Test device and test method for simulating dam piping under high water-level condition

A simulation test, high water level technology, applied in measuring devices, soil material testing, material inspection products, etc., can solve problems such as the inability to effectively observe the change law of sand gushing time during the development and change of piping, and achieve fast monitoring and test error tolerance. High, simple principle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

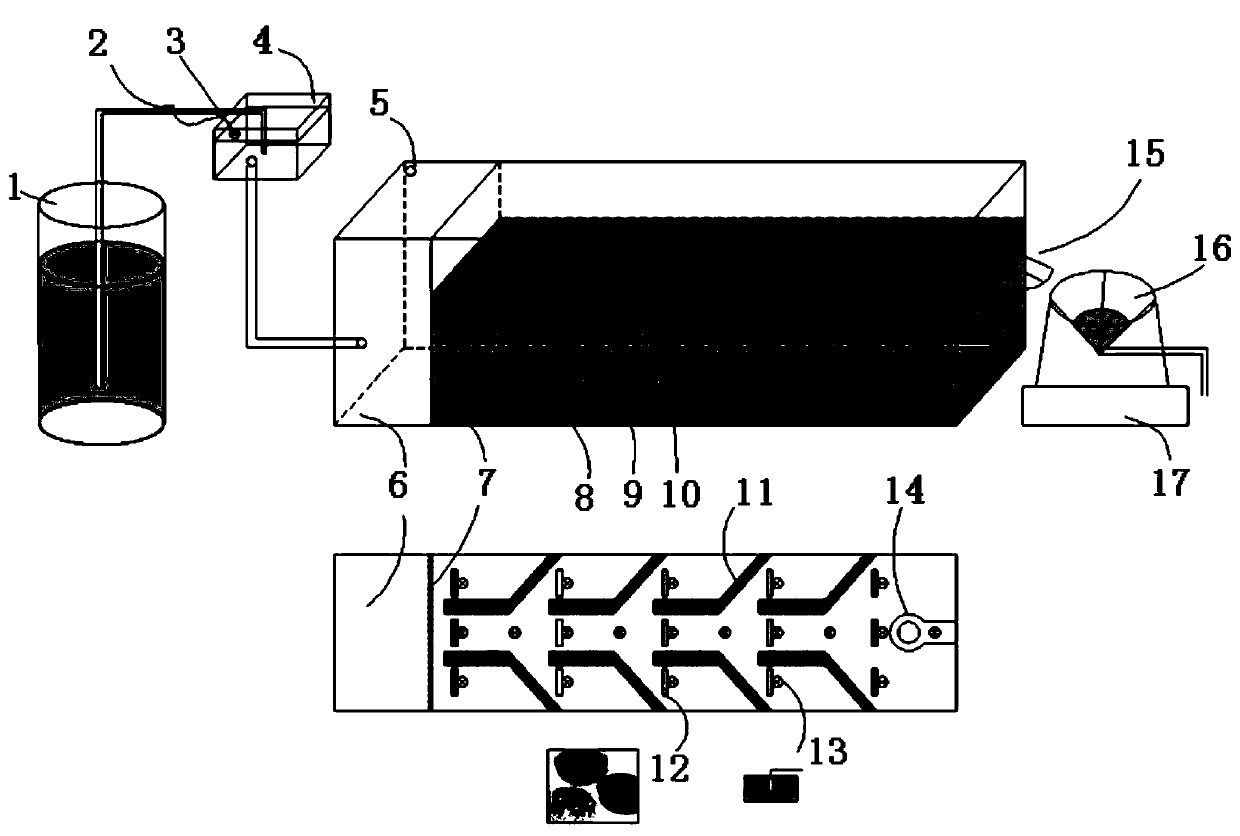

[0035] A dam piping simulation test device at a high water level, the device includes a test box, the test box is separated into a closed water storage chamber 6 and a soil sample filling room with an upper end opening through a permeable partition 7, and the soil sample filling room The test sand layer 9 with a certain thickness is filled indoors as required, in some embodiments, such as figure 1 As shown, the bottom of the test sand layer 9 is filled with a sand and gravel cushion 8, and the top is provided with a clay covering layer 10. Inside the test sand layer 9, colored glass beads 12, pore water pressure sensors 13 and coarse sand isolation belts 11 are arranged at different positions along the nozzle axis; Outlet 14, the piping outlet 14 is connected and drawn out through the water and sand discharge pipeline 15; Funnel 16; the funnel 16 is provided with a filtering device, and the filtered water is discharged through the drainage conduit at the bottom of the funnel ...

Embodiment 2

[0043] This embodiment is the test method of the embankment piping simulation test device under the high water level in the first embodiment, comprising the following steps:

[0044] 1) Fill a certain thick soil layer in the soil sample filling room according to the demand. The bottom layer is filled with sand and gravel cushion layer 8, the middle layer is the test sand layer 9, and the surface layer is laid with clay covering layer 10; 9 Lay three rows of colored glass beads 12 along the axial direction, and bury pore water pressure sensors 13 and coarse sand isolation belts 11 in the test sand layer 9 at the same time.

[0045] 2) Turn on the water pump 2 to pump water from the water storage tank 1 into the pressure regulating water tank 4, the water flows into the water storage chamber 6 through the pipeline, keep the permeable partition 7 closed, and open the permeable partition when the water level in the water storage chamber 6 rises to the required height Plate 7 was t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com