Control method for reducing edge thickness of galvanized plate with super-thick zinc layer

A control method and technology of galvanized sheet, applied in coating, manufacturing tools, hot-dip plating process, etc., can solve the problems of increasing baffle sticking slag, slag easily hanging on strip steel, unable to meet multi-specification strip steel, etc. , to achieve the effect of avoiding too small rolling force, reducing edge thickness and avoiding wave shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

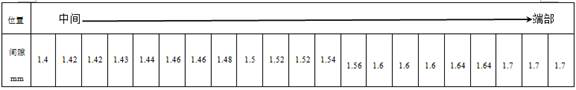

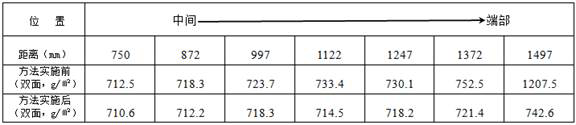

[0035] Galvanized sheet thickness specifications: 1.8mm, width 1500mm, zinc layer thickness 700g / ㎡, hot-rolled sheet as the substrate, convexity: 70μm, and after trimming, the end is smooth without burrs, and the annealing temperature is 670°C (plate Temperature), the temperature of entering the zinc pot is 465°C. The air knife gap is based on the middle 1.4mm, and gradually increases to both ends by 0.02-0.3mm, until it increases to 1.7mm and remains unchanged. The specific increments are: 0.02, 0.02, 0.03, 0.04, 0.06, 0.06, 0.08, 0.1, 0.12, 0.12, 0.14, 0.16, 0.2, 0.2, 0.2, 0.24, 0.24, 0.3, 0.3, 0.3mm, the gap value is shown in the table 1.

[0036] The air knife is a Posjet air knife with a lip length of 2000mm. It is treated with titanium nitride coating, which has the characteristics of high temperature resistance, not easy to adhere to zinc liquid, and easy to clean. The lip gap can be adjusted by manually adjusting the bolts, and the distance between each adjusting bol...

Embodiment 2

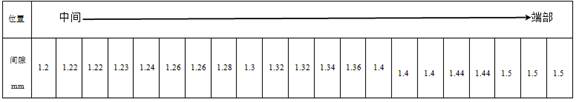

[0043] Galvanized sheet thickness specifications: 4.0mm, width 1500mm, zinc layer thickness 500g / ㎡, hot-rolled sheet as the substrate, convexity: 40μm, and after trimming, the end is smooth and burr-free. ), the temperature of entering the zinc pot is 460°C. The air knife gap is based on the 1.2mm in the middle, and gradually increases to the two ends with an increase of 0.02-0.3mm, until it increases to 1.5mm and remains unchanged. The specific increments are: 0.02, 0.02, 0.03, 0.04, 0.06, 0.06, 0.08, 0.1, 0.12, 0.12, 0.14, 0.16, 0.2, 0.2, 0.2, 0.24, 0.24, 0.3, 0.3, 0.3mm, the gap value is shown in the table 3. The air knife is the same as in Example 1.

[0044] The aluminum content in the zinc liquid composition needs to be controlled at 0.20%, the iron content ≤0.018%, the process speed is 30m / min, the air knife baffle is 2mm away from the edge of the strip steel, and after galvanizing, it goes through the skin pass process. 20μm, rolling force 4000KN. Before and after ...

Embodiment 3

[0050]Galvanized sheet thickness specifications: 3.0mm, width 1500mm, zinc layer thickness 600g / ㎡, hot-rolled sheet as the substrate, convexity: 50μm, and after trimming, the end is smooth and burr-free. ), the temperature of entering the zinc pot is 462°C. The air knife gap is based on the middle 1.3mm, and gradually increases to both ends by 0.02-0.3mm, until it increases to 1.6mm, it remains unchanged. The specific increments are: 0.02, 0.02, 0.03, 0.04, 0.06, 0.06, 0.08, 0.1, 0.12, 0.12, 0.14, 0.16, 0.2, 0.2, 0.2, 0.24, 0.24, 0.3, 0.3, 0.3mm, the gap value is shown in the table 5. The air knife is the same as in Example 1.

[0051] The aluminum content in the zinc liquid composition needs to be controlled at 0.22%, the iron content ≤0.018%, the process speed is 50m / min, the distance between the air knife baffle and the edge of the strip is 2mm, and after galvanizing, it goes through the skin pass process. 10μm, rolling force 3200KN. Before and after the implementation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com