Vinylidene chloride copolymer, and its membrane or sheet material

A vinylidene chloride-like copolymer technology, which is applied in the field of vinylidene chloride-like copolymers and compositions thereof, can solve problems such as reducing the incidence of poor packaging, and achieve excellent retort adaptability and excellent stretching process adaptability. , Excellent effect of film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

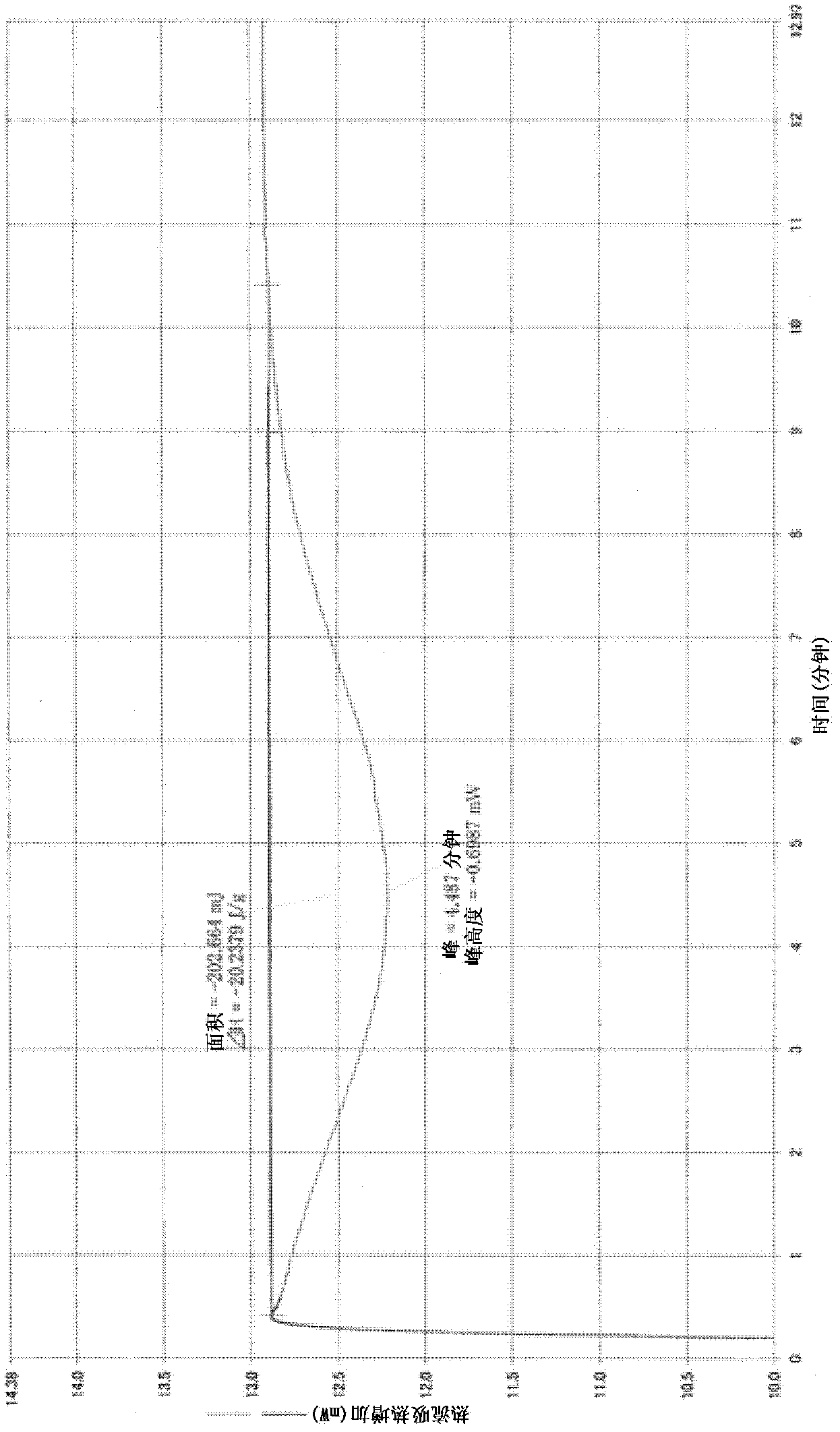

Image

Examples

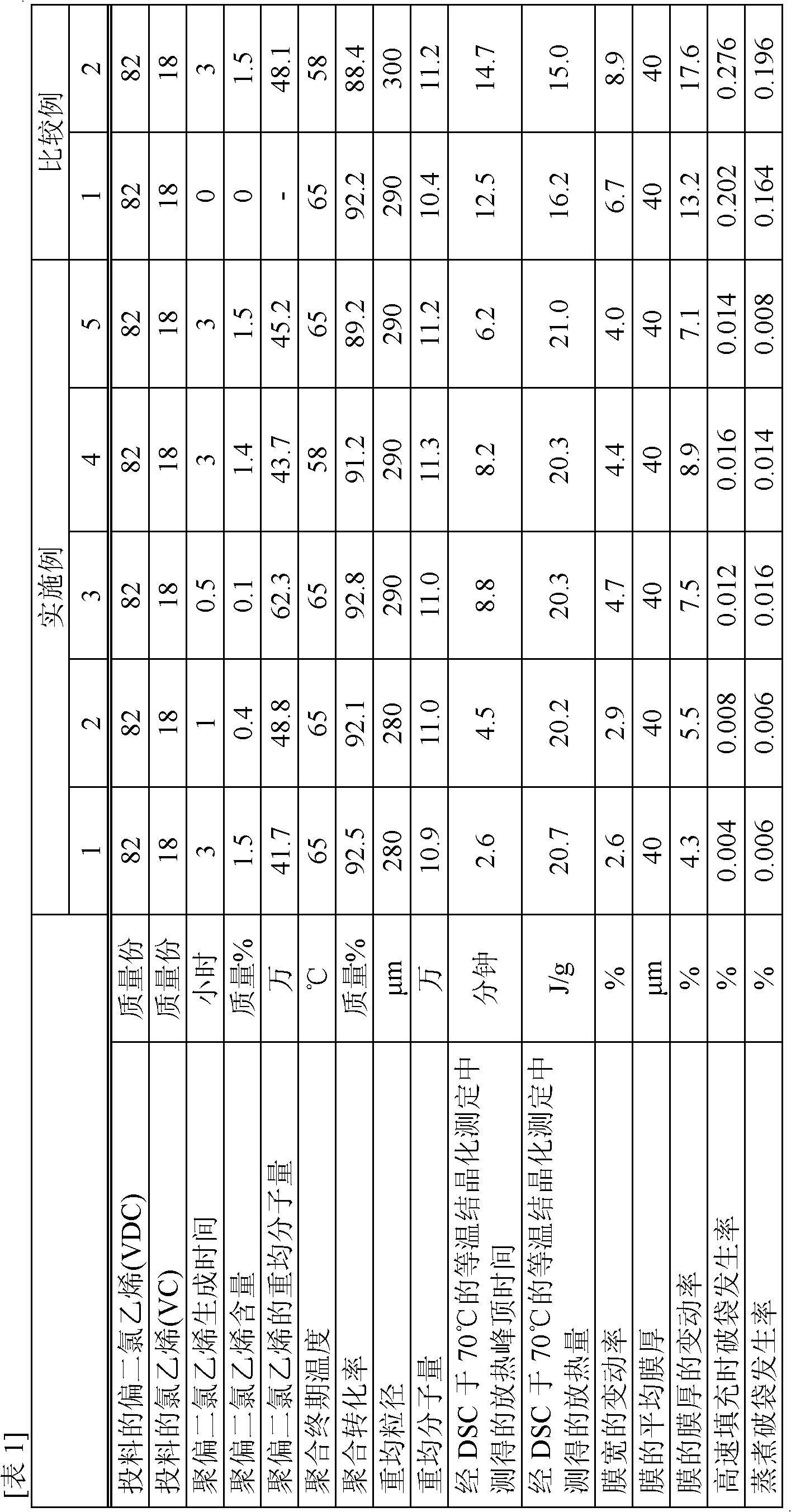

Embodiment 1

[0101] In a glass-lined reactor (inner volume 300L) equipped with three-leaf backward-curved blades (extension diameter: 400mm), finger-shaped baffles, thermometers, and nitrogen inlet pipes, the polymerization initiator was added under a nitrogen atmosphere. Oxidize 0.15 parts by mass (0.17kg) of diisopropyl dicarbonate and 82 parts by mass (90.2kg) of vinylidene chloride (VDC). The mixture was stirred for 3 hours to generate polyvinylidene chloride. Next, 50 g of the mixed solution was taken out immediately before the injection of vinyl chloride, and the amount of polyvinylidene chloride produced and the weight average molecular weight of polyvinylidene chloride were measured.

[0102] Then drop into 18 parts by mass (19.8kg) of vinyl chloride (VC), 0.03 parts by mass (0.03kg) of 3,3-dilauryl thiodipropionate (DLTDP), and carry out the mixed solution with a stirring speed of 1.4m / sec. Stir for 20 minutes. Next, add 100 parts by mass (110 kg) of deionized water and 2.5 part...

Embodiment 2~4

[0108] According to the mass fraction of the vinylidene chloride that feeds feed, the mass fraction of the vinylidene chloride that feeds intake, the generation time of polyvinylidene chloride, the end-of-polymerization temperature according to Table 1, carry out embodiment 2~ 4. The results are listed in Table 1.

Embodiment 5

[0110] Initiate polymerization according to the mass fraction of vinylidene chloride recorded in Table 1, the mass fraction of vinyl chloride fed, and the generation time of polyvinylidene chloride, shorten the polymerization time at the final polymerization temperature of 65°C to Example 5 was carried out in the same manner as in Example 1 except for 6 hours. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com