Automatic paint spraying equipment for pickaxe

An automatic painting and pickaxe technology, applied in the direction of the spraying device, can solve the problems of flying everywhere, affecting the surrounding environment, needing to turn the pickaxe, etc., to achieve the effect of avoiding rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

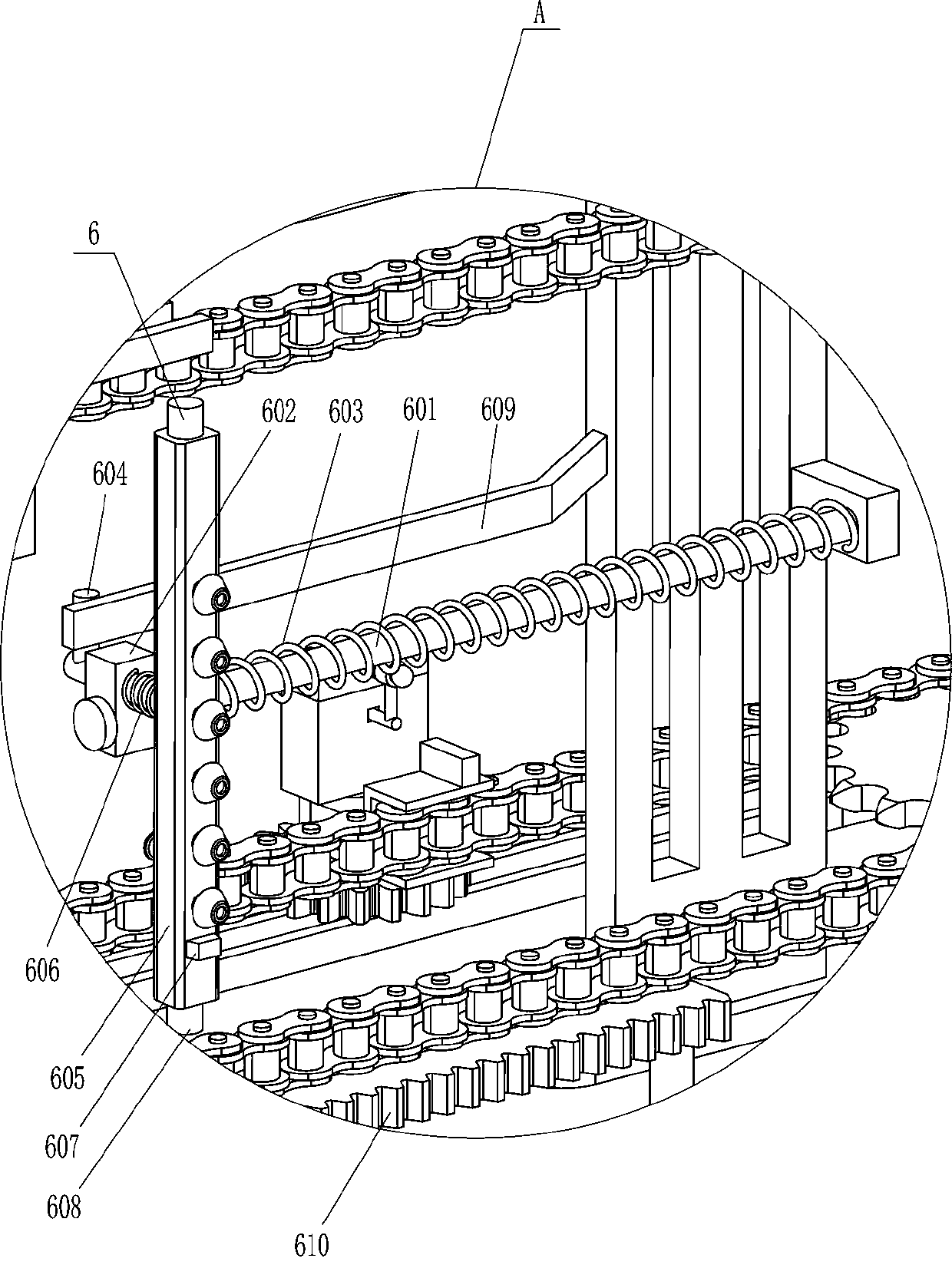

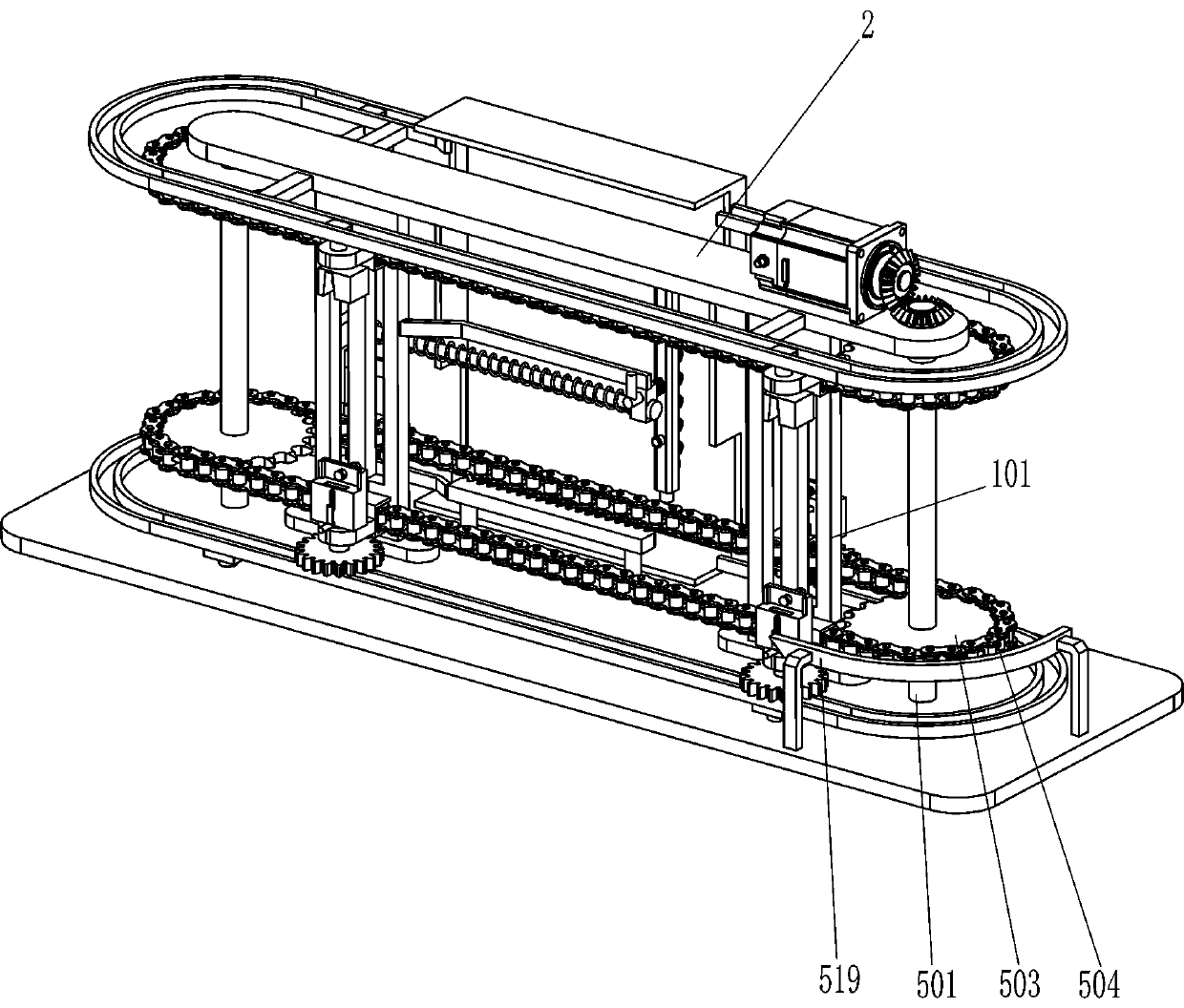

[0022] see Figure 1-Figure 5 , a kind of pick automatic painting equipment, including a base plate 1, a support plate 101, a frame 2, a servo motor 3, a first bevel gear 4, a moving assembly 5 and a painting assembly 6, and the middle parts of the front and rear sides of the top of the base plate 1 are fixed. There is a support plate 101, and the frame 2 is fixedly connected between the tops of the support plates 101 on the front and rear sides. The front side of the top of the frame 2 is connected with a servo motor 3 by means of bolts, and the output shaft of the servo motor 3 is connected by a coupling. There is a first bevel gear 4, a mobile assembly 5 that can place a pick between the top of the bottom plate 1 and the frame 2, and a painting assembly 6 on the rear support plate 101, which cooperates with the mobile assembly 5.

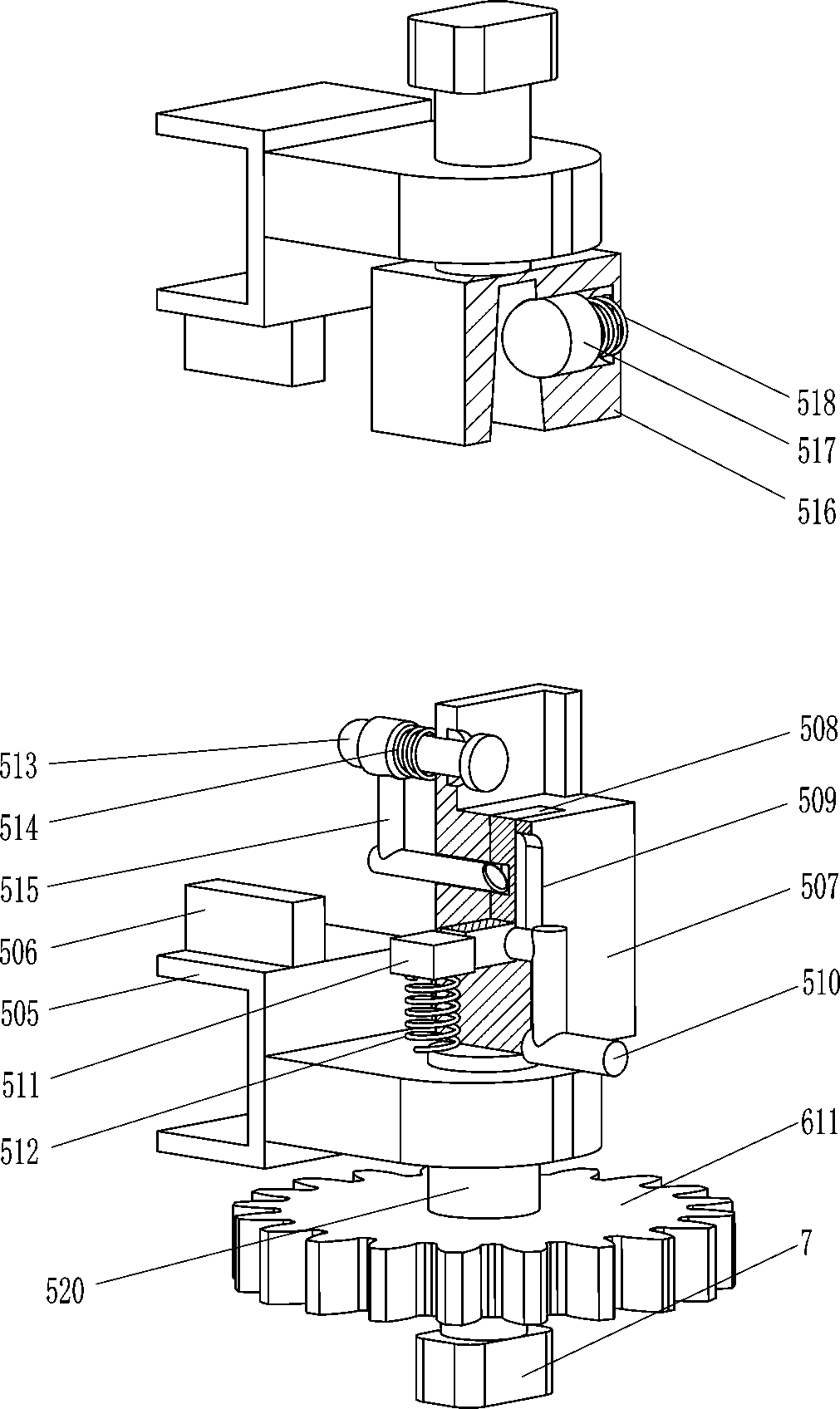

[0023]The moving assembly 5 includes a rotating shaft 501, a second bevel gear 502, a sprocket 503, a chain 504, a mounting block 505, a pushing...

Embodiment 2

[0029] see figure 1 , image 3 and Figure 4 The main difference between this embodiment and embodiment 1 is that in this embodiment, a guide block 7, a first guide rail 8 and a second guide rail 9 are also included, and the outer surface of the frame 2 is circumferentially fixed with a second guide rail. rail 9, the top of the bottom plate 1 is fixedly connected with the first guide rail 8, the first guide rail 8 is located below the chain 504, and the outer ends of the upper and lower sides of the rotating rod 520 are fixedly connected with the guide block 7, and the lower guide block 7 and the first guide rail 8, and the upper guide block 7 cooperates with the second guide rail 9.

[0030] When the installation block 505 drives the rotating rod 520 to reverse, the rotating rod 520 reverses and also drives the guide block 7 to reverse, and then after the pick painting is completed, the guide block 7 also reverses to the first guide rail 8 and the second guide rail 9, when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com