Optimally designed aspheric myopia lens and preparation mold thereof

An optimized design, aspherical technology, applied in the field of myopia lenses, can solve the problems of aspherical lenses, the actual perception effect of the human eye is not as good, the assembly is difficult to ensure accuracy, and the theoretical wearing effect is affected, so as to increase wearing comfort, reduce weight, The effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides an aspherical myopia lens with a diopter of -4D, the refractive index of the lens material is 1.56, and the lens diameter is ∮80. The front surface of the spectacle lens adopts an even aspheric refraction surface, and the rear surface is a spherical refraction surface.

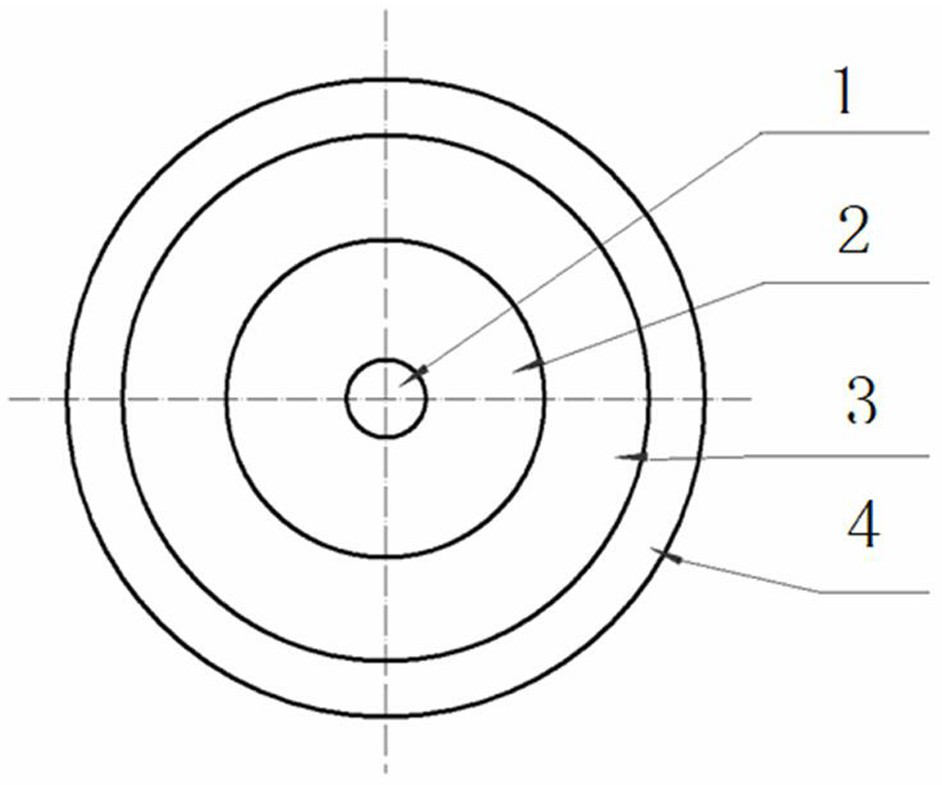

[0032] See attached figure 1 , is a structural schematic diagram of the aspheric myopia lens provided in this embodiment. The lens body is divided into four areas. The first area is the central photometric stability area 1, which is a circular area with a diameter of 5 mm; The axial aberration correction area 2 is an annular area with a diameter greater than 5 mm to 30 mm; the third area is the astigmatism control area 3, which is an annular area with a diameter greater than 30 mm to 66 mm; the fourth area is an annular area with a diameter greater than 5 mm to 30 mm; The annular area greater than 66 mm to the edge of the lens is the processing control area 4.

[0033] The opt...

Embodiment 2

[0059] This embodiment provides a lens whose diopter is -4D aspherical myopia lens, the refractive index of the lens material is 1.56, and the lens diameter is ∮80. The front surface of the spectacle lens is a spherical refraction surface, and the back surface is an even-numbered aspheric refraction surface.

[0060] The design method and design requirements are the same as those of Embodiment 1. According to the design requirements of the four partitions, this embodiment adopts ZEMAX programming to calculate and obtain the design parameters of the optimally designed aspheric myopia lens as shown in Table 3.

[0061] Table three:

[0062] .

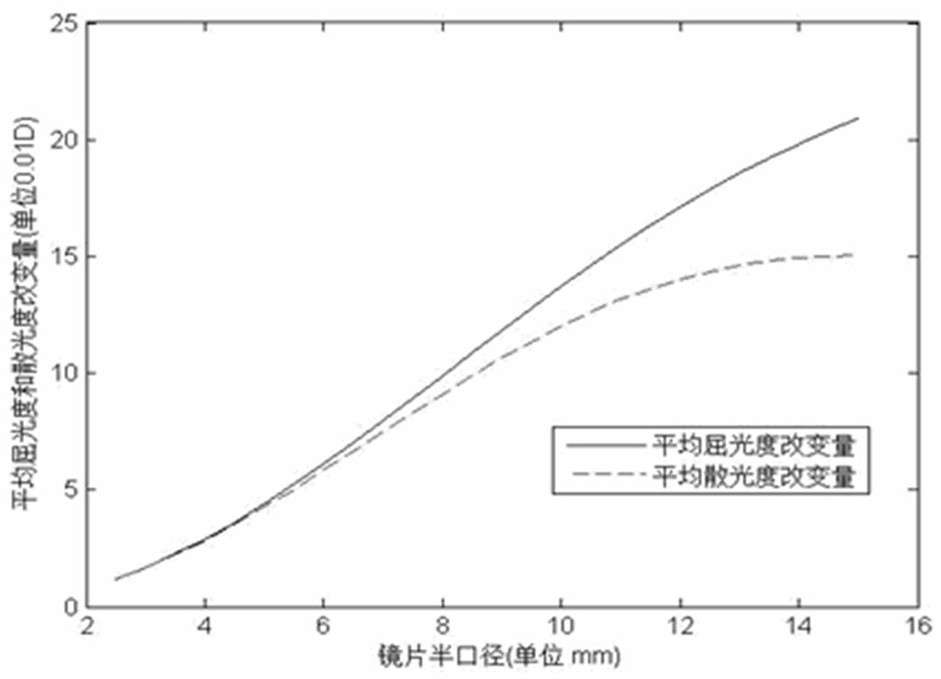

[0063] According to the design parameters in Table 3, using the ZEMAX program to calculate, within the scope of the first area, starting from the center of the lens, the diopter increases continuously; the change of the diopter at the center of the lens is zero, and the astigmatism is also zero. At the semi-diameter of 2.5mm (full-dia...

Embodiment 3

[0073] This embodiment provides a lens whose diopter is -4D aspherical myopia lens, the refractive index of the lens material is 1.56, the lens aperture is ∮80, and the front and rear surfaces of the lens are even-numbered aspheric refracting surfaces.

[0074] The design method and design requirements are the same as those of Embodiment 1. According to the design requirements of the four partitions, this embodiment adopts ZEMAX programming to calculate and obtain the design parameters of the optimally designed aspheric myopia lens, as shown in Table 5.

[0075] Table five:

[0076] .

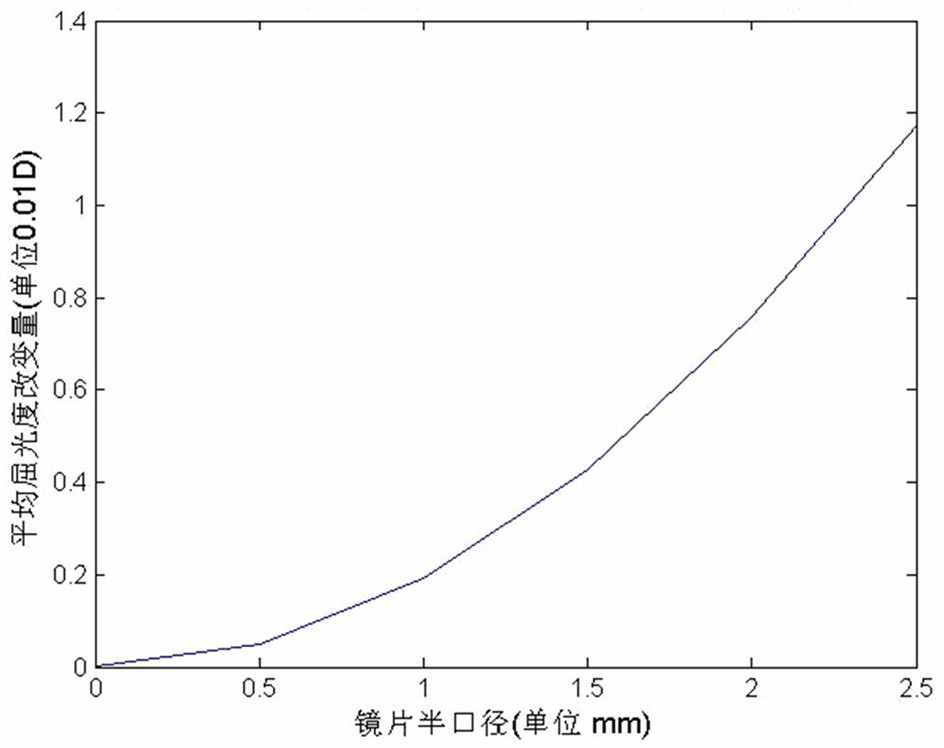

[0077]According to the parameters in Table 5, using the ZEMAX program to calculate the average diopter change of the optimally designed aspheric myopia lens within the scope of the first area is as follows: the change of the average diopter at the center of the lens is zero, and the change in the semi-diameter of 2.5mm (full aperture 5mm), the average diopter change of the lens is 0.0054D. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com