Processing method of three-dimensional colored ice crystal glass

A technology of ice crystal glass and a processing method, which is applied in the processing field of three-dimensional colored ice crystal glass, can solve problems such as poor three-dimensional effect, high cost, and expanded layer limit in the application field, and achieve reasonable layered structure, simple method, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

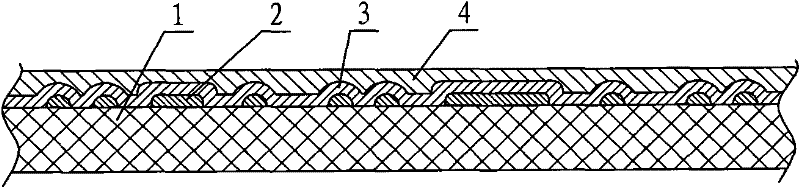

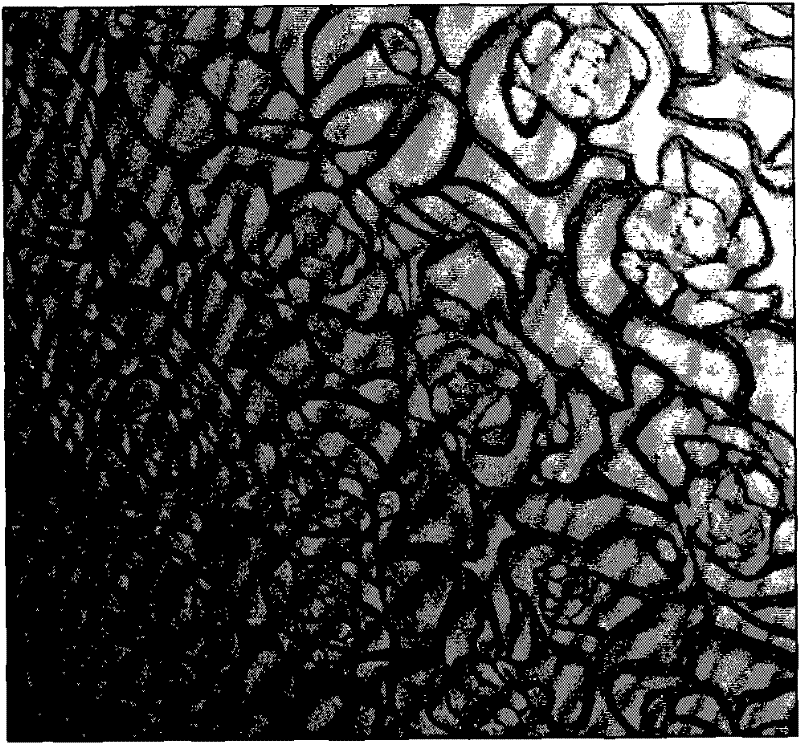

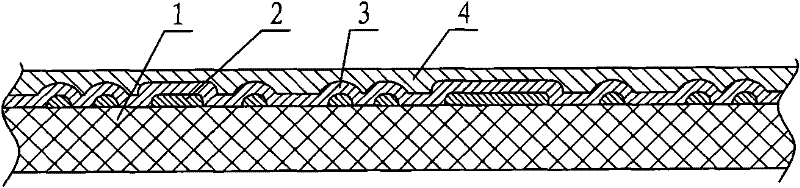

[0013] Depend on Figure 1-2 As shown, 1 in the figure is the glass substrate layer. First, the glass used as the glass substrate layer 1 is cleaned and dried for later use; then a solid-color skeleton capable of forming a pattern is printed on one side of the glass substrate layer by a screen printing machine Layer 2, the solid-color skeleton layer is selected from the GPK-1005 three-dimensional varnish produced by "Mogao Ink (Guangzhou) Co., Ltd.", and it is used after drying; Effect of the color modified epoxy resin paint layer 3, the color modified epoxy resin paint layer is selected from the production of "Lanhai Paint Co., Ltd." in Donggang District, Rizhao City, Shandong Province, model: LH-210, colored glass paint; when After spraying the color-modified epoxy resin layer 3, tilt the glass substrate at 10-20 degrees and let it stand for 5-10 minutes, so that the spray-coated color-modified epoxy resin layer can flow properly, and then dry; On the epoxy resin layer 3, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com