a production method thereof. The chemical composition and mass percentage of the hot-dip galvanized steel strip are: C: 0.045-0.065%, Mn : 0.15~0.25%, S≤0.020%, P≤0.020%, Si≤0.03%, Als≥0.020%, the rest is iron and unavoidable impurities; the production methods include converter smelting, LF refining, continuous casting, thermal Rolling, cold rolling and galvanizing processes. The invention guarantees the appropriate mechanical properties of the steel strip through reasonable composition design and hot rolling and galvanizing annealing process design; and adopts segmental control measures for reducing the height of the air knife, increasing the distance between the knife lip and the strip steel, and the opening degree of the air knife knife lip , suppressing the generation of zinc flow marks and edge thickness defects, meeting the needs of the underground pipe gallery industry for ultra-thick coated hot-dip galvanized steel strips, and having significant economic benefits.

Owner:TANGSHAN IRON & STEEL GROUP +1

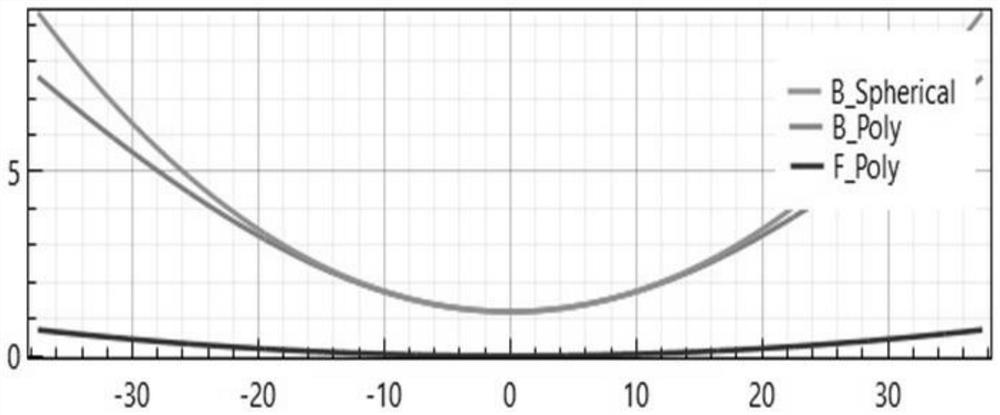

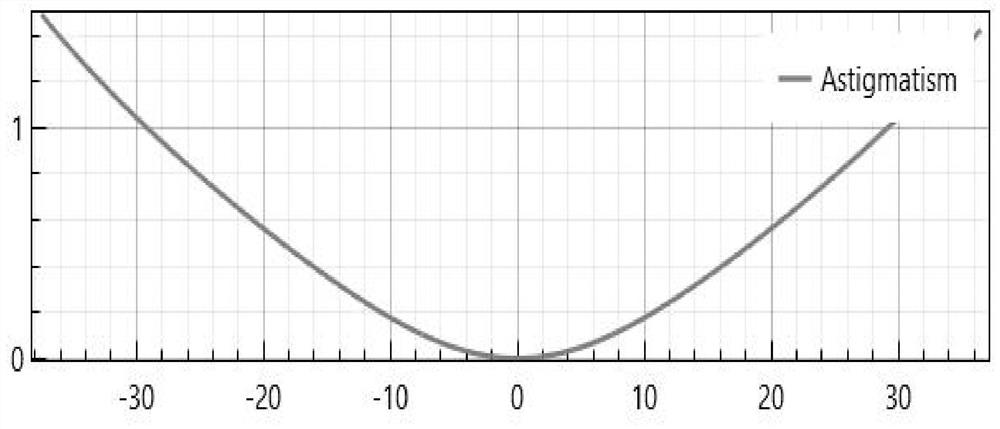

Optimally designed aspheric myopia lens and preparation mold thereof

ActiveCN113419358AWill not affect wearing comfortReduce off-axis aberrationsOptical partsOphthalmologyImaging quality

The invention discloses an optimally designed aspheric myopia lens and a preparation mold thereof. A spectacle lens body is divided into four areas, namely a central luminosity stable area with stable diopter change, an off-axis aberration correction area which adopts focal power compensation and controls an astigmatism value and an average diopter value, an astigmatism control area which reduces the astigmatism value as much as possible, and a processing control area which effectively controls stable change of rise and reduces edge thickness. The imaging quality of the aspheric myopia lens provided by the invention is superior to that of a myopia lens with the same luminosity in the prior art, and the aspheric myopia lens can improve the wearing comfort and reduce the influence that the actual wearing effect deviates from the theoretical design caused by the inclination angle of a spectacle frame, the wearing position of the frame spectacles and the bad habits of a wearer according to the use characteristics of the frame spectacles; meanwhile, the spectacle lens can be manufactured in batches through a mold, is convenient to process, reduces the cost, and is beneficial to further popularization and application of the aspherical lens.

Owner:SUZHOU MASON OPTICAL CO LTD +1

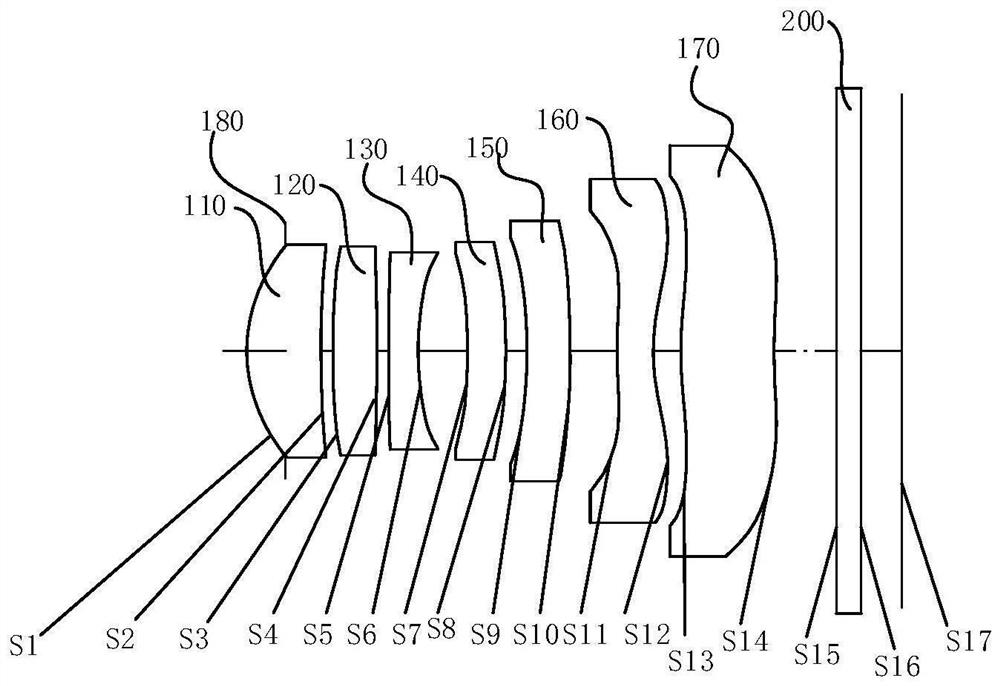

Optical lens group, camera module and electronic equipment

The invention discloses an optical lens group, a camera module and electronic equipment, and the optical lens group comprises a first lens which has positive focal power, wherein the object side surface of the first lens is a convex surface near an optical axis; a second lens which has focal power, wherein the object side surface of the second lens is a convex surface near the optical axis; a third lens which has focal power; a fourth lens which has focal power, wherein the object side surface of the fourth lens is a convex surface near the optical axis, and the image side surface of the fourth lens is a concave surface near the optical axis; a fifth lens which has positive focal power, wherein the object side surface of the fifth lens is a concave surface near the optical axis, and the image side surface of the fifth lens is a convex surface near the optical axis; a sixth lens which has positive focal power, wherein the object side surface of the sixth lens is a convex surface near the optical axis; and a seventh lens which has negative focal power, wherein the image side surface of the seventh lens is a concave surface near the optical axis. By designing the optical lens group composed of seven lenses, the distribution of the lenses in the space can be reasonably distributed to realize the compression of the total length of the lens group, so that the design requirements of ultra-thinness and high resolution are met.

Owner:JIANGXI JINGCHAO OPTICAL CO LTD

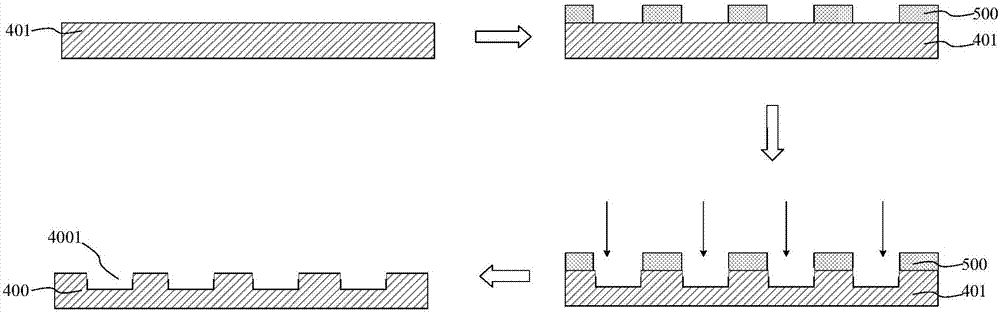

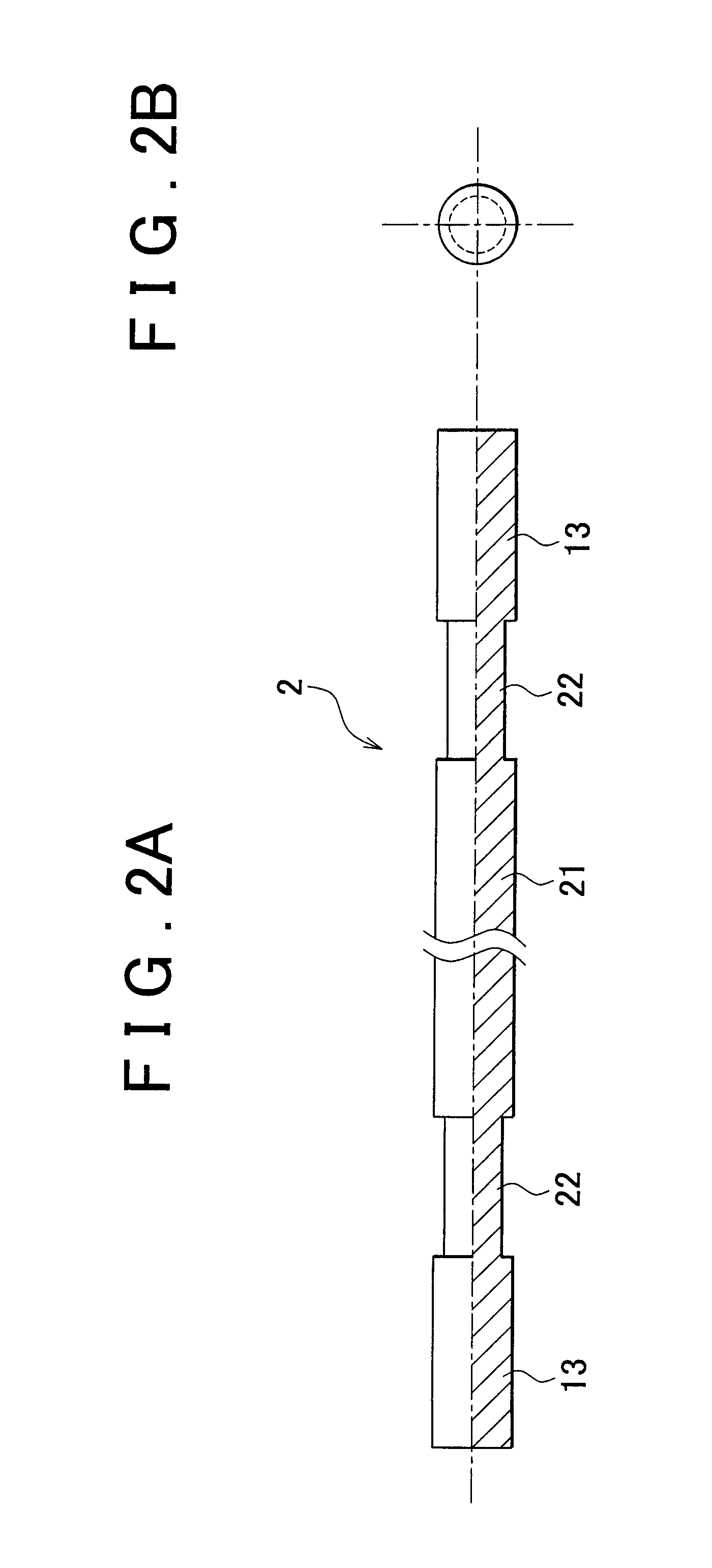

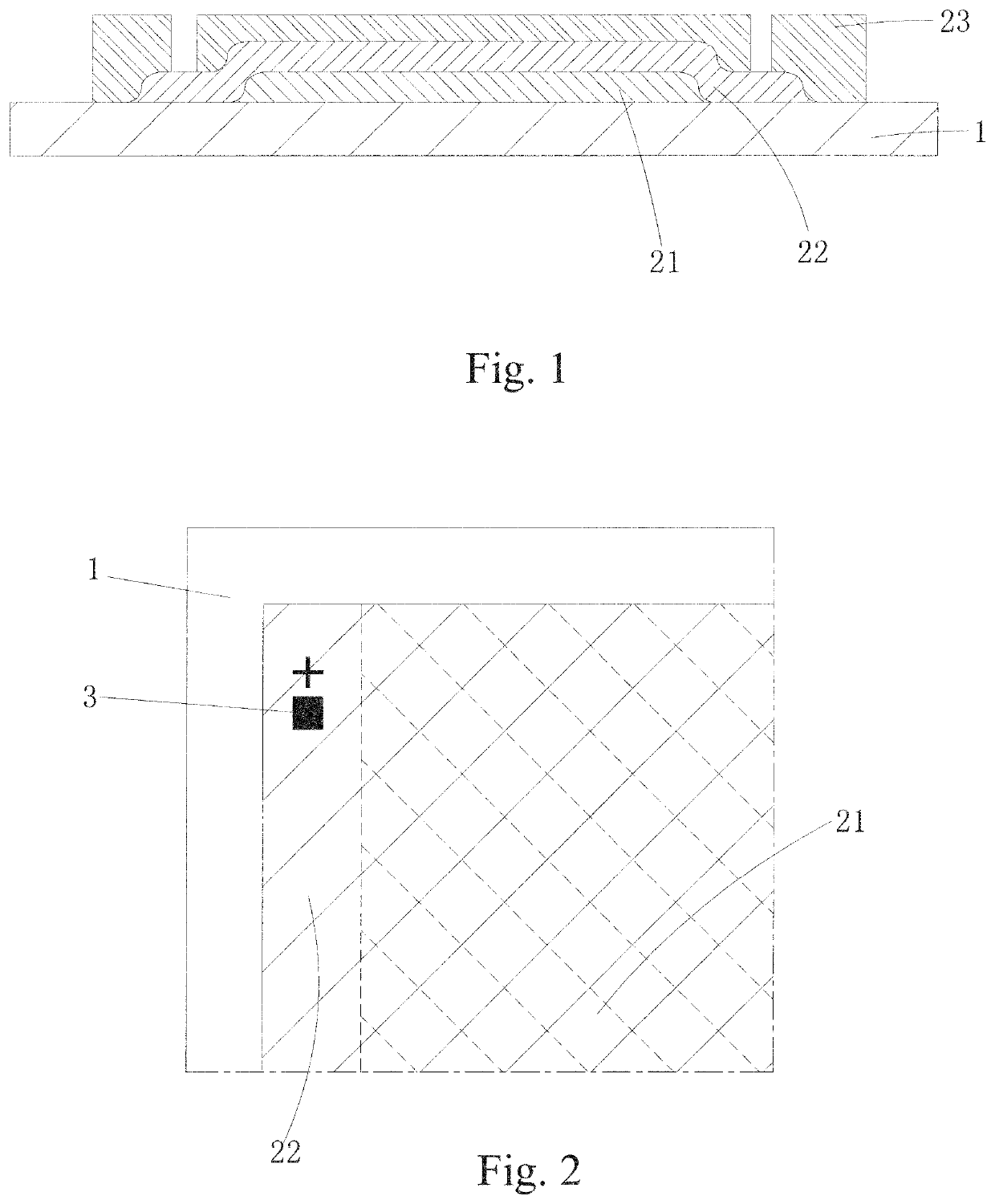

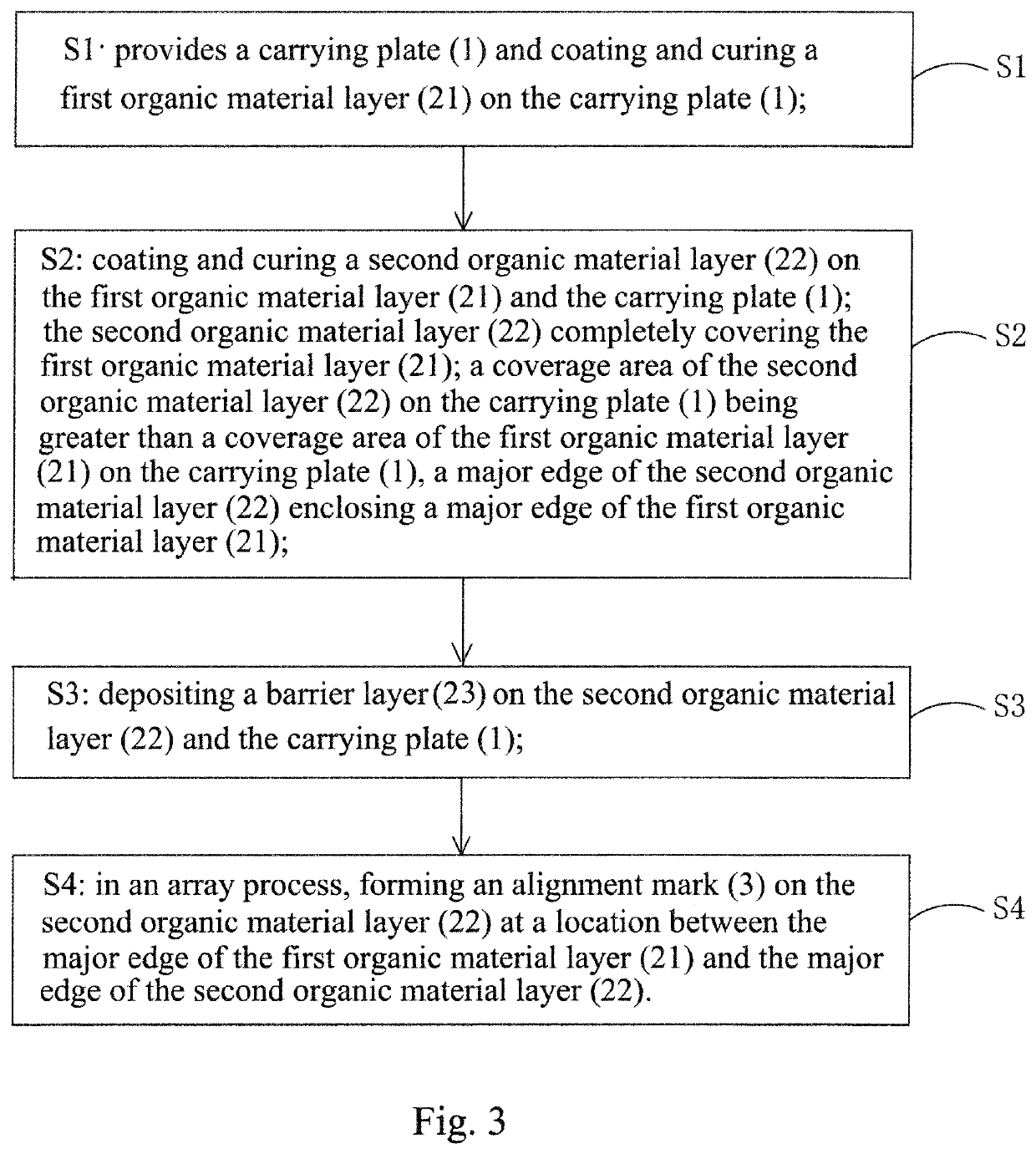

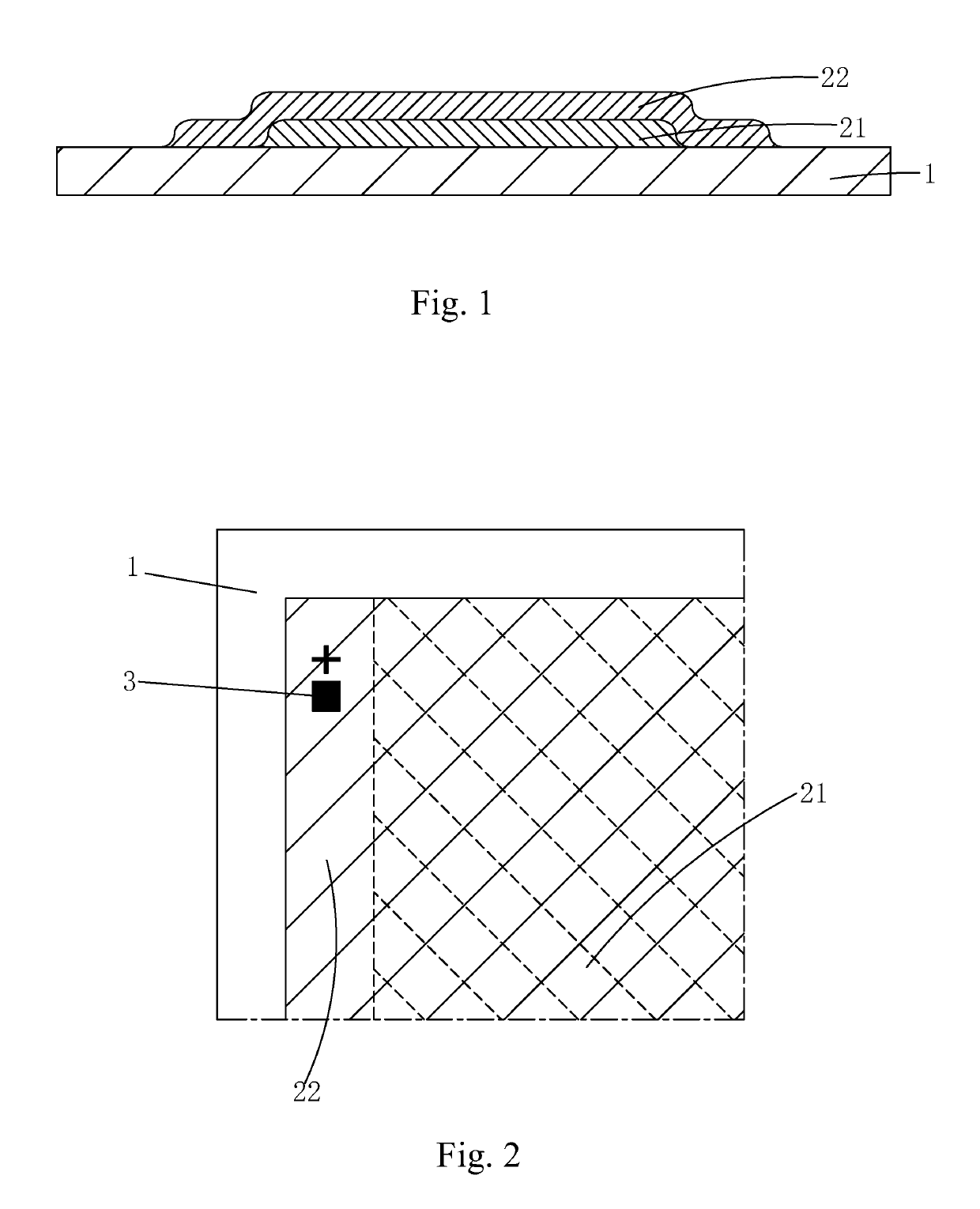

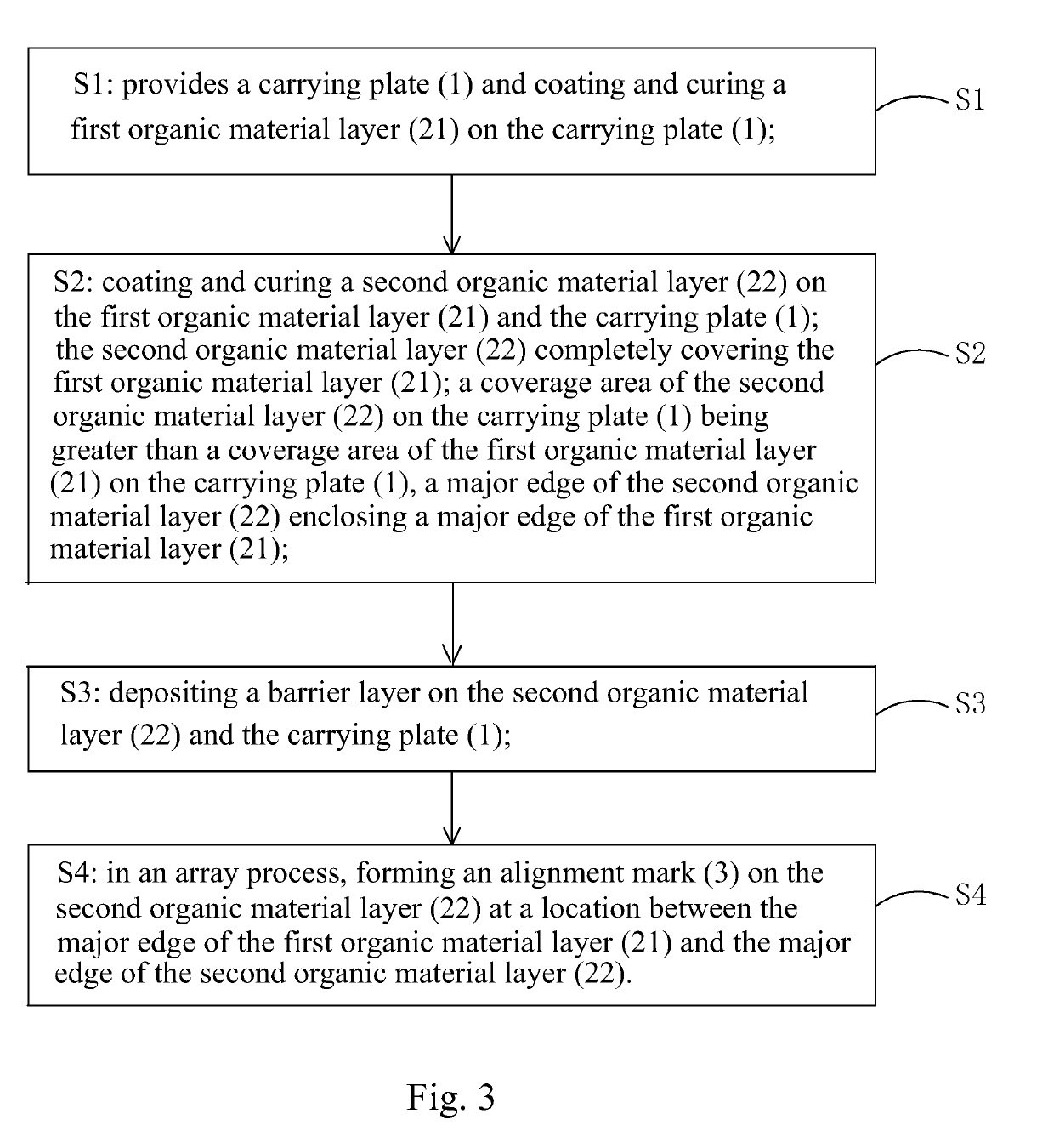

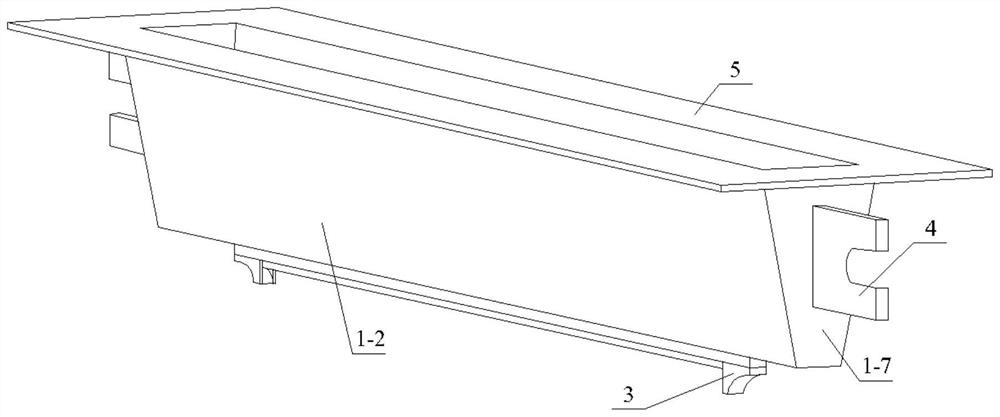

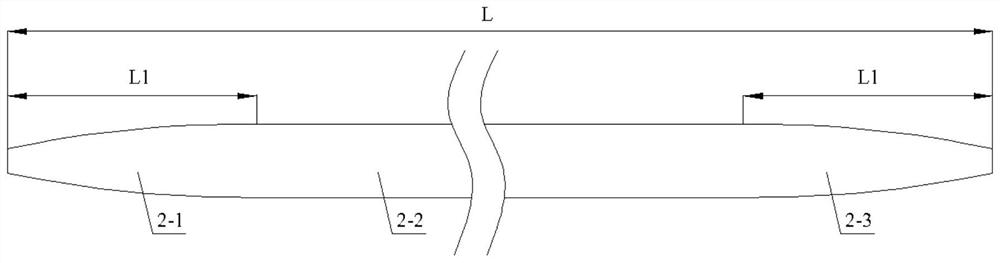

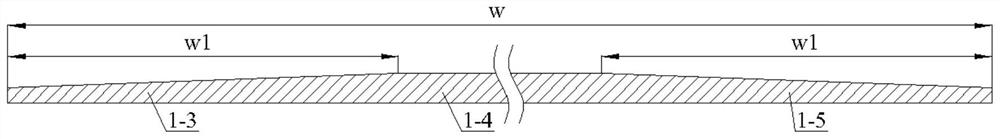

Flexible substrate and manufacturing method thereof

ActiveUS10586936B2Increase ratingsImprove accuracyFinal product manufactureSolid-state devicesStructural engineeringMaterials science

The present invention provides a flexible substrate and a manufacturing method thereof. The flexible substrate is divided into a first organic material layer (21) and a second organic material layer (22). A coverage area of the second organic material layer (22) on a carrying plate (1) is greater than a coverage area of the first organic material layer (21) on the carrying plate (1) and a major, long edge of the second organic material layer (22) encloses a major, long edge of the first organic material layer (21) so as to help reduce the thickness of an edge of the flexible substrate and prevent etching residue at an edge, reduce the coverage area of the organic materials on the carrying plate, and reduce warpage of the flexible substrate. Further, an alignment mark (3) is formed on the second organic material layer (22) at a location between the major, long edge of the first organic material layer (21) and the major, long edge of the second organic material layer (22) to ensure alignment accuracy in subsequent processes, such as vapor deposition. Further, since there is only one layer of organic material at the site of alignment mark (3), light transmission rate is increased and the rate of successful alignment is enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A method for improving the uniformity of thin film deposition

ActiveCN107881486BIncrease the adsorption areaIncrease gas adsorption capacityChemical vapor deposition coatingSurface structureElectrical and Electronics engineering

The invention provides a method for improving the deposition uniformity of thin films. The method comprises the following steps that a plurality of pieces of wafers are borne by using a wafer cassette; the wafer cassette is provided with a head part and a tail part, and the multiple pieces of wafers are arranged between the head part and the tail part of the wafer cassette; blocking and controlling sheets are arranged between the multiple pieces of wafers and the head part of the wafer cassette as well as / or the multiple pieces of wafers and the tail part of the wafer cassette; and the wafercassette bearing the wafers and the blocking and controlling sheets is placed in a reaction furnace tube and subjected to thin film deposition, wherein the blocking and controlling sheets have an uneven surface structure. According to the method for improving the deposition uniformity of the thin films, the blocking and controlling sheets with the uneven surface structure are guided in and replace even blocking and controlling sheets in the prior art, the gas adsorption capacity is improved by increasing the adsorption area of the blocking and controlling sheets, and the edge thickness of a product adjacent to the blocking and controlling sheets can be reduced effectively, thus the film thickness uniformity of a chip can be improved effectively, and a curve of the yield loss of the edge of the wafer cassette position is smoothed to improve the product yield.

Owner:CHANGXIN MEMORY TECH INC

Flexible substrate and manufacturing method thereof

ActiveUS20190157583A1Reduce edge thicknessImprove reflectivityFinal product manufactureSolid-state devicesGas phaseEngineering

The present invention provides a flexible substrate and a manufacturing method thereof. The flexible substrate is divided into a first organic material layer (21) and a second organic material layer (22). A coverage area of the second organic material layer (22) on a carrying plate (1) is greater than a coverage area of the first organic material layer (21) on the carrying plate (1) and a major, long edge of the second organic material layer (22) encloses a major, long edge of the first organic material layer (21) so as to help reduce the thickness of an edge of the flexible substrate and prevent etching residue at an edge, reduce the coverage area of the organic materials on the carrying plate, and reduce warpage of the flexible substrate. Further, an alignment mark (3) is formed on the second organic material layer (22) at a location between the major, long edge of the first organic material layer (21) and the major, long edge of the second organic material layer (22) to ensure alignment accuracy in subsequent processes, such as vapor deposition. Further, since there is only one layer of organic material at the site of alignment mark (3), light transmission rate is increased and the rate of successful alignment is enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

A u-shaped groove platinum-rhodium alloy bushing plate

ActiveCN110590132BReduce edge thicknessEffective Width Scale IncreaseGlass forming apparatusPlatinumRuthenium

The invention discloses a U-shaped groove platinum-rhodium alloy leakage plate, which belongs to the technical field of flexible glass forming equipment. The platinum-rhodium alloy leakage plate includes a tank body, and the bottom plate of the tank body is provided with slits for passing glass liquid. The length direction is the same as the length direction of the tank body. The key point is that the slits are divided into sequentially connected first width gradient slits, middle equal width slits, and second width gradient slits from one end to the other end along the length direction. The widths of the width gradient slit and the second width gradient slit gradually decrease from one end close to the middle equal width slit to the other end. The slit with a wide middle and narrow ends can effectively reduce the thickness of the edge of the glass ribbon, increase the effective width ratio of the glass, and make the appearance of the glass plate more even.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com