Preparation method of double-sided composite thinned and zooming myopic lens

A myopia lens, double-sided technology, applied in glasses/protective glasses, glasses/goggles, optics, etc., can solve problems such as violation of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a kind of double-sided composite thinning and zooming myopia lens, and its preparation method comprises the following steps:

[0034] S1: Establish the mathematical model of the front surface and the rear surface in the optical software,

[0035]

[0036] Among them, k 1 is the paraxial curvature of the front surface, k 2 is the paraxial curvature of the rear surface, p 1 is the aspheric coefficient of the front surface, p 2 is the rear surface aspheric coefficient, A is the high-order term coefficient, and x is the radial radius;

[0037] S2: Establish evaluation function

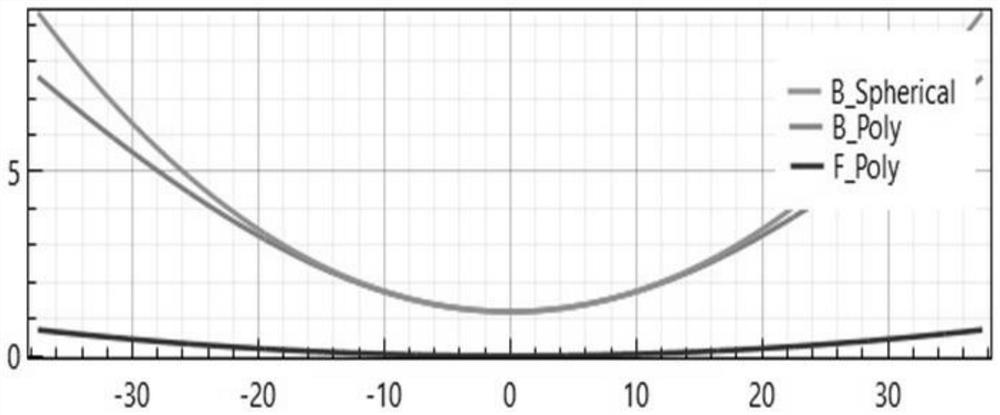

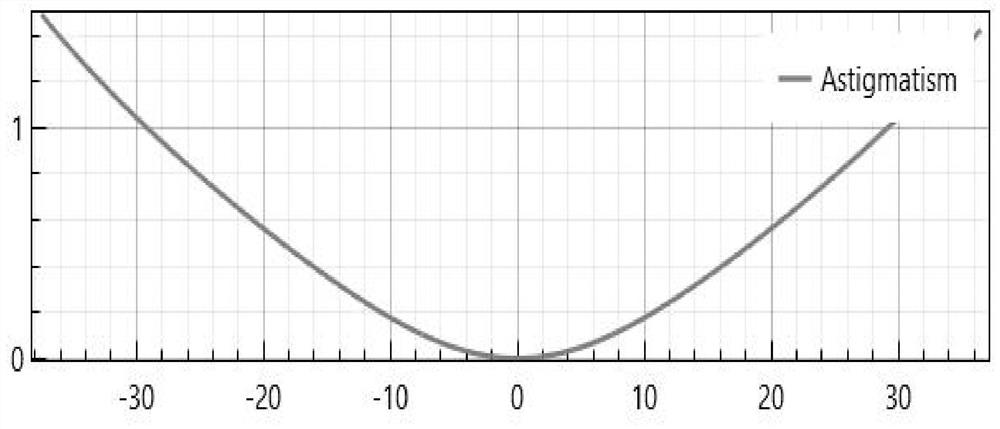

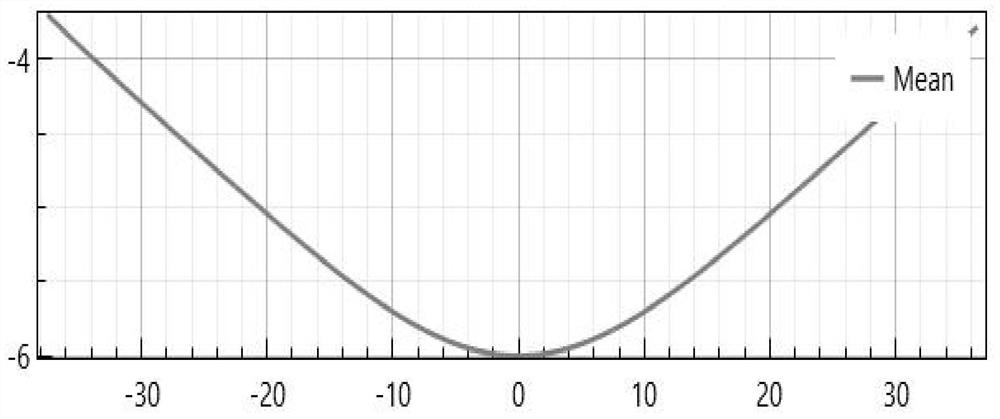

[0038] Design m=5, f 1 Optimized for astigmatism within a lens center radius of 10 mm, with a target value of 0; f 2 Optimized for astigmatism within a lens center radius of 20 mm, with a target value of 0, f 3 Optimized for astigmatism within a lens center radius of 25 mm and a target value of 0; f 4 is the power of the inner spherical lens with a radius of 5...

Embodiment 2

[0050] This embodiment provides a kind of double-sided composite thinning and zooming myopia lens, and its preparation method comprises the following steps:

[0051] S1: Establish the mathematical model of the front surface and the rear surface in the optical software,

[0052]

[0053] Among them, k 1 is the paraxial curvature of the front surface, k 2 is the paraxial curvature of the rear surface, p 1 is the aspheric coefficient of the front surface, p 2 is the rear surface aspheric coefficient, A is the high-order term coefficient, and x is the radial radius;

[0054] S2: Establish evaluation function

[0055] Design m=5, f 1 Optimized for astigmatism within a lens center radius of 10 mm, with a target value of 0; f 2 Optimized for astigmatism within a lens center radius of 20 mm, with a target value of 0; f 3 Optimized for astigmatism within a lens center radius of 25 mm and a target value of 0; f 4 is the power of the inner spherical lens with a radius of 5...

Embodiment 3

[0067] This embodiment provides a kind of double-sided composite thinning and zooming myopia lens, and its preparation method comprises the following steps:

[0068] S1: Establish the mathematical model of the front surface and the rear surface in the optical software,

[0069]

[0070]

[0071] Among them, k 1 is the paraxial curvature of the front surface, k 2 is the paraxial curvature of the rear surface, p 1 is the aspheric coefficient of the front surface, p 2 is the rear surface aspheric coefficient, A is the high-order term coefficient, and x is the radial radius;

[0072] S2: Establish evaluation function

[0073] Design m=5, f 1 Optimized for astigmatism within a lens center radius of 10 mm, with a target value of 0; f 2 Optimized for astigmatism within a lens center radius of 20 mm, with a target value of 0; f 3 Optimized for astigmatism within a lens center radius of 25 mm and a target value of 0; f 4 is the power of the inner spherical lens with a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com