General water-based quick-drying anti-rust paint and preparation method thereof

A general-purpose technology for anti-rust paint, applied in anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve problems such as poor low-temperature curing, endangering human health, and low safety, and achieve super flexibility of the paint film, Protect your health and ensure the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

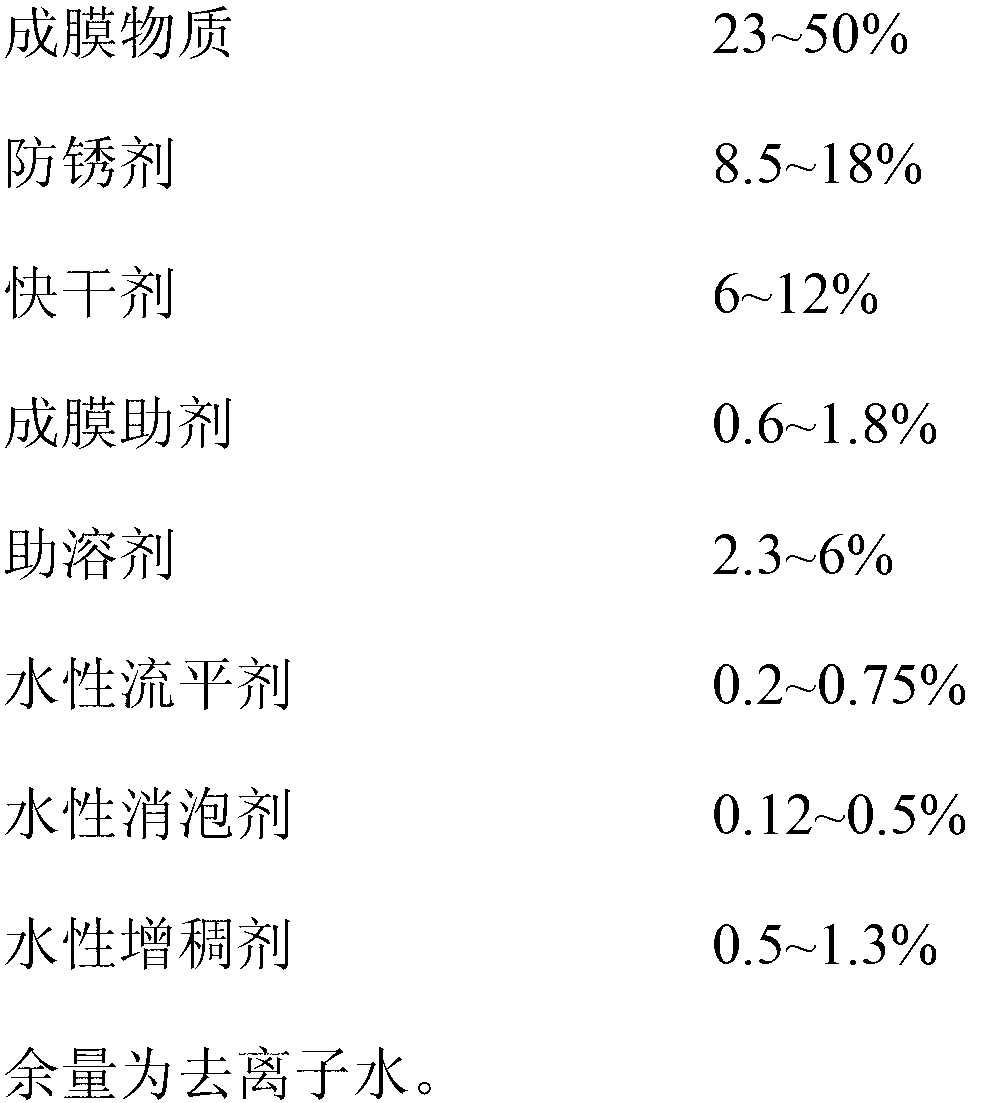

[0054] A general-purpose water-based quick-drying antirust paint, said antirust paint comprises the following components by mass percentage:

[0055]

[0056] First, pre-disperse the other components except the anti-rust agent according to the formula amount for 45 minutes, then add the anti-rust agent according to the formula amount, and re-disperse for 18 minutes, finally dilute with deionized water, filter and pack to obtain a general-purpose water-based quick-drying anti-rust paint.

Embodiment 2

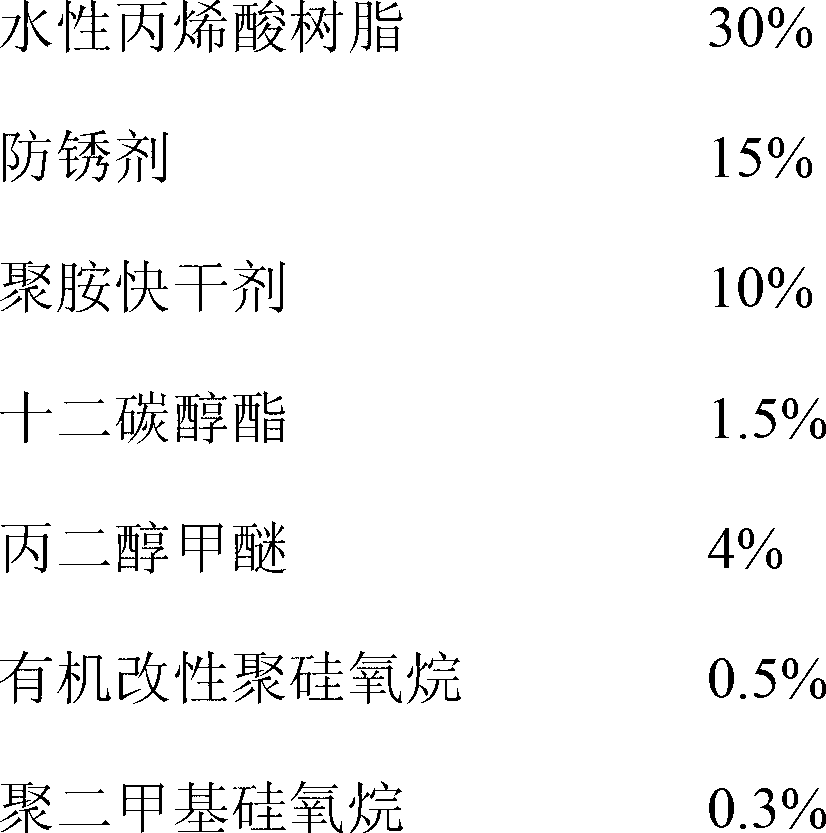

[0058] A general-purpose water-based quick-drying antirust paint, said antirust paint comprises the following components by mass percentage:

[0059]

[0060] First, pre-disperse the other components except the anti-rust agent according to the formula amount for 15 minutes, then add the anti-rust agent in the formula amount, re-disperse for 3 minutes, and finally dilute with deionized water, filter and pack to obtain a general-purpose water-based quick-drying anti-rust paint.

Embodiment 3

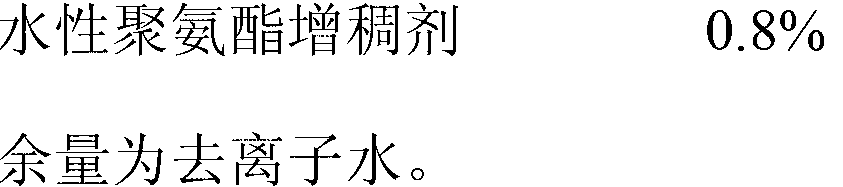

[0062] A general-purpose water-based quick-drying antirust paint, said antirust paint comprises the following components by mass percentage:

[0063]

[0064] First, pre-disperse other components except the anti-rust agent according to the formula amount for 22 minutes, then add the anti-rust agent according to the formula amount, and re-disperse for 6 minutes, finally dilute with deionized water, filter and pack to obtain a general-purpose water-based quick-drying anti-rust paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com