Boiling-resistant color-changing polypropylene composite material and preparation method thereof

A technology of composite materials and polypropylene, applied in the field of polypropylene materials, can solve problems such as discoloration, complaints, and affect consumers' use experience, and achieve the effect of low heat generation, strong dispersion ability, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

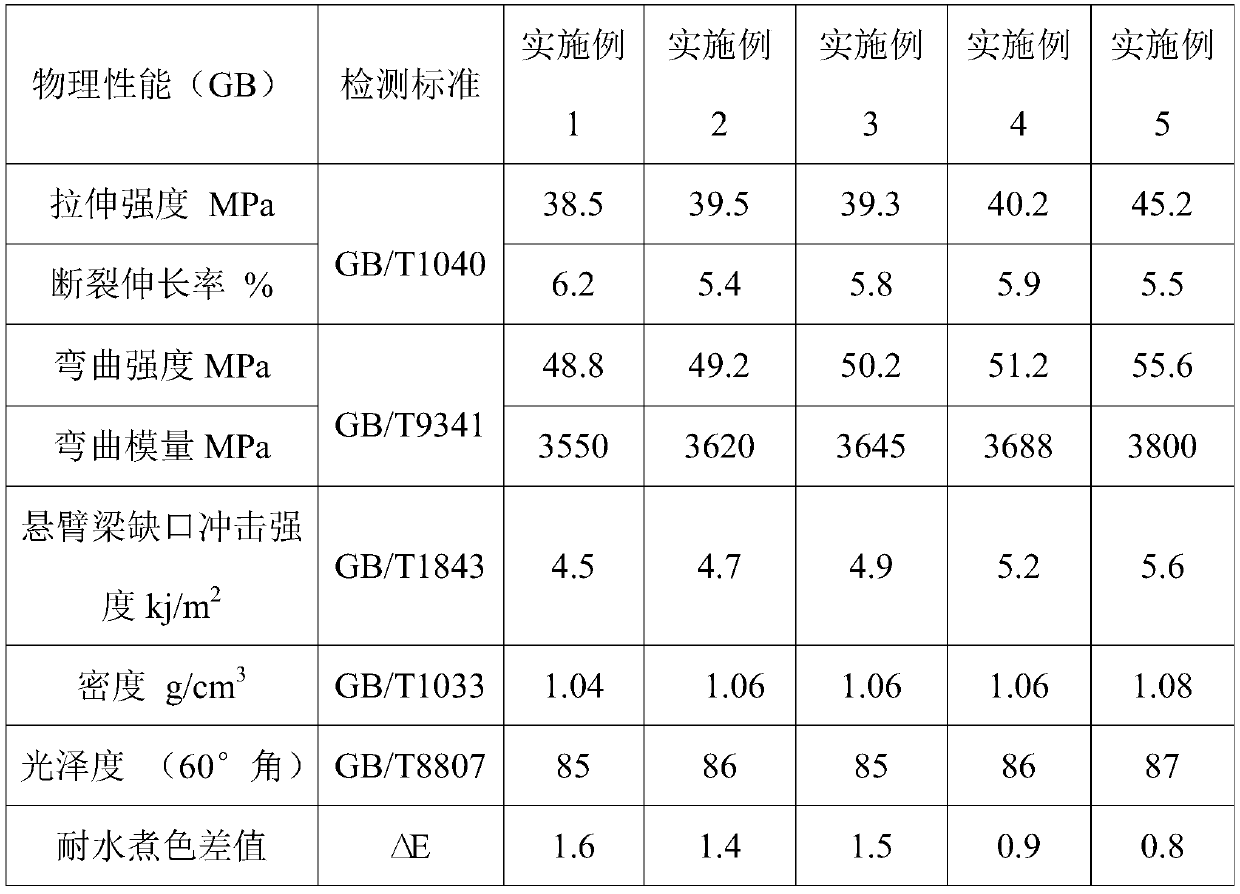

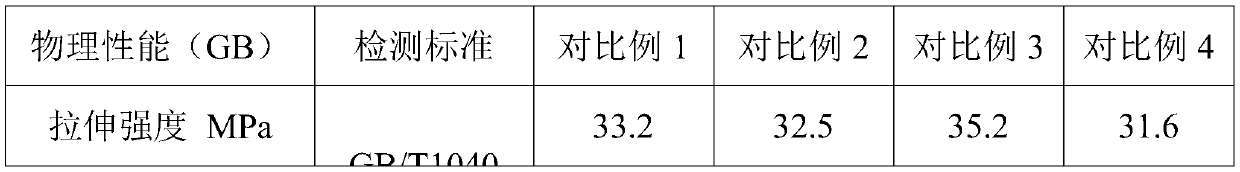

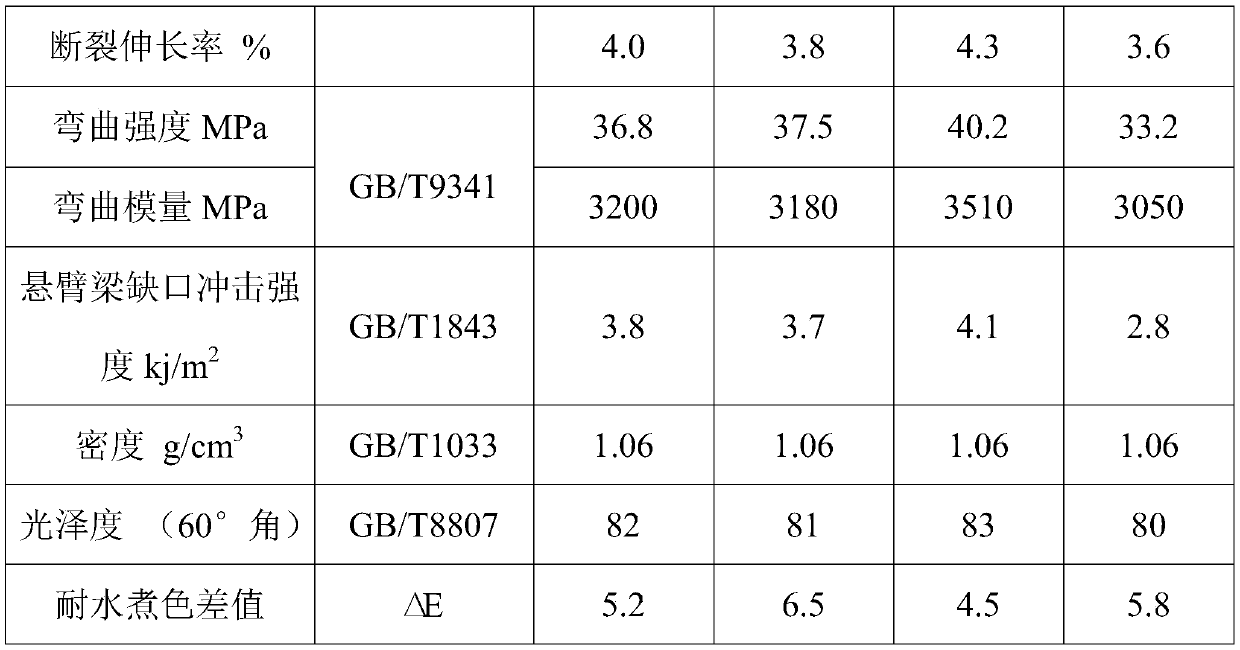

Examples

Embodiment 1

[0035] A kind of boil-resistant discoloration polypropylene composite material, its raw material comprises by weight: 90 parts of polypropylene resin, 2 parts of acrylonitrile-styrene copolymer, 2 parts of compatibilizer, 1 part of filler modifier, 5 parts of filler, 0.2 parts of antioxidant, 0.2 parts of weather resistance agent, 0.1 part of heat-resistant modifier, 0.5 parts of lubricant;

[0036] Wherein, the compatibilizer is polypropylene grafted styrene grafted maleic anhydride PP-PS-MAH, wherein, the maleic anhydride grafting rate is 0.5%;

[0037] In the preparation process of polypropylene-grafted styrene-grafted maleic anhydride PP-PS-MAH, dicumyl peroxide is dissolved in styrene, then mixed with polypropylene and maleic anhydride, and then melt-extruded A polypropylene-grafted styrene-grafted maleic anhydride PP-PS-MAH was obtained, wherein the weight ratio of polypropylene, styrene, maleic anhydride, and dicumyl peroxide was 93.6:5.0:1.4:0.2.

[0038] The preparat...

Embodiment 2

[0040] A kind of boil-resistant discoloration polypropylene composite material, its raw material comprises by weight: 77 parts of polypropylene resin, 6 parts of acrylonitrile-styrene copolymer, 4 parts of compatibilizer, 3 parts of filler modifier, 10 parts of filler, 0.3 parts of antioxidant, 0.3 parts of weather resistance agent, 0.7 parts of lubricant;

[0041] Wherein, the compatibilizer is polypropylene grafted styrene grafted maleic anhydride PP-PS-MAH, wherein, the maleic anhydride graft rate is 0.8%;

[0042] In the preparation process of polypropylene-grafted styrene-grafted maleic anhydride PP-PS-MAH, dicumyl peroxide is dissolved in styrene, then mixed with polypropylene and maleic anhydride, and then melt-extruded The polypropylene-grafted styrene-grafted maleic anhydride PP-PS-MAH was obtained, wherein the weight ratio of polypropylene, styrene, maleic anhydride, and dicumyl peroxide was 94.5:3.2:1.8:0.5.

[0043]The preparation method of the above-mentioned boi...

Embodiment 3

[0045] The weather-resistant agent is replaced with a heat-resistant modifier, and the others are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com