Preparation method for colored glass beads

A technology of colored glass and glass beads, applied in glass manufacturing equipment, glass molding, glass production, etc., can solve the problems of unsatisfactory process, high production cost, unstable color, etc., and achieve excellent decorative effect and production Cost reduction, good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

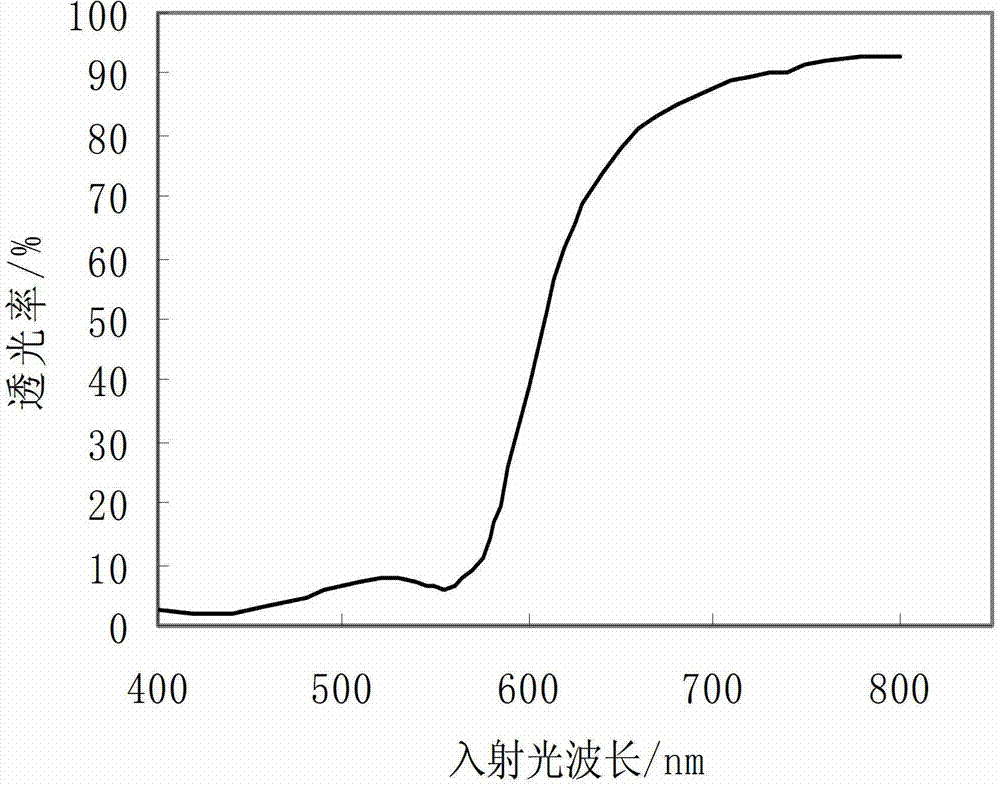

Image

Examples

Embodiment 1

[0027] Embodiment 1, the first step: the preparation of matrix glass microspheres

[0028] 1) First, 68.5% SiO 2 , 9% CaO, 16% Na 2 O, 2% K 2 O, 2% Al 2 o 3 , 2% ZnO and 0.5% Sb 2 o 3 After the powder is mixed evenly, a batch material is formed;

[0029] The SiO 2 Introduced through quartz sand, the purity is 99.9%, the particle size is 150 mesh, CaO, Na 2 O, K 2 O, Al 2 o 3 , ZnO, Sb 2 o 3 They are respectively introduced by analytically pure calcium carbonate, sodium carbonate, potassium carbonate, aluminum hydroxide, zinc oxide, and antimony trioxide;

[0030]2) It will add half of the batch materials into the corundum crucible that has been heated to 1300 °C; then, heat up to 1450 °C in 10 minutes and keep it warm for 20 minutes; then add the remaining batch materials into the corundum crucible and heat up to 10 minutes 1400°C, after 60 minutes of heat preservation, pour the melted glass into water and quench it;

[0031] 3) Then, fish out the glass slag aft...

Embodiment 2

[0042] Embodiment 2, the first step: the preparation of matrix glass microsphere

[0043] 1) First, 63% SiO 2 , 9% CaO, 18% Na 2 O, 3% K 2 O, 3% Al 2 o 3 , 3% ZnO and 31% Sb 2 o 3 After the powder is mixed evenly, a batch material is formed;

[0044] The SiO 2 Introduced through quartz sand, the purity is 99.9%, the particle size is 150 mesh, CaO, Na 2 O, K 2 O, Al 2 o 3 , ZnO, Sb 2 o 3 They are respectively introduced by analytically pure calcium carbonate, sodium carbonate, potassium carbonate, aluminum hydroxide, zinc oxide, and antimony trioxide;

[0045] 2) It will add half of the batch materials into the corundum crucible that has been heated to 1300 °C; then, heat up to 1450 °C in 10 minutes and keep it warm for 20 minutes; then add the remaining batch materials into the corundum crucible and heat up to 10 minutes 1420°C, after holding for 60 minutes, pour the molten glass into water and quench it;

[0046] 3) Then, fish out the glass slag after water que...

Embodiment 3

[0056] Embodiment 3, the first step: the preparation of matrix glass microsphere

[0057] 1) First, mix 70% SiO by mass fraction 2 , 5% CaO, 15% Na 2 O, 3% K 2 O, 3% Al 2 o 3 , 3% ZnO and 1% Sb 2 o 3 After the powder is mixed evenly, a batch material is formed;

[0058] The SiO 2 Introduced through quartz sand, the purity is 99.9%, the particle size is 150 mesh, CaO, Na 2 O, K 2 O, Al 2 o 3 , ZnO, Sb 2 o 3 They are respectively introduced by analytically pure calcium carbonate, sodium carbonate, potassium carbonate, aluminum hydroxide, zinc oxide, and antimony trioxide;

[0059] 2) It will add half of the batch materials into the corundum crucible that has been heated to 1300 °C; then, heat up to 1450 °C in 10 minutes and keep it warm for 20 minutes; then add the remaining batch materials into the corundum crucible and heat up to 10 minutes 1410°C, after 60 minutes of heat preservation, pour the melted glass into water and quench it;

[0060] 3) Then, fish out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com