Polyvinylidene chloride copolymer emulsion for pharmaceutical packing coating and preparation method and application thereof

A technology of polyvinylidene chloride and copolymer emulsion, applied in the field of polyvinylidene chloride copolymer emulsion, which can solve the problems of insufficient stability of latex emulsion, defects of emulsion stability, insufficient emulsion stability, etc., and achieve less foam and low cost , Excellent softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

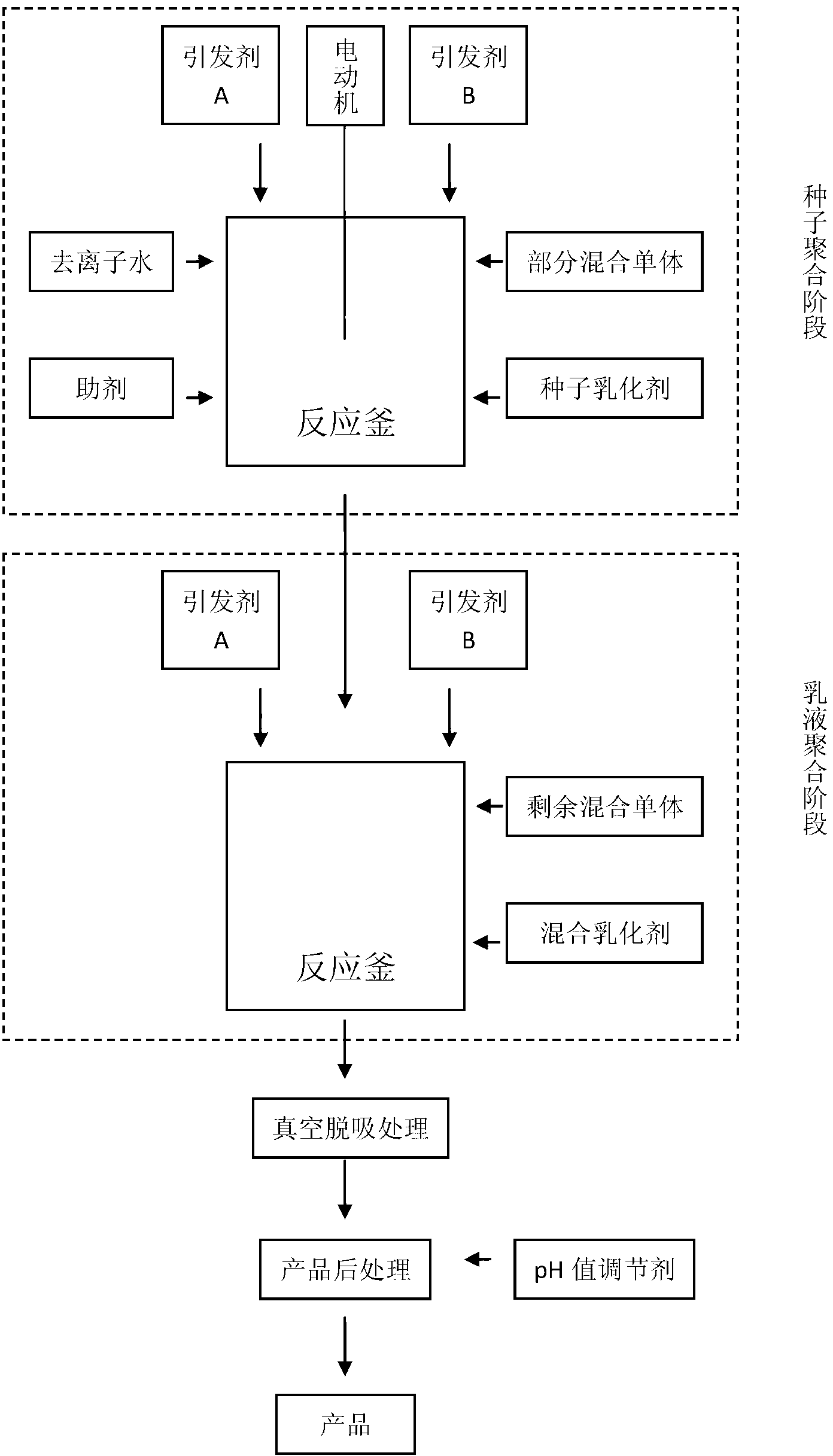

Method used

Image

Examples

Embodiment 1

[0053]1. Raw material preparation: Mix 108kg of vinylidene chloride, 6kg of 2-ethylhexyl acrylate, 5.4kg of butyl methacrylate, and 0.6kg of methacrylic acid, and stir for 2 hours to make a mixed monomer; mix tert-butyl Add 160 g of hydrogen peroxide into 8 kg of deionized water and stir and mix to make a tert-butyl hydroperoxide solution; add 160 g of sodium formaldehyde sulfoxylate to 8 kg of deionized water and stir and mix to make a solution of sodium formaldehyde sulfoxylate; Add 1500g of sodium sulfonate emulsifier, 800g of 2A-1 emulsifier, and 2kg of COPS-1 emulsifier into water and mix, add deionized water to 20kg, and carry out cold dispersion for 2 hours to make a mixed emulsifier solution;

[0054] 2. Seed polymerization: 50kg of deionized water or soft water, 24g of auxiliary ammonium acetate, 5g of ferrous chloride, 150g of sodium dodecylbenzenesulfonate and 400g of MA-80 emulsifier, and seal the kettle. Nitrogen replacement for 3 times, vacuuming, inhalation of 3...

Embodiment 2

[0065] 1. Preparation of raw materials: Mix 112.8kg of vinylidene chloride, 4.08kg of 2-ethylhexyl acrylate, 2.76kg of ethyl methacrylate, and 0.36kg of methacrylic acid, and stir for 2 hours to make a mixed monomer; Add 160 g of butyl hydroperoxide into 8 kg of deionized water and stir and mix to make tert-butyl hydroperoxide solution; add 160 g of sodium formaldehyde sulfoxylate into 8 kg of deionized water and stir and mix to make sodium formaldehyde sulfoxylate Solution: add 1800g of sodium dodecylsulfonate, 900g of MA-80 emulsifier, and 2.2kg of COPS-1 emulsifier into water and mix, add deionized water to 20kg for cold dispersion for 2 hours, and make a mixed emulsifier solution;

[0066] 2. Seed polymerization: 50kg of deionized water or soft water, 24g of auxiliary ammonium acetate and 5g of ferrous chloride, 150g of sodium dodecylbenzenesulfonate and 400g of 2A-1 emulsifier are used to seal the seed emulsifier. Nitrogen replacement for 3 times, vacuuming, inhalation of...

Embodiment 3

[0069] 1. Preparation of raw materials: Mix 111.6kg of vinylidene chloride, 5.04kg of 2-ethylhexyl acrylate, 2.76kg of methyl methacrylate, and 0.6kg of methacrylic acid, and stir for 2 hours to make a mixed monomer; Add 160 g of butyl hydroperoxide into 8 kg of deionized water and stir and mix to make tert-butyl hydroperoxide solution; add 160 g of sodium formaldehyde sulfoxylate into 8 kg of deionized water and stir and mix to make sodium formaldehyde sulfoxylate Solution: Add 1700g of sodium dodecylbenzenesulfonate, 700g of 2A-1 emulsifier, and 3kg of COPS-1 emulsifier into water and mix, add deionized water to 20kg for cold dispersion for 2 hours, and make a mixed emulsifier solution;

[0070] 2. Seed polymerization: 50kg of deionized water or soft water, 24g of auxiliary ammonium acetate and 5g of ferrous chloride, 150g of sodium dodecylbenzenesulfonate and 400g of 2A-1 emulsifier are used to seal the seed emulsifier. Nitrogen replacement for 3 times, vacuuming, inhalatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com