Photo-cured high-temperature colored glass printing ink and preparation method therefor and painting method thereof

A color crystal glass and light-curing technology, which is applied in ink, household utensils, applications, etc., can solve the problems that cannot be re-registered and unsatisfactory, and achieve the effect of simple and easy preparation and use, and fast surface drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

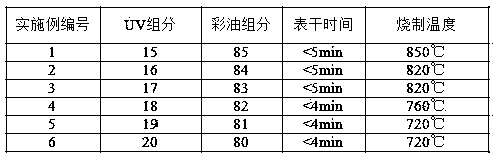

[0036] The content of the present invention is further described below by way of examples.

[0037] 1. Preparation of UV components

[0038] The composition and mass percentage of UV components are shown in the table below. The mass percentages of the additives used are: 0.8% of organosilicon, 0.6% of fatty acid polyethylene glycol ester, and 0.6% of silane coupling agent.

[0039] Preparation method: first take 50% of the active monomer to dissolve the photosensitive additive, and then feed in the order of the remaining 50% of the active monomer, additives, nano-ceramic resin, hexafunctional urethane acrylate, and monomer-dissolved photosensitive additive according to the formula Pour into a mixing container and stir well.

[0040]

[0041] The above UV component formula, after screen printing on glass products, can be cured within 5 minutes under the condition of ultraviolet light. The surface of the cured ink is dry and hard, which will not affect the secondary printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com