Preparation method of selenium-rich and zinc-rich whole-grain recombinant rice

A technology of whole grains and reconstituted rice, applied in the fields of food science, food ingredients, applications, etc., can solve the problems of palatability, poor cooking and digestibility, affecting health, and not suitable for large quantities of consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of preparation method of selenium-enriched, zinc whole grain recombined rice of the present embodiment comprises the following concrete steps:

[0047] (1) crushing and sieving: select brown rice with full grains as a raw material, pulverize the raw material brown rice, and cross an 80-mesh sieve to obtain brown rice flour;

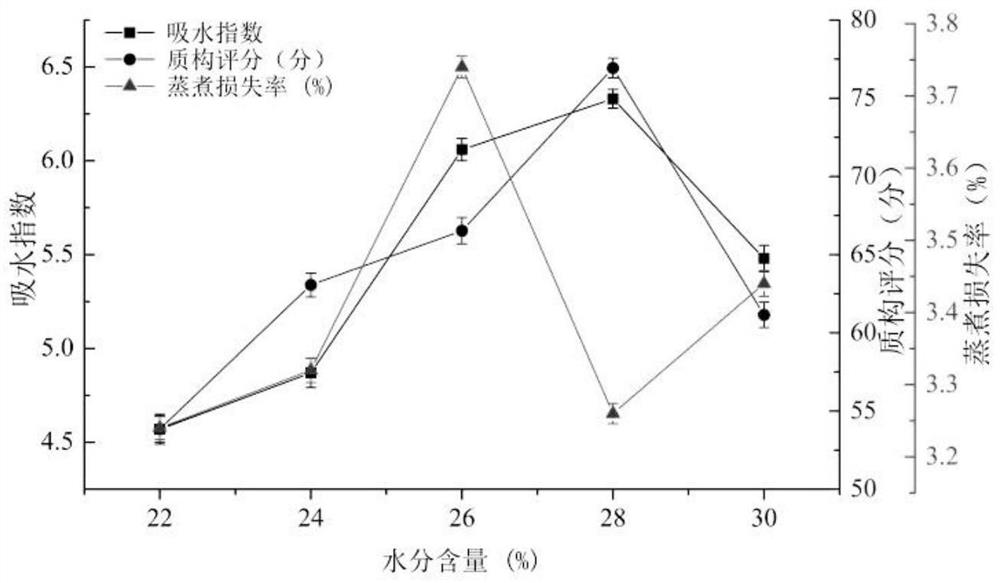

[0048] (2) Mixing and tempering: the brown rice flour obtained in step (1), L-selenium-methylselenocysteine MSC, L-zinc lactate and water are mixed evenly, and the mass ratio of water is adjusted to 25%, Modified milk is obtained; wherein, the added amounts of MSC and L-lactate are 460 μg / kg and 70 mg / kg respectively;

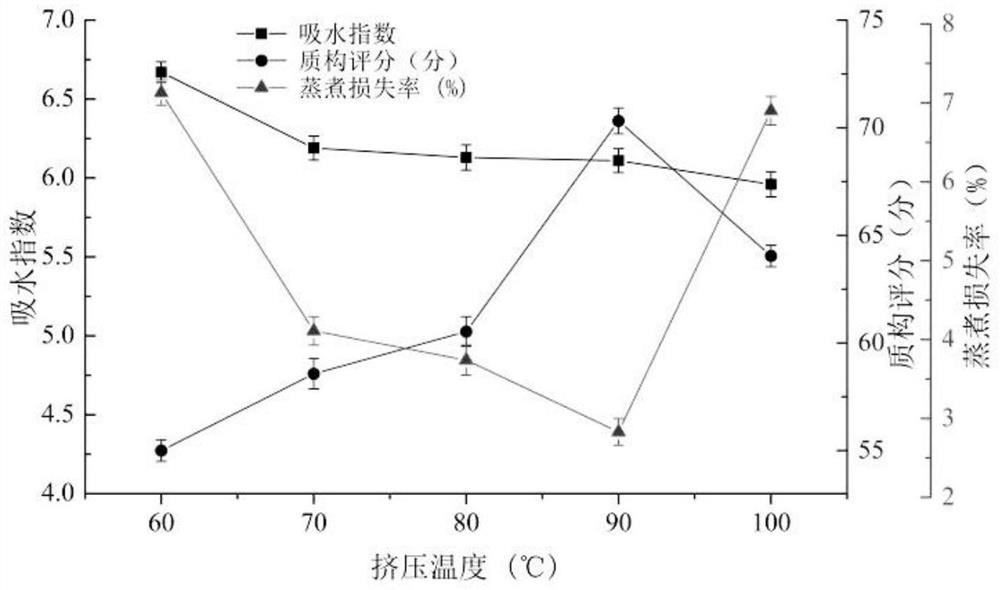

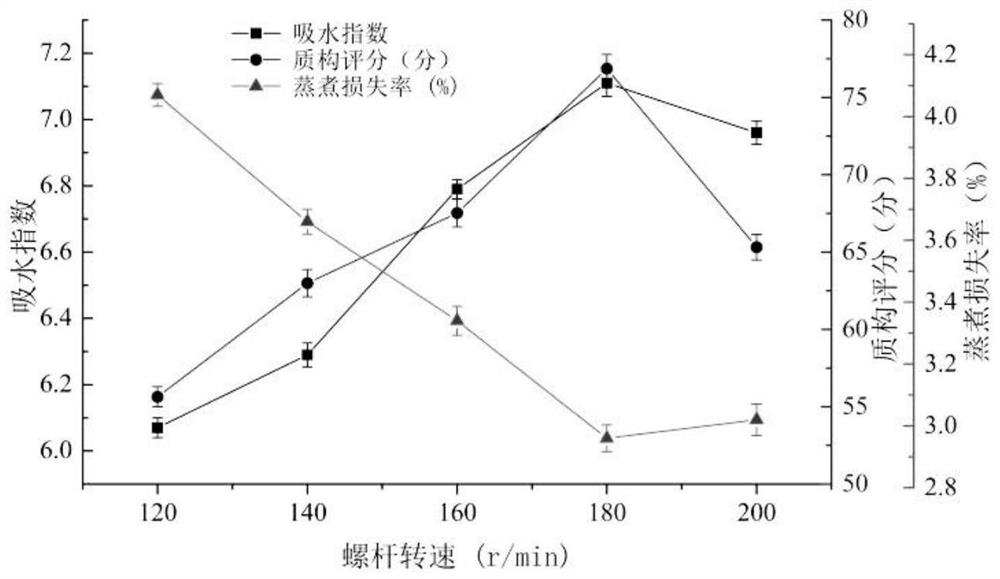

[0049] (3) Extrusion molding: Extrude and expand the modulated milk prepared in step (2) with a twin-screw extruder to obtain extruded granules; wherein, the extrusion temperature is 90°C, and the screw speed is 150r / min

[0050] (4) Drying: drying the extruded granules prepared in step (3) at 45° C. until the water conten...

Embodiment 2

[0052] A kind of preparation method of selenium-enriched, zinc whole grain recombined rice of the present embodiment comprises the following concrete steps:

[0053] (1) crushing and sieving: select brown rice with full grains as a raw material, pulverize the raw material brown rice, and cross an 80-mesh sieve to obtain brown rice flour;

[0054] (2) Mixing and tempering: mix the brown rice flour, L-selenium-methylselenocysteine MSC, L-lactate zinc and water obtained in step (1), and adjust the mass ratio of water to 30%. Modified milk is obtained; wherein, the added amounts of MSC and L-lactate are 460 μg / kg and 70 mg / kg respectively;

[0055] (3) Extrusion molding: Extrude and expand the modulated milk prepared in step (2) with a twin-screw extruder to obtain extruded granules; wherein, the extrusion temperature is 95°C, and the screw speed is 200r / min

[0056] (4) Drying: drying the extruded granules prepared in step (3) at 45° C. until the water content is 15%, to obtai...

Embodiment 3

[0058] A kind of preparation method of selenium-enriched, zinc whole grain recombined rice of the present embodiment comprises the following specific steps:

[0059] (1) crushing and sieving: select brown rice with full grains as a raw material, pulverize the raw material brown rice, and cross an 80-mesh sieve to obtain brown rice flour;

[0060] (2) Mixing and tempering: the brown rice flour obtained in step (1), L-selenium-methylselenocysteine MSC, L-zinc lactate and water are mixed evenly, and the mass ratio of water is adjusted to 28%. Modified milk is obtained; wherein, the added amounts of MSC and L-lactate are 460 μg / kg and 70 mg / kg respectively

[0061] (3) Extrusion molding: Extrude and expand the modulated milk prepared in step (2) with a twin-screw extruder to obtain extruded granules; wherein, the extrusion temperature is 92°C, and the screw speed is 180r / min ;

[0062] (4) Drying: drying the extruded granules prepared in the step (3) at 45° C. until the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fatty acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com