Poaching type special polyvinyl dichloride (PVDC) rubber latex and preparation method thereof and application

A boiled, latex technology, used in transportation and packaging, flexible coverings, coatings, etc., can solve the problem that polyvinylidene chloride latex cannot meet the boiling resistance and other problems, and achieve the effect of excellent heat sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

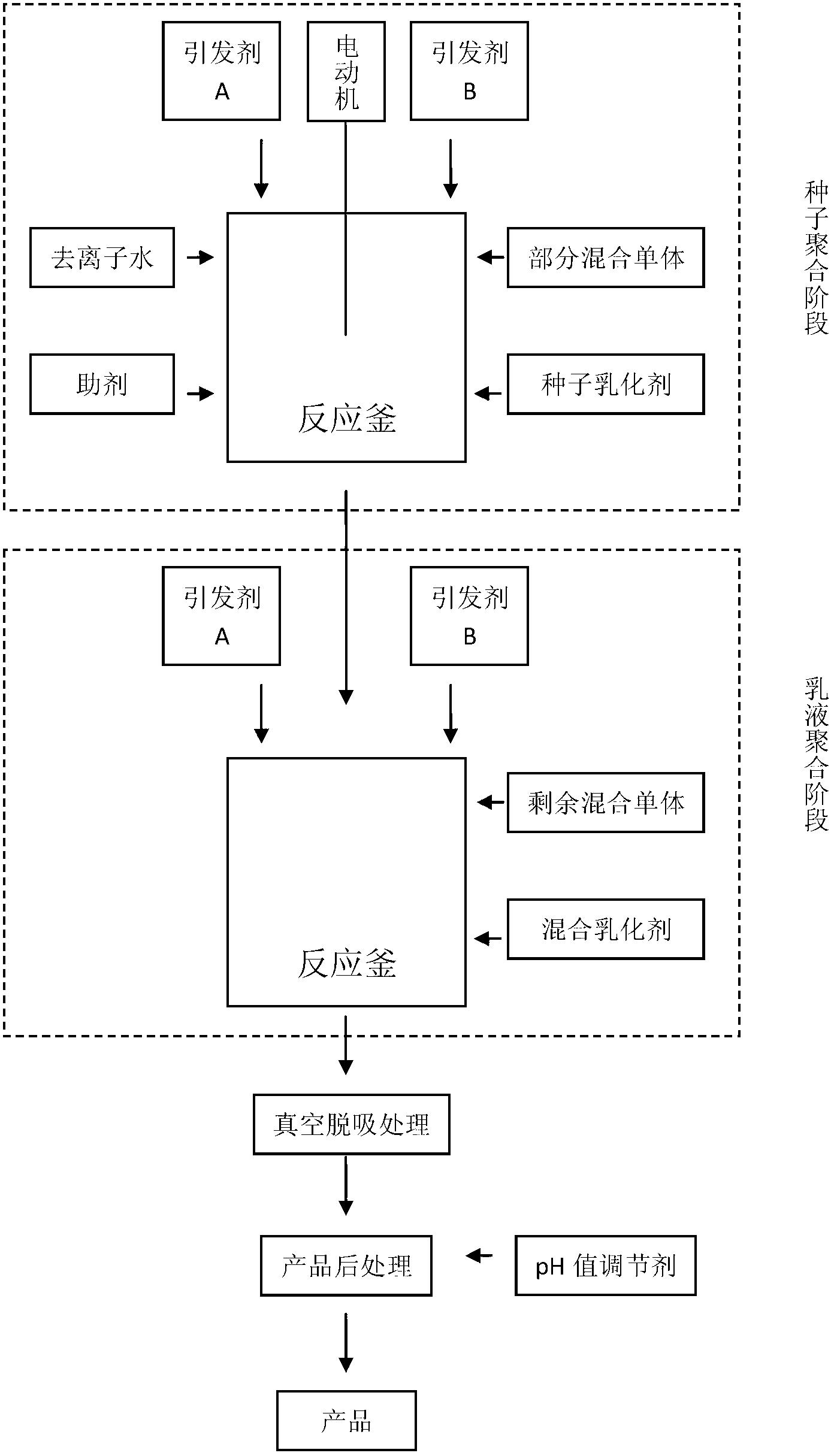

Method used

Image

Examples

Embodiment 1

[0050] 1. Raw material preparation: mix 89.5kg of vinylidene chloride, 1.7kg of (meth)acrylonitrile, 2.5kg of butyl methacrylate, 5.9kg of methyl methacrylate and 0.4kg of methacrylic acid, stir for 2 hours to prepare Mix the monomers; add 160g of tert-butyl hydroperoxide into 8kg of deionized water and stir and mix to make tert-butyl hydroperoxide solution; add 160g of sodium formaldehyde sulfoxylate into 8kg of deionized water and stir and mix to make Sodium formaldehyde sulfoxylate solution; Dissolve 1.2kg of sodium dodecylbenzenesulfonate and 1.2kg of sodium paraffin sulfonate in water, add water to 20kg, and carry out cold dispersion for 2 hours to make a mixed emulsifier solution;

[0051] 2. Seed polymerization: Seal the kettle with 50kg of deionized water or soft water, 24g of additive ammonium acetate, 5g of ferrous chloride, and 180g of sodium dodecylbenzenesulfonate, replace with nitrogen for 3 times, vacuumize, and inhale 3% The mixed monomer is used as a seed mono...

Embodiment 2

[0064] 1. Preparation of raw materials: Mix 92.5kg of vinylidene chloride, 1.2kg of (meth)acrylonitrile, 2.5kg of butyl methacrylate, 3.5kg of methyl methacrylate and 0.3kg of methacrylic acid, and stir for 2 hours to prepare Mix the monomers; add 160g of tert-butyl hydroperoxide into 8kg of deionized water and stir and mix to make tert-butyl hydroperoxide solution; add 160g of sodium formaldehyde sulfoxylate into 8kg of deionized water and stir and mix to make Sodium formaldehyde sulfoxylate solution; Dissolve 1.1kg of sodium dodecylbenzenesulfonate and 1.1kg of sodium paraffin sulfonate in water, add water to 20kg, and carry out cold dispersion for 2 hours to make a mixed emulsifier solution;

[0065] 2. Seed polymerization: Seal the kettle with 50kg of deionized water or soft water, 24g of additive ammonium acetate, 5g of ferrous chloride, and 180g of sodium dodecylbenzenesulfonate, replace with nitrogen for 3 times, vacuumize, and inhale 3% The mixed monomer is used as a s...

Embodiment 3

[0068] 1. Raw material preparation: mix 91kg of vinylidene chloride, 1.6kg of (meth)acrylonitrile, 2.8kg of butyl methacrylate, 4.4kg of methyl methacrylate and 0.2kg of methacrylic acid, stir for 2 hours to make a mixed Monomer; add 160 g of tert-butyl hydroperoxide into 8 kg of deionized water and stir and mix to make tert-butyl hydroperoxide solution; add 160 g of sodium formaldehyde sulfoxylate into 8 kg of deionized water and stir and mix to make formaldehyde Sodium sulfoxylate solution; Dissolve 1.1kg of sodium dodecylbenzenesulfonate and 1.05kg of sodium paraffin sulfonate in water, add water to 20kg, and carry out cold dispersion for 2 hours to make a mixed emulsifier solution;

[0069] 2. Seed polymerization: Seal the kettle with 50kg of deionized water or soft water, 24g of additive ammonium acetate, 5g of ferrous chloride, and 180g of sodium dodecylbenzenesulfonate, replace with nitrogen for 3 times, vacuumize, and inhale 3% The mixed monomer is used as a seed monom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com