Overprinting glass manufacturing method and multi-color glass product

A kind of glass manufacturing, glass technology, applied in the field of overprint glass manufacturing method and multi-color glass products, can solve the problems of poor adhesion, discoloration phenomenon, poor scratch resistance test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

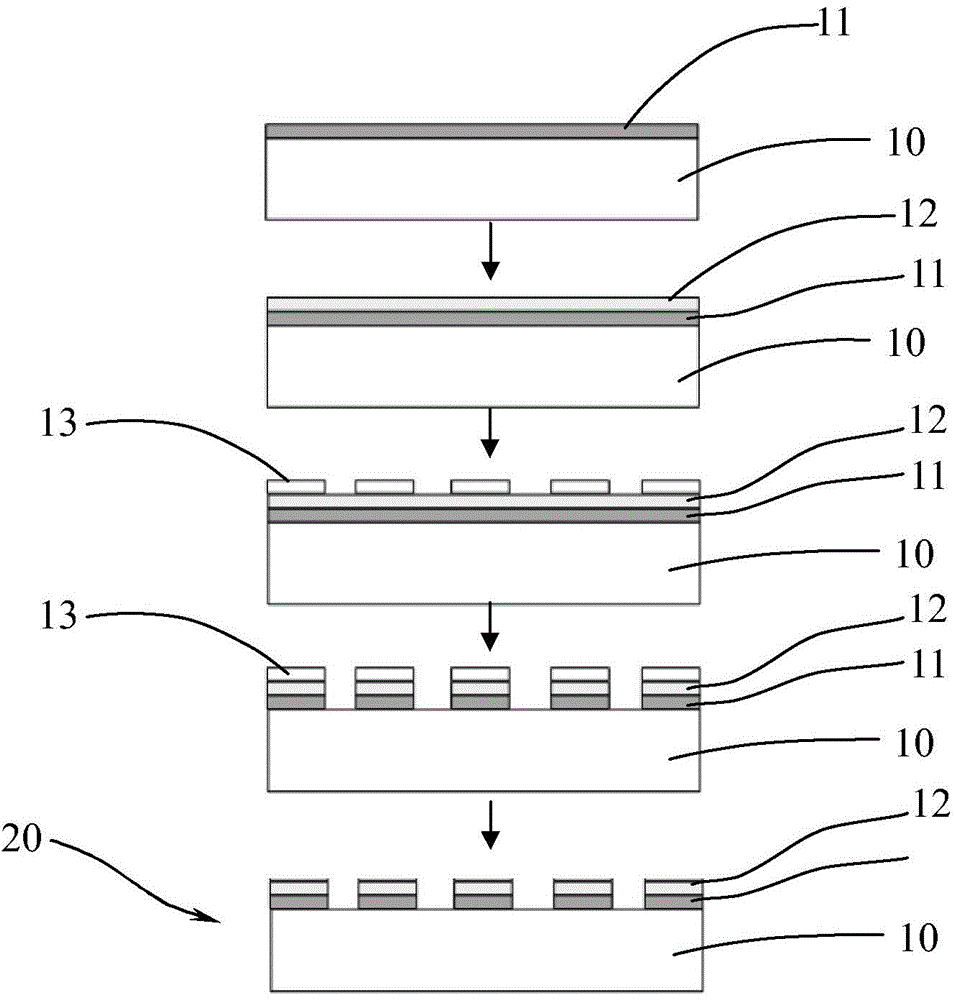

[0016] The present invention will be described in detail below with reference to specific embodiments and drawings.

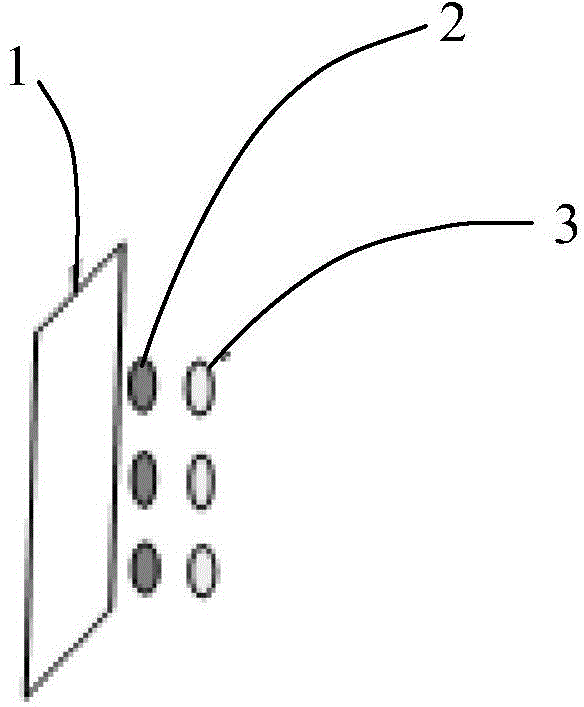

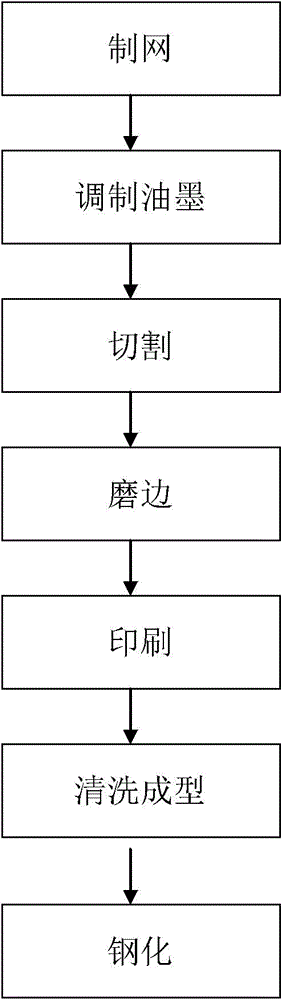

[0017] The method for manufacturing overprinted glass in the embodiment of the present invention mainly uses screen printing to produce highly decorative multilayer colored glass products. By first forming two or more ink layers and then washing, the desired pattern is formed at one time , So that the pattern of each layer is accurately aligned. The manufacturing method of overprint glass in the embodiment of the present invention includes the following steps:

[0018] Provide glass of predetermined size and two or more inks;

[0019] Screen making: make a screen, apply photosensitive material on the screen, and then use the film of the required pattern to expose and develop the shape;

[0020] Printing: The first ink is printed on the glass surface, dried to form the first ink layer, and then the second ink is printed on the first ink layer, and the second ink layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com