Pulse-type filter cylinder dedusting and ventilating apparatus

A ventilation device and a pulsed technology, applied in the field of pulsed filter cartridge dust removal ventilation devices, can solve problems such as polluting the environment, failing to achieve the effect of vacuuming and dust removal, and safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

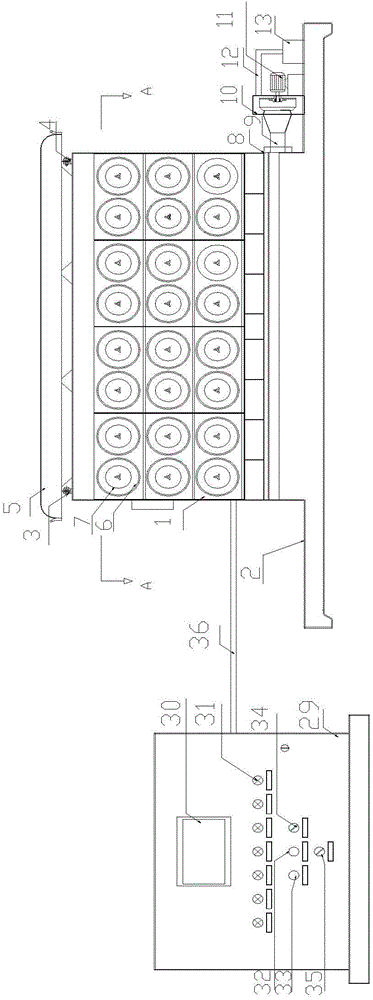

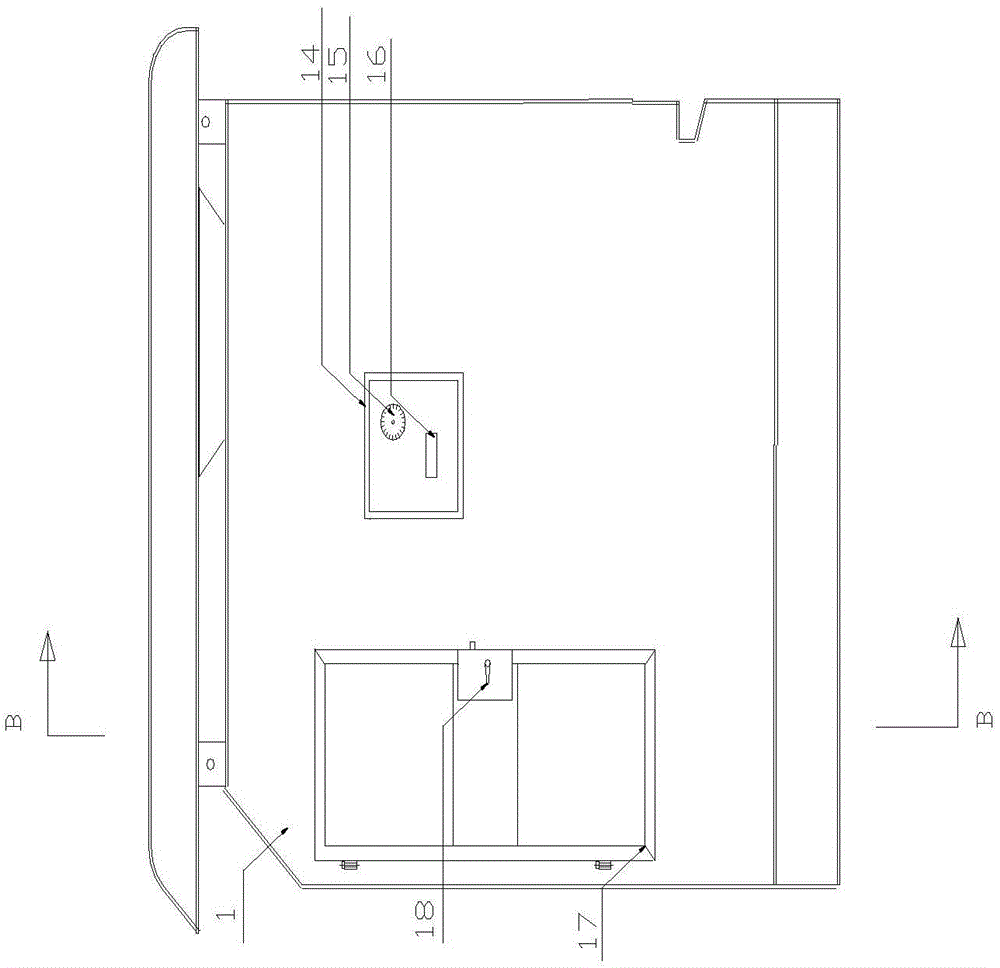

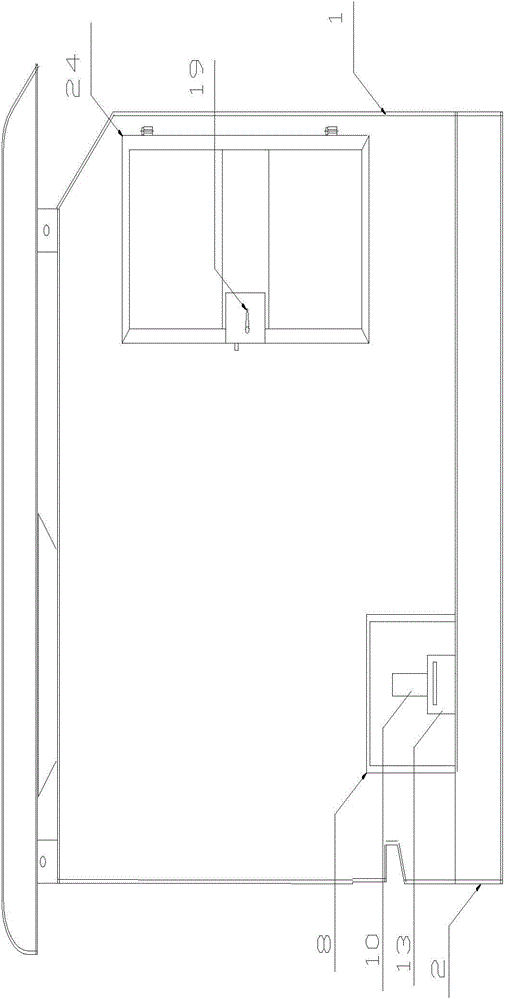

[0021] figure 1 , 2 , 3, 4, and 5 are the structural diagrams of the pulse filter cartridge dust removal and ventilation device. The positions and connections of each part must be correct and the installation should be firm.

[0022] The pulse type filter cartridge dust removal and ventilation device is a horizontal rectangular body, the dust removal box 1 is rectangular, the lower part of the dust removal box 1 is the base 2, and the upper part is provided with the first support plate 3 and the second support plate 4, and supports and connects the air inlet cover 5. There are filter cartridge grooves 6 on the front of the dust removal box 1, and there are 24 filter cartridge grooves 6 in 3 rows, and two filter cartridges 7 are installed in each leakage cartridge groove 6, and there are 48 filter cartridges 7 in total; on the left side of the dust removal box 1 The side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com