Method for synthesizing nano barium hydroxide wall painting reinforcing agent

A technology of barium hydroxide and reinforcing agent, applied in the direction of calcium/strontium/barium oxide/hydroxide, nanotechnology, nanotechnology, etc., can solve problems such as insufficient melting effect, limited penetration ability, small contact area, etc. , to achieve enhanced kinetic stability, simple components, and high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

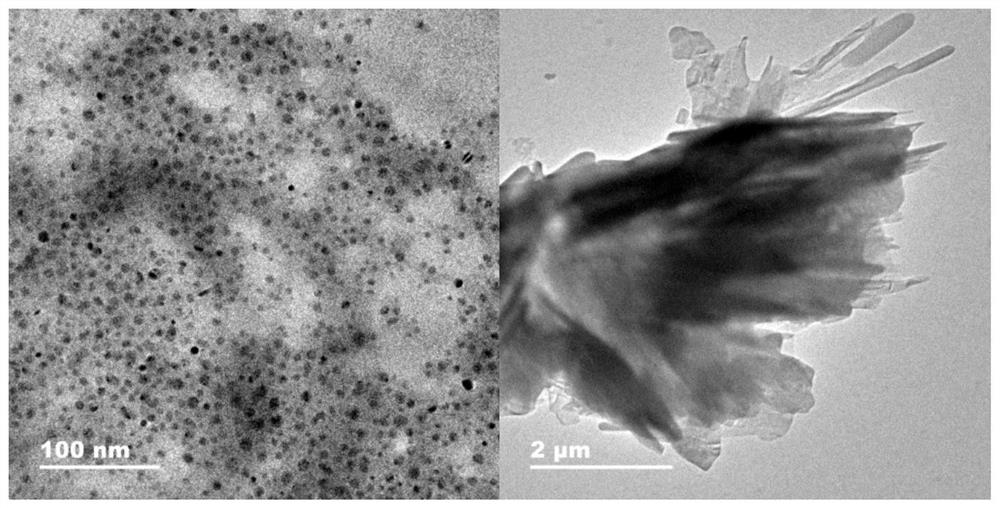

Embodiment 1

[0030] 24g BaCl 2 2H 2 O was dissolved in 900 mL of deionized water to obtain BaCl with a mass concentration of 2.6% 2 aqueous solution; 16 mL of ammonia water with a mass concentration of 28% was diluted to 100 mL with deionized water to obtain ammonia water with a mass concentration of 3.9%; under stirring, the above-mentioned ammonia water with a mass concentration of 3.9% was slowly added dropwise to a mass concentration of 2.6 % BaCl 2 In the aqueous solution, after the dropwise addition, continue to stir for 20 minutes, centrifugally wash with saturated barium hydroxide aqueous solution, and vacuum dry at 40°C for 12 hours to obtain nanometer Ba(OH) 2 Powder; 0.5g nanometer Ba(OH) 2 The powder was dispersed in 1L of methanol, and ultrasonically oscillated for 5 minutes to obtain nanometer Ba(OH) 2 Mural reinforcement.

Embodiment 2

[0032] 21g BaCl 2 2H 2 O was dissolved in 900 mL of deionized water to obtain BaCl with a mass concentration of 2.3% 2 aqueous solution; 14mL of ammonia water with a mass concentration of 28% was diluted to 100mL with deionized water to obtain ammonia water with a mass concentration of 3.5%; under stirring, the above-mentioned ammonia water with a mass concentration of 3.5% was slowly added dropwise to a mass concentration of 2.3 % BaCl 2 In the aqueous solution, after the dropwise addition, continue to stir for 15 minutes, centrifugally wash with saturated barium hydroxide aqueous solution, and vacuum dry at 40°C for 12 hours to obtain nanometer Ba(OH) 2 ; 0.5g nanometer Ba(OH) 2 The powder was dispersed in 1L ethanol, and ultrasonically oscillated for 5 minutes to obtain nanometer Ba(OH) 2 Mural reinforcement.

Embodiment 3

[0034] 26g BaCl 2 2H 2 O was dissolved in 900 mL of deionized water to obtain BaCl with a mass concentration of 2.8% 2 aqueous solution; 18mL of ammonia water with a mass concentration of 28% was diluted to 100mL with deionized water to obtain ammonia water with a mass concentration of 4.3%; under stirring, the above-mentioned ammonia water with a mass concentration of 4.3% was slowly added dropwise to a mass concentration of 2.8% % BaCl 2 In the aqueous solution, after the dropwise addition, continue to stir for 30 minutes, centrifugally wash with saturated barium hydroxide aqueous solution, and vacuum dry at 40°C for 12 hours to obtain nanometer Ba(OH) 2 ; 0.5g nanometer Ba(OH) 2 The powder was dispersed in 1L of isopropanol, and ultrasonically oscillated for 5 minutes to obtain nanometer Ba(OH) 2 Mural reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com