Spectrum local decorated thermocolour glass and method for making same

A glass and thermochromic technology, applied in the field of thermochromic glass and its preparation, can solve problems such as unfavorable industrialization promotion and application, multi-film structure increases preparation cost, etc., and achieves the effect of enhanced performance and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Thermochromic glass with locally modified spectrum, including matrix quartz glass and vanadium dioxide film, on which Ag nanoparticles are deposited.

[0025] (2) Preparation method:

[0026] VO 2 The films and Ag nanoparticles were prepared by magnetron sputtering. The magnetron sputtering system consists of a transition chamber and a main sputtering chamber (45 cm in diameter). The main sputtering chamber is connected with a molecular diffusion pump, and the ultimate vacuum is 2.0×10 -6 Pa. The sputtering chamber has three target positions for three different 2-inch diameter targets. Each target position is inclined upward at an angle of 30°, and can be co-sputtered upwards in a confocal manner or sputtered upwards in a three-target independent manner. The sample stage can be heated up to over 600°C and can keep rotating continuously during the sputtering process.

[0027] In this experiment, the substrate (substrate) is made of quartz glass. The substrate ...

Embodiment 2

[0033] (1) Thermochromic glass with locally modified spectrum, including matrix quartz glass and vanadium dioxide film, on which Ag nanoparticles are deposited.

[0034] (2) Preparation method:

[0035] The experimental process and parameter setting are the same as those in Example 1, except that Ag is sputtered for 5 minutes. At this time VO 2 The mass thickness of Ag nanoparticles deposited on the film is about 10nm.

[0036] The results of AFM measurement are: the Ag nanoparticles are mainly oblate and the average diameter of the parallel film surface is about 110nm, and they are evenly distributed in the VO 2 the surface of the film.

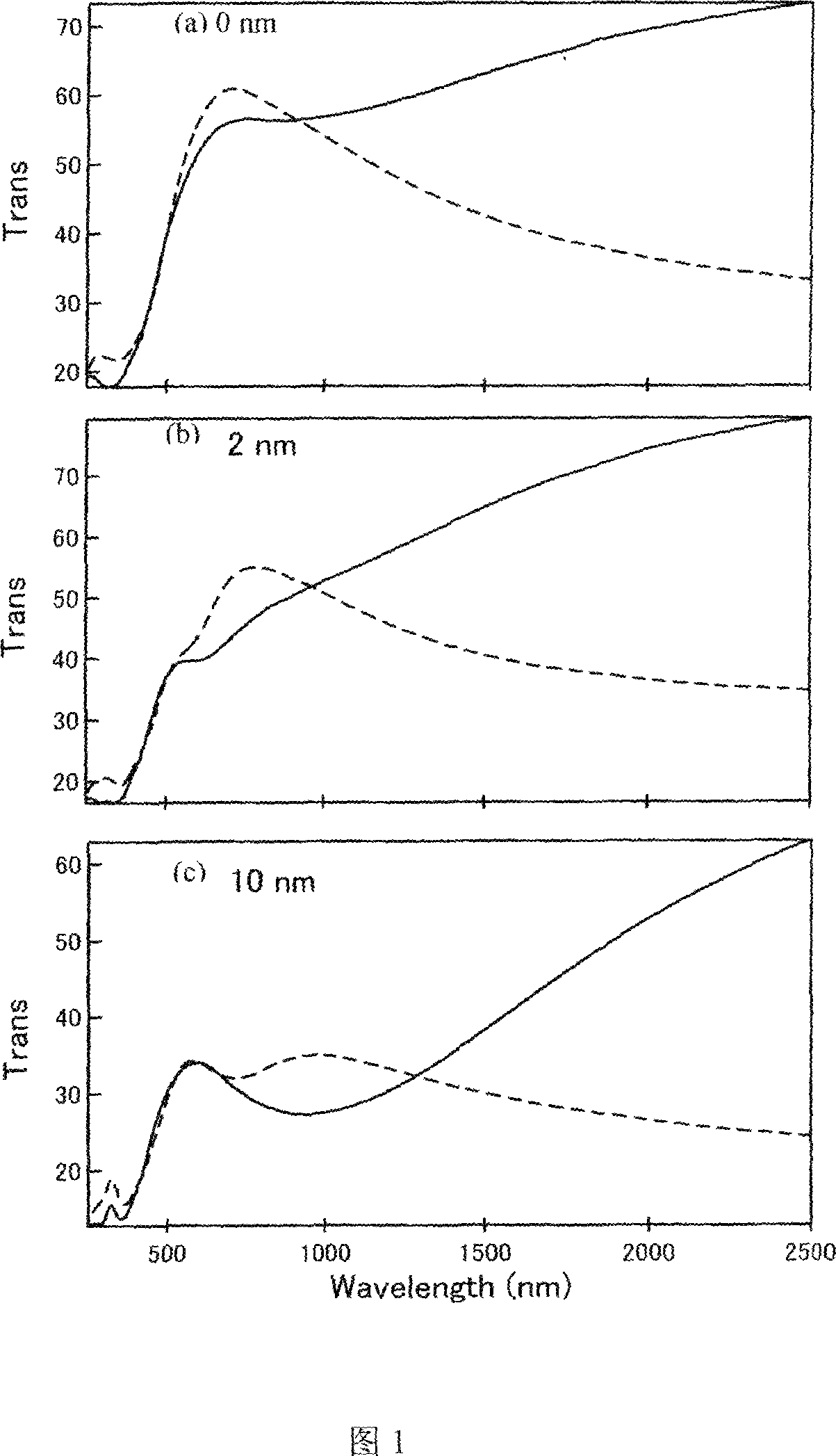

[0037] The results of thermochromic spectroscopy show that: at room temperature, Ag nanoparticles 2 The band of the modified effect produced by the transmission spectrum is located near 1000nm; at high temperature, the modified band is located near 750nm. As shown in Figure 1(c).

Embodiment 3

[0039] (1) Thermochromic glass with locally modified spectrum, including matrix quartz glass and vanadium dioxide film, and Au nanoparticles are deposited in the film layer of vanadium dioxide film.

[0040] (2) Preparation method:

[0041] The preparation method of vanadium dioxide is the same as Example 1. The preparation of Au nanoparticles is exactly the same as the preparation of Ag nanoparticles in Example 1, the difference is that the sputtering target material Ag target is replaced by Au target. The preparation process is as follows: first deposit vanadium dioxide film, the deposition time is 30 minutes; then deposit Au nanoparticles according to the deposition conditions of Example 1, sputtering time is 5 minutes; after that, continue to deposit vanadium dioxide, the deposition time is 30 minutes. At this time, the Au nanoparticles are embedded in the vanadium dioxide film layer (the spherical polyhedron of the Au nanoparticles is tested by TEM, and the average parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com