Preparation method of spherical polyvinylidene chloride resin with micropore structures

A technology of polyvinylidene chloride and microporous structure, which is applied in the field of preparation of spherical polyvinylidene chloride resin, can solve the problems of limited application range of spherical PVDC resin, poor performance and short service life of carbon molecular sieve products, and achieve good market prospects , good mechanical properties and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of spherical polyvinylidene chloride resin with microporous structure, comprising the following steps:

[0025] (1) Preparation of water phase

[0026] Add 100kg of water and 1.5kg of gelatin as an organic dispersant to a 500L pressure reactor (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, three-leaf anchor paddle), and stir evenly to obtain an aqueous phase solution.

[0027] (2) Preparation of oil phase

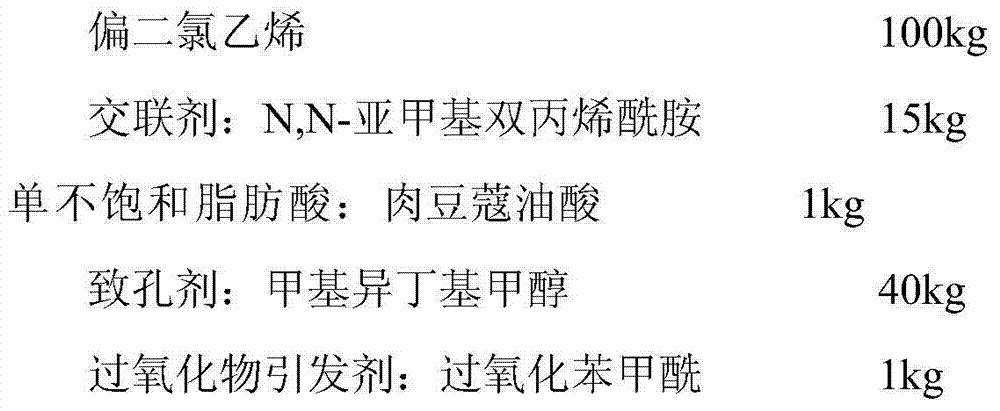

[0028] Add the raw materials of the following composition into a 500L preparation kettle, stir evenly to obtain an oil phase solution;

[0029]

[0030] (3) Suspension polymerization reaction

[0031] Add the oil phase solution prepared in step (2) to the 500L pressure reactor equipped with the prepared water phase in step (1), react at 85°C for 15 hours, discharge the material after the reaction, and wash the microspheres with water until The water is clear, and the porogen is extracted after ...

Embodiment 2

[0033] A preparation method of spherical polyvinylidene chloride resin with microporous structure, comprising the following steps:

[0034] (1) Preparation of water phase

[0035] Add 100kg of water and 0.5kg of polyvinyl alcohol as an organic dispersant to a 500L pressure reactor (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, three-leaf anchor paddle), and stir evenly to obtain an aqueous phase solution.

[0036] (2) Preparation of oil phase

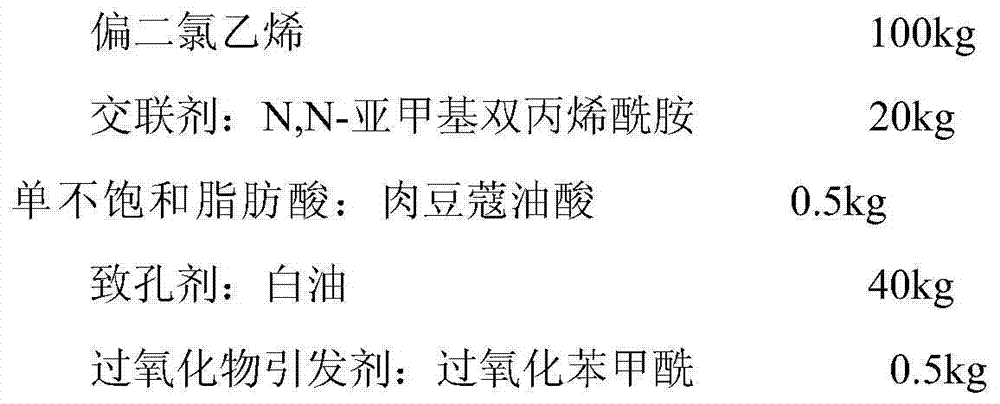

[0037] Add the raw materials of the following composition into a 500L preparation kettle, stir evenly to obtain an oil phase solution;

[0038]

[0039] (3) Suspension polymerization reaction

[0040] Add the oil phase solution prepared in step (2) to the 500L pressure reactor equipped with the prepared water phase in step (1), react at 70°C for 20 hours, discharge the material after the reaction, and wash the microspheres until The water is clear, and the porogen is extracted after d...

Embodiment 3

[0042] A preparation method of spherical polyvinylidene chloride resin with microporous structure, comprising the following steps:

[0043] (1) Preparation of water phase

[0044] Add 100kg of water and 2kg of hydroxymethylcellulose as an organic dispersant to a 500L pressure reactor (stainless steel polymerization kettle with stirring device, length-to-diameter ratio of 2:1, three-leaf anchor paddle), and stir evenly to obtain an aqueous phase solution .

[0045] (2) Preparation of oil phase

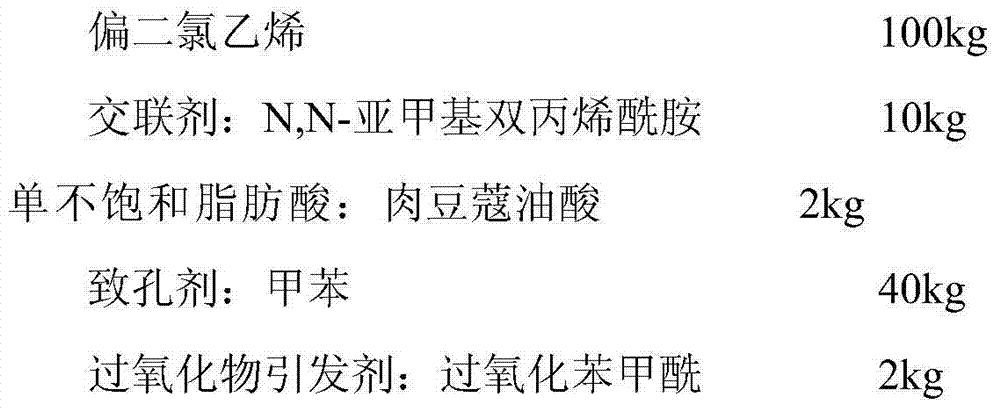

[0046] Add the raw materials of the following composition into a 500L preparation kettle, stir evenly to obtain an oil phase solution;

[0047]

[0048] (3) Suspension polymerization reaction

[0049]Add the oil phase solution prepared in step (2) to the 500L pressure reactor equipped with the prepared water phase in step (1), react at 100°C for 10 hours, discharge the material after the reaction, and wash the microspheres with water until The water is clear, and the porogen is e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com