A u-shaped groove platinum-rhodium alloy bushing plate

A platinum-rhodium alloy and U-shaped groove technology, which is applied in the direction of manufacturing tools, glass forming, glass manufacturing equipment, etc., can solve the problems of process limitations, low glass effective width ratio, and inability to continue production, etc., to achieve an increase in the effective width ratio , Prevent the phenomenon of glass panting, and prevent the effect of high middle and low ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

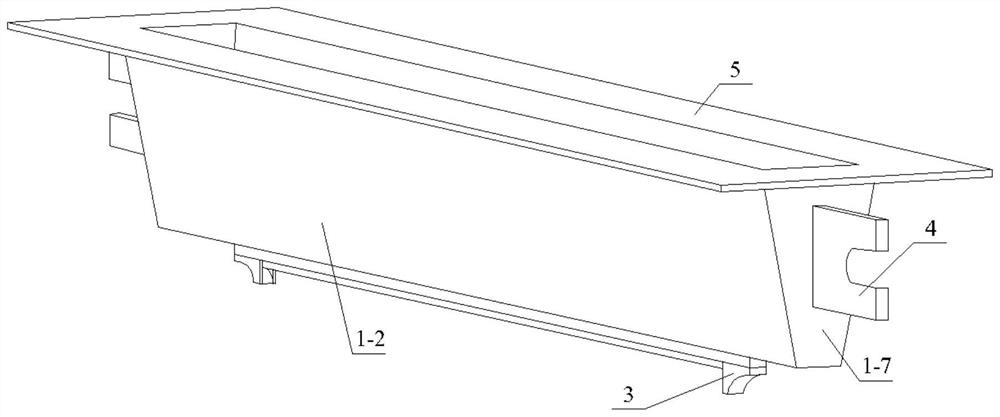

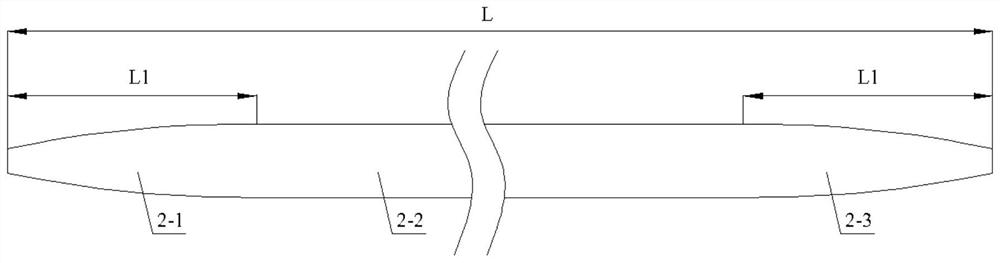

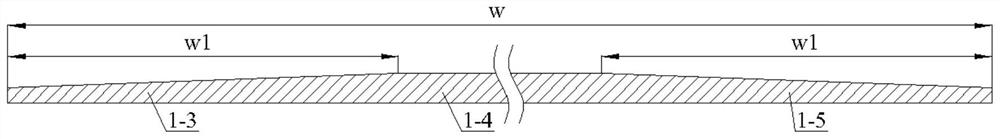

[0031] Specific examples, such as Figure 1 to Figure 8 As shown, a U-shaped groove platinum-rhodium alloy bushing plate includes a tank body 1, and the bottom plate 1-1 of the tank body 1 is provided with a slit 2 for passing through the glass liquid, and the length direction of the slit 2 is the same as the groove body 1 The length direction is the same, and the slit 2 is divided into the first width gradient slit 2-1, the middle equal width slit 2-2, the second width gradient slit 2-3, and the second width gradient slit 2-3 from one end to the other end along the length direction. The widths of the first width gradient slit 2-1 and the second width gradient slit 2-3 gradually decrease from one end close to the middle equal width slit 2-2 to the other end. During the forming process of the glass ribbon, due to the effect of the surface tension of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com