Preparation method of aluminum iron oxide red ceramic pigment

A technology of ceramic pigments and aluminum iron, which is applied in the field of preparation of ceramic pigments, can solve problems such as high price of zirconium iron red, color difference in color, environmental pollution, etc., and achieve the effect of meeting aesthetic requirements, small color difference change, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

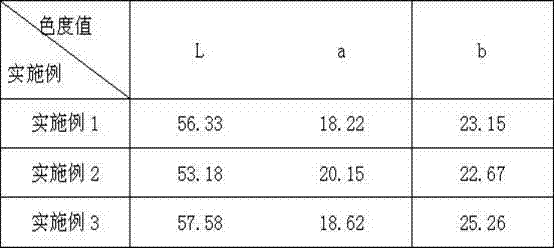

Embodiment 1

[0013] 1) First fill the ball mill with high alumina balls, the weight ratio of high alumina balls and materials is 5:1, and then cross feed the materials; the materials are calcined aluminum hydroxide with a weight percentage of 70% and aluminum oxide with a weight percentage of 30%, And sodium fluoride (i.e. mineralizer sodium salt) accounting for 1% of the total weight of calcined aluminum hydroxide and aluminum oxide, the above three raw materials are put into the ball mill crosswise to make these materials mix fully and uniformly; The time is 25 hours;

[0014] 2) Calcining the material obtained in the above step 1) in a kiln at 1050-1100°C for 6 hours;

[0015] 3) Pulverize the material obtained in step 2) to a particle size of less than 50 μm.

[0016] Press the prepared aluminum-iron red into the building ceramic base powder according to the addition amount of 2% (that is, the weight percentage of the aluminum-iron red in the building ceramic base powder), and then fi...

Embodiment 2

[0018] 1) First fill the ball mill with high alumina balls, the weight ratio of high alumina balls and materials is 5:1, and then cross-feed the materials; the materials are calcined aluminum hydroxide with a weight percentage of 75% and aluminum oxide with a weight percentage of 25%, As well as sodium fluoride (i.e. mineralizer sodium salt) accounting for 3% of the total weight of calcined aluminum hydroxide and aluminum oxide, the purpose of cross-feeding the above three raw materials into the ball mill is to make these materials mix fully and uniformly; Time is 30 hours;

[0019] 2) Calcining the material obtained in the above step 1) in a kiln at 1050-1100°C for 10 hours;

[0020] 3) Pulverize the material obtained in step 2) to a particle size of less than 50 μm.

[0021] Press the prepared aluminum-iron red into the building ceramic base powder according to the addition amount of 2% (that is, the weight percentage of the aluminum-iron red in the building ceramic base po...

Embodiment 3

[0023] 1) First fill the ball mill with high alumina balls, the weight ratio of high alumina balls and materials is 5:1, and then cross feed the materials; the materials are calcined aluminum hydroxide with a weight percentage of 80% and aluminum oxide with a weight percentage of 20%, And sodium fluoride (i.e. mineralizer sodium salt) accounting for 5% of the total weight of calcined aluminum hydroxide and aluminum oxide, the above three raw materials are put into the ball mill crosswise to make these materials mix fully and uniformly; Time is 40 hours;

[0024] 2) Calcining the material obtained in the above step 1) in a kiln at 1050-1100°C for 15 hours;

[0025] 3) Pulverize the material obtained in step 2) to a particle size of less than 50 μm.

[0026] Press the prepared aluminum-iron red into the building ceramic base powder according to the addition amount of 2% (that is, the weight percentage of the aluminum-iron red in the building ceramic base powder), and then fire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com