Glazing-free high-temperature baked finishing coat for sharing bicycle and preparation method thereof

A technology of sharing bicycles and varnishing, applied in the field of coatings, can solve the problems of high energy consumption and high cost, achieve low VOC content, reduce energy consumption and cost, and reduce VOC emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

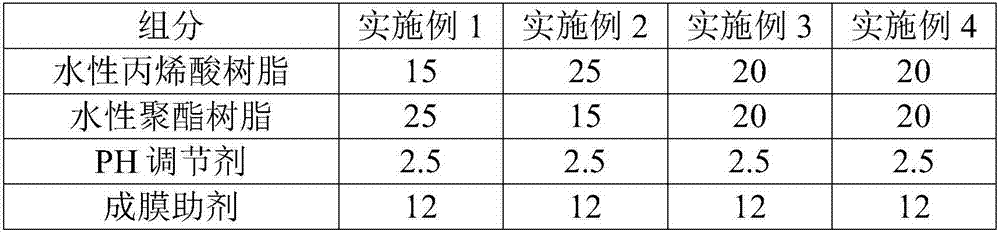

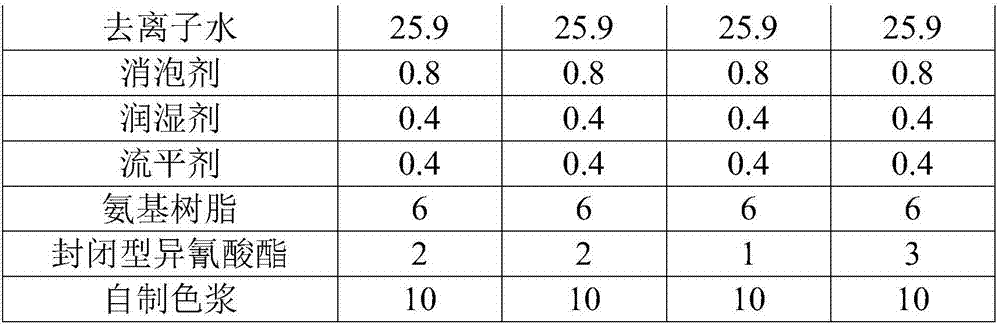

Examples

preparation example Construction

[0046] The preparation method of described embodiment 1-4 is as follows:

[0047] Step 1, taking each component according to the above-mentioned raw material ratio;

[0048] Step 2, adding water-based acrylic resin and water-based polyester resin into the reactor, at a speed of 400-600rpm, adding film-forming aids and pH regulators in turn, and stirring for 5-10min;

[0049] Step 3, add deionized water, defoamer, wetting agent, and leveling agent to the reactor in sequence, and stir at a speed of 400-600rpm for 5-10min to obtain a paint slurry, which is checked with a scraper to see if there is any Shrinkage cavity, if there is stirring at a speed of 800-1000rpm for 10-15min, then proceed to step 4;

[0050] Step 4, at a rotating speed of 600-800rpm, add amino resin, blocked isocyanate, and self-made color paste in sequence, stir for 15-20min, and filter to obtain the gloss-free high-temperature baking finish for the shared bicycle.

[0051] The performance testing results o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com