Method for detecting content of bisphenol A

A determination method and content technology, applied in the field of determination of bisphenol A content, to achieve the effect of easy implementation, reliable implementation and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 The drawing of standard curve

[0058] Accurately weigh 12.56 mg of bisphenol A standard substance (purity 99.5% Dr. Ehrenstorfer), dissolve it in acetone-dichloromethane (volume ratio 1:1) and set the volume to 25.0 mL, with a concentration of 500 mg / L as the stock solution, and use acetone- Dichloromethane (volume ratio 1:1) was diluted 50 times to a concentration of 10 mg / L, and then diluted to 0.20, 0.50, 1.00, 2.00, 5.00 mg / L standard solutions.

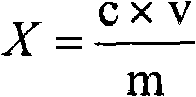

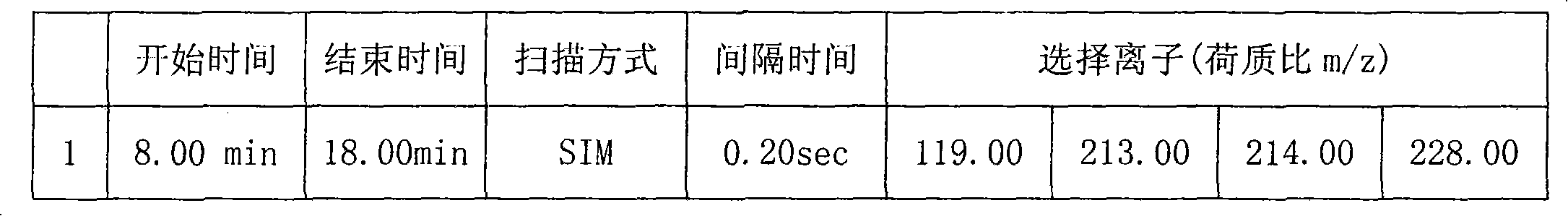

[0059] Use gas chromatography-mass spectrometry to detect the above-mentioned standard liquid for use, take the quantitative ion (M / Z 119) chromatographic peak area as the ordinate, and draw the standard curve with the concentration of the standard liquid for abscissa. The linear equation of the standard curve is Y=6509.95X 2 +56838.90X, the correlation coefficient is R 2 = 0.9996.

Embodiment 2

[0060] The detection of bisphenol A content in the embodiment 2 ABS plastics

[0061] Preparation of sample test solution: Take 1.0 g of crushed ABS plastic solid (accurately weighed to 0.0001 g), put it in a Soxhlet extractor, add 40 mL of acetone-dichloromethane (volume ratio 1:1), and the temperature is 90 ° C Reflux for 10 cycles; take out and cool to room temperature, transfer the extraction solution into a 250mL pear-shaped bottle and wash the container with acetone-dichloromethane (volume ratio 1:1). Concentrate on a rotary evaporator to 1mL test solution, pass through BOND ELUT C18 extraction column (specification: 500mg / 6ml) to purify, use 15mL acetone-dichloromethane (volume ratio 1:1) to rinse, collect eluent. Rotary evaporation The volume of the solution was up to 1ml, and the volume was adjusted to 2mL with acetone-dichloromethane (volume ratio 1:1), and filtered with a 0.45 μm organic phase filter membrane to obtain the sample test solution.

[0062] Repeat the ...

Embodiment 3

[0066] The mensuration of bisphenol A content in the embodiment 3 silicone rubbers

[0067] Preparation of sample test solution: Take 1.0 g of crushed silicone rubber solid sample (accurately weighed to 0.0001 g), put it in a Soxhlet extractor, add 60 mL of acetone-dichloromethane (volume ratio 1:1), and the temperature is 100 ° C Reflux for 15 cycles; take out and cool to room temperature, transfer the extraction solution into a 250mL pear-shaped bottle and wash the container with acetone-dichloromethane (volume ratio 1:1). Concentrate on a rotary evaporator to 1 mL of the test solution, pass through a BOND ELUT C18 extraction column (specification: 500 mg / 6 ml) for purification, rinse with 10 mL of acetone-dichloromethane (volume ratio 1:1), and collect the eluate. The volume of the solution was rotary evaporated to 1ml, and the volume was adjusted to 2mL with acetone-dichloromethane (volume ratio 1:1), and filtered with a 0.45 μm organic phase filter membrane to obtain the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com