Oxygen barrier plastic material

An oxygen barrier and oxygen scavenging technology, applied in the field of plastic materials and products, which can solve the problems of poor moisture or UV-Vis activation requirements, compromised film mechanical properties, and lack of clarity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

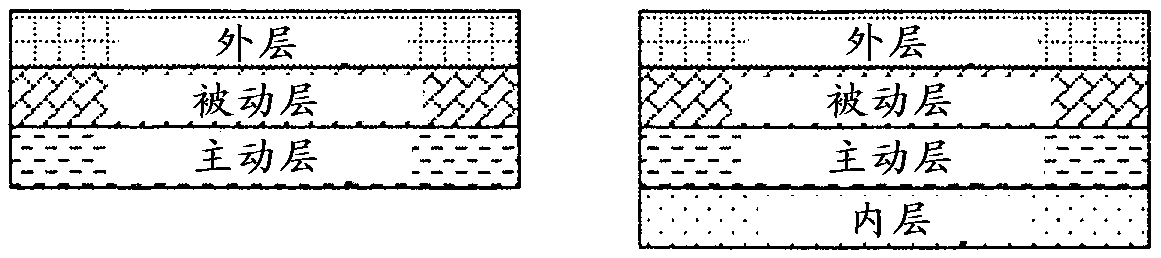

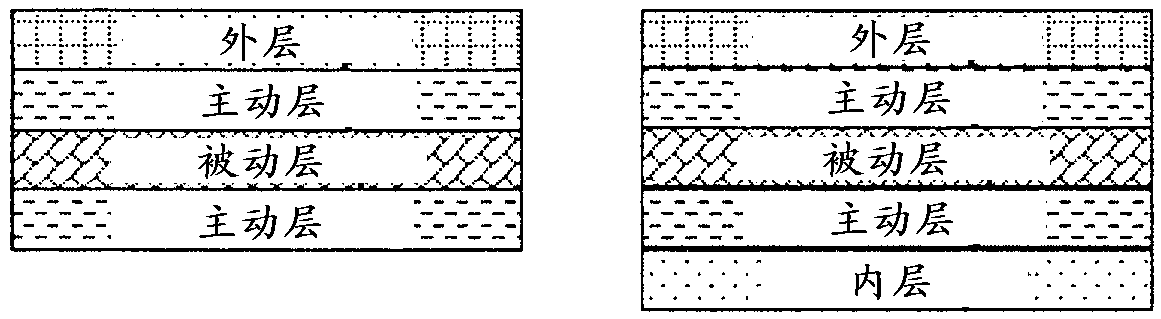

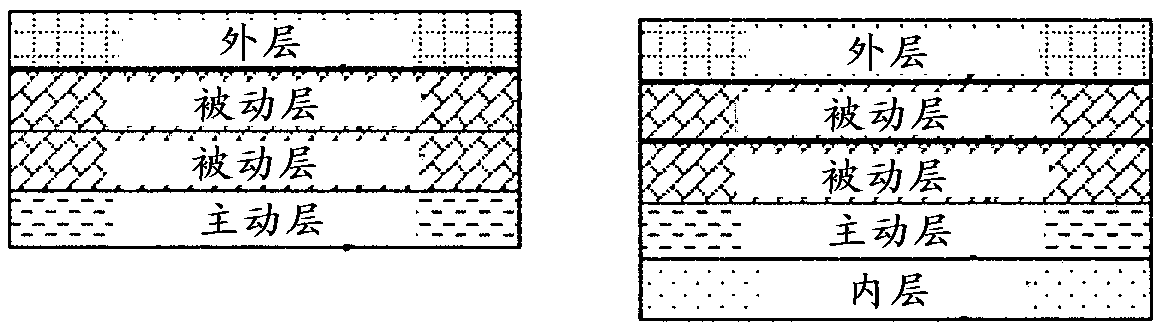

[0146] All produced samples were 107 to 128 μm five-layer cast films with LDPE / bond / EVOH / bond / LDPE structure and respective thicknesses of 50 μm / 6 μm / 5 to 7 μm / 6 μm / 50 μm. This multilayer system is equivalent to figure 1 A three-layer system, but with two additional adhesive layers (tie layers).

[0147]In all constructions the low density polyethylene used is LDPE 2420 (LyondellBasell), whose M.F.I. is 4g / 10min, 190°C, 2.16Kg; the density is (ASTMD3236-88). The ethylene-vinyl alcohol copolymer (EVOH) used is H171B, with an ethylene content of 38mol%, its M.F.I. is 1.7g / 10min, 190°C, 2.16Kg; density is 1.17g / cm 3 (ISO 1183). The binder resin used is AT1707 (Mitsui), its M.F.I. is 4.3g / 10min, 190°C, 2.16Kg; density is 0.91g / cm 3 (ASTM D1505).

[0148] The weight % mentioned in the following examples is based on the total weight of the mixture, composition or product; parts are parts by weight;

[0149] Unless otherwise indicated, "ex" means example; "cpex" mean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com