Color producing material with photonic crystal structure and preparation method thereof

A technology of structural color generation and photonic crystals, applied in the direction of organic dyes, etc., can solve the problems of dull, impure, and complex colors, and achieve the effect of bright colors and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

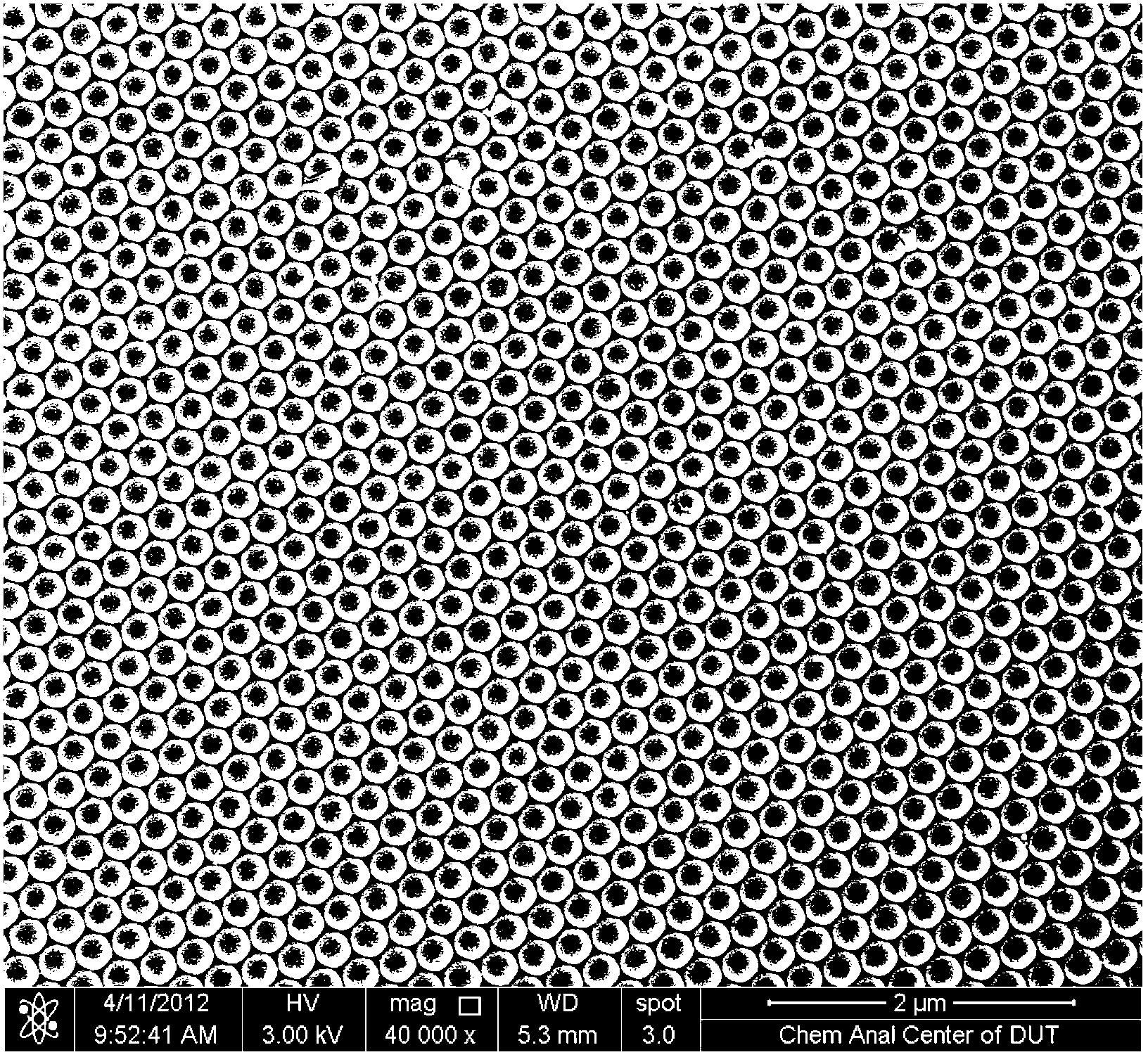

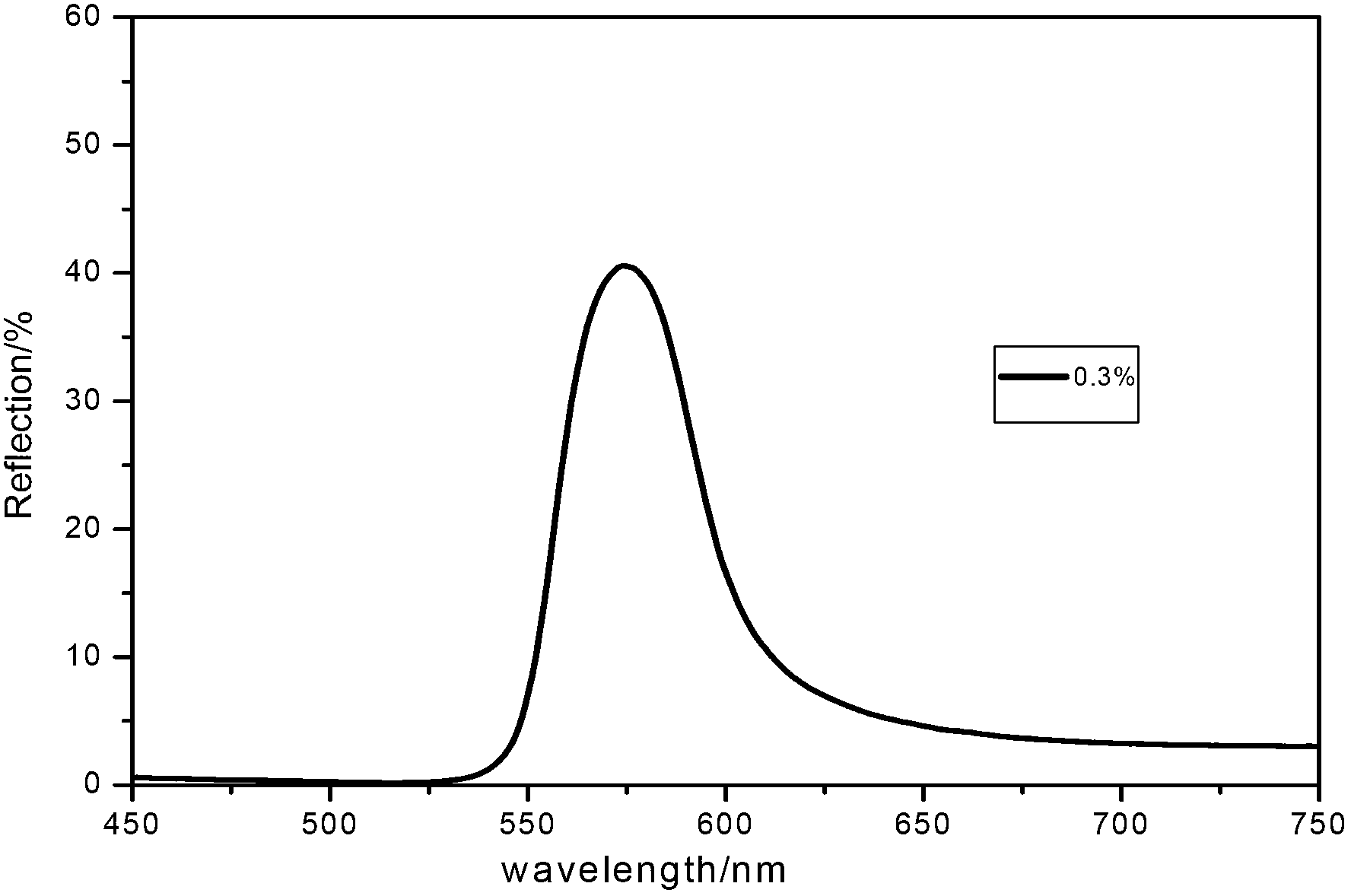

Embodiment 1

[0027] Weigh 2100.08g of acid black and dissolve it in 30ml of deionized water. Mix the aqueous solution of the dissolved black dye with the polystyrene microsphere emulsion with a mass percent concentration of 10% and a particle size of 230nm at a volume ratio of 1:3, ultrasonically disperse it for 10 minutes, and drop it evenly on a glass slide , and heated to 50 degrees Celsius at the bottom of the glass slide, and after the water evaporated, a brightly colored polystyrene photonic crystal was obtained.

Embodiment 2~25

[0029] Weigh 0.08g acid black 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23,234 replace the acid black 210 of embodiment 1, dissolve with 30ml deionized water, be made into aqueous solution, be 10% with concentration, particle diameter is after the polystyrene microsphere emulsion of 230nm is compounded by volume ratio 1:3, Ultrasonic disperse for 10 minutes, drop it evenly on the glass slide, and heat it to 50 degrees Celsius at the bottom of the glass slide. After the water evaporates, the polystyrene photonic crystal with bright color is obtained.

Embodiment 26~50

[0031] Weigh 0.08g direct black 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23, 24, 25 replace the acid black 210 of Example 1, dissolve with 30ml deionized water, make an aqueous solution, and the polystyrene microsphere emulsion with a concentration of 10% and a particle diameter of 230nm is compounded in a volume ratio of 1:3 , ultrasonically disperse for 10 minutes, drop it evenly on the glass slide, and heat it to 50 degrees Celsius at the bottom of the glass slide. After the water evaporates, the polystyrene photonic crystal with bright color is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com