Aluminum alloyanode oxide film hole sealing agent and hole sealing method thereof

An anodized film and sealing agent technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve problems such as unfavorable dye fixation, color difference, escape, etc., to achieve good sealing effect and dye escape. The effect of less output and small chromatic aberration change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

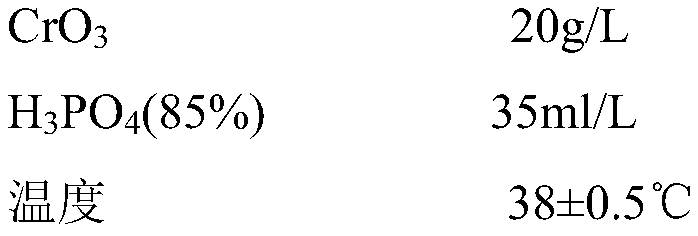

[0044] The sealing agent that present embodiment provides is composed as follows:

[0045]

[0046] The obtained sealing agent has high stability and strong impurity tolerance, and the solution is continuously kept at 90-95°C for 10 days without precipitation.

[0047] The process conditions used in the sealing step: pH value 5.2-5.7 (adjusted with acetic acid or ammonia water), temperature 90-95°C, sealing speed 1-2min / μm, film thickness 10μm, sealing time 20min.

[0048] There is no sealing dust and watermark on the surface of the aluminum alloy anodic oxidation film, and the weight loss test of phosphorus-chromic acid shows that the weight loss of the oxide film is 19.2mg / dm 2 , There is no decolorization phenomenon on the surface of the dyed anodized film, the color fixing ability is strong, and the color is uniform; the neutral salt spray test is carried out according to the ASTM B-117 standard for 72 hours, and the surface has no corrosion.

[0049] When the sealing ...

Embodiment 2

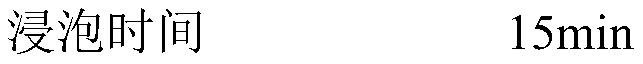

[0051] The sealing agent that present embodiment provides is composed as follows:

[0052]

[0053]

[0054] The obtained sealing agent has high stability and strong tolerance to impurities. The solution was continuously incubated at 85-90°C for 10 days without precipitation.

[0055] The process conditions used in the sealing step: pH value 5.2-5.7 (adjusted with acetic acid or ammonia water), temperature 85-90°C, sealing speed 1-2min / μm, film thickness 7μm, sealing time 15min.

[0056] There is no sealing dust and watermark on the surface of the aluminum alloy anodic oxidation film, and the weight loss test of phosphorus-chromic acid shows that the weight loss of the oxide film is 23.9mg / dm 2 , There is no dye escape on the surface of the dyed anodized film, the color fixing performance is good, and the color

[0057] Uniform without markings. According to the standard of ASTM B-117, the neutral salt spray test was carried out for 72 hours, and there was no corrosio...

Embodiment 3

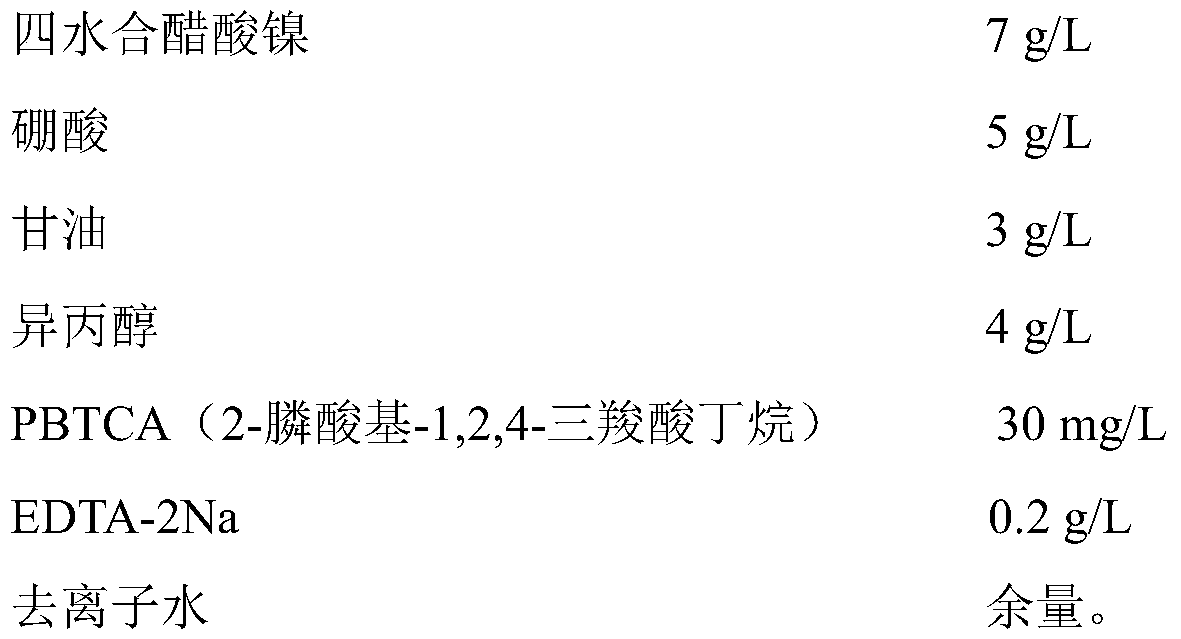

[0060] The sealing agent that present embodiment provides is composed as follows:

[0061]

[0062] The obtained sealing agent has high stability, and the solution is continuously kept at 85-90° C. for 10 days without precipitation.

[0063] The process conditions used in the sealing step: pH value 5.2-5.7 (adjusted with acetic acid or ammonia water), temperature 85-90°C, sealing speed 1-2min / μm, film thickness 12μm, sealing time 25min.

[0064] There is no sealing dust and watermark on the surface of aluminum alloy anodic oxidation film, and the weight loss test of phosphorus-chromic acid shows that the weight loss of the oxide film is 18.2mg / dm 2 , There is no decolorization phenomenon on the surface of the dyed anodized film, no dye escape, and good color fixing performance. According to the standard of ASTM B-117, the neutral salt spray test was carried out for 72 hours, and there was no corrosion on the surface.

[0065] When the sealing agent is used to dye the anodiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com