Waterproof paint

A technology for waterproof coatings and raw materials, applied in the field of architectural coatings and waterproof coatings, can solve the problems of unstable quality, poor low temperature flexibility and crack resistance, limited application scope, etc., and achieve excellent mechanical properties and good flame retardant effect. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

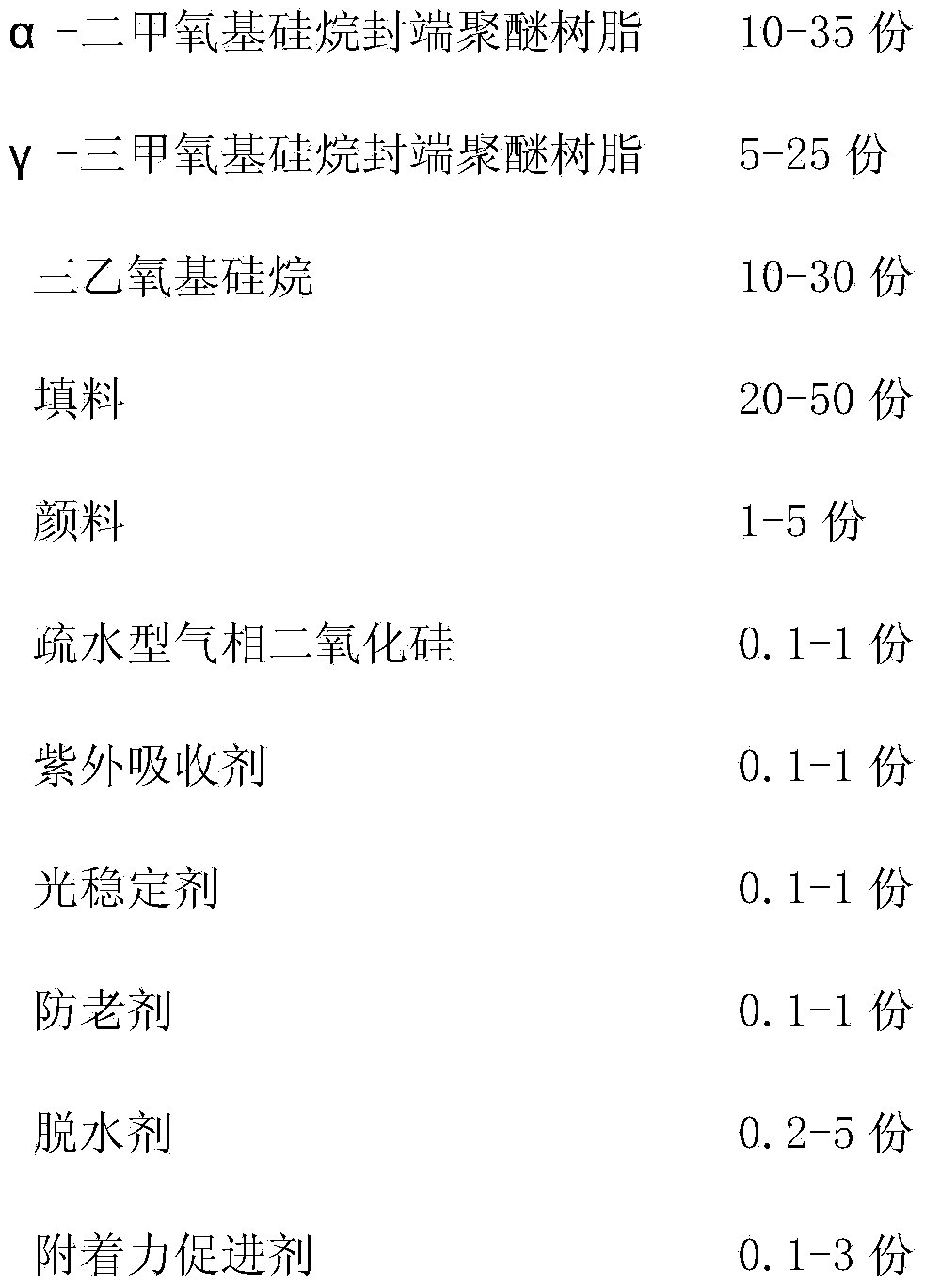

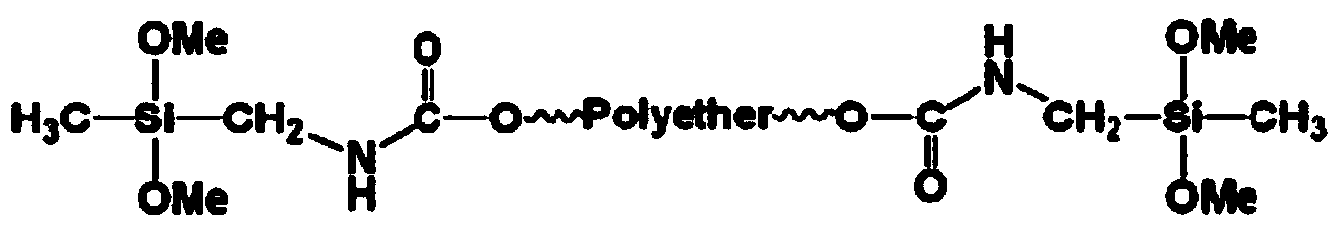

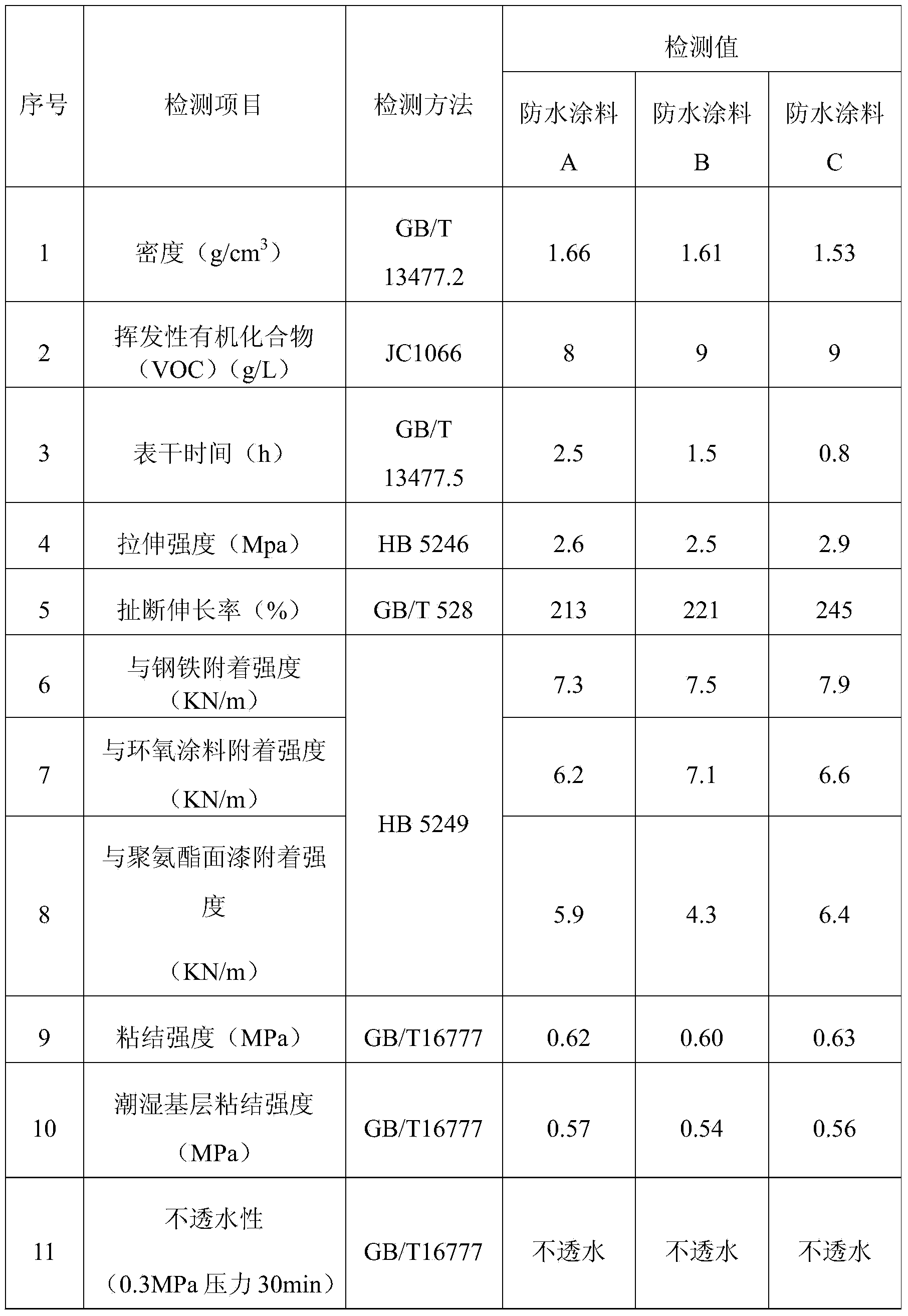

[0019] A waterproof coating, its raw material composition and preparation process are as follows: Weigh 10 parts of STP-E10, 15 parts of STP-E15, 25 parts of isooctyltriethoxysilane, 28 parts of heavy calcium carbonate, and 15 parts of nano-active Calcium carbonate, 1 part of hydrophobic fumed silica, 0.4 part of carbon black, 0.3 part of UV absorber, 0.3 part of light stabilizer, 0.3 part of anti-aging agent, put them together in a double planetary mixer, vacuumize and stir evenly, then add 0.8 part Dehydrating agent, vacuumize and stir for 15 minutes, add 1.0 parts of adhesion promoter, vacuumize and stir for 15 minutes, and discharge to obtain waterproof coating A. The performance test results are shown in Table 1.

Embodiment 2

[0021] A waterproof coating, its raw material composition and preparation process are as follows: Weigh 13 parts of STP-E10, 10 parts of STP-E15, 26 parts of isooctyltriethoxysilane, 15 parts of heavy calcium carbonate, and 22 parts of nano-active Calcium carbonate, 1 part of hydrophobic fumed silica, 2 parts of carbon black, 6 parts of aluminum hydroxide flame retardant, 0.3 part of ultraviolet absorber, 0.3 part of light stabilizer, 0.3 part of anti-aging agent, put them into a double planetary mixer together, After vacuuming and stirring evenly, add 1.2 parts of dehydrating agent, after vacuuming and stirring for 15 minutes, add 1.2 parts of adhesion promoter, vacuumize and stir for 15 minutes, and discharge to obtain waterproof coating B. The performance test results are shown in Table 1.

Embodiment 3

[0023] A waterproof coating, its raw material composition and preparation process are as follows: Weigh 11 parts of STP-E10, 12 parts of STP-E15, 25 parts of isooctyltriethoxysilane, 30 parts of heavy calcium carbonate, and 10 parts of nano-active Calcium carbonate, 8 parts of magnesium hydroxide flame retardant, 0.3 parts of UV absorber, 0.3 parts of light stabilizer, 0.3 parts of anti-aging agent, put them together in a double planetary mixer, and after vacuuming and stirring evenly, add 0.9 parts of dehydrating agent and vacuumize After stirring for 15 minutes, add 1.1 parts of adhesion promoter, vacuumize and stir for 15 minutes, and then discharge to obtain waterproof coating C. The performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com