Vinylidene chloride copolymer, its composition, and its membrane or sheet material

A technology of vinylidene chloride-like copolymers, applied in the field of vinylidene chloride-like copolymers and their compositions, which can solve problems such as reduced productivity and uneven sealing strength, and achieve excellent dimensional stability and uniform film thickness Excellent, non-deformable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

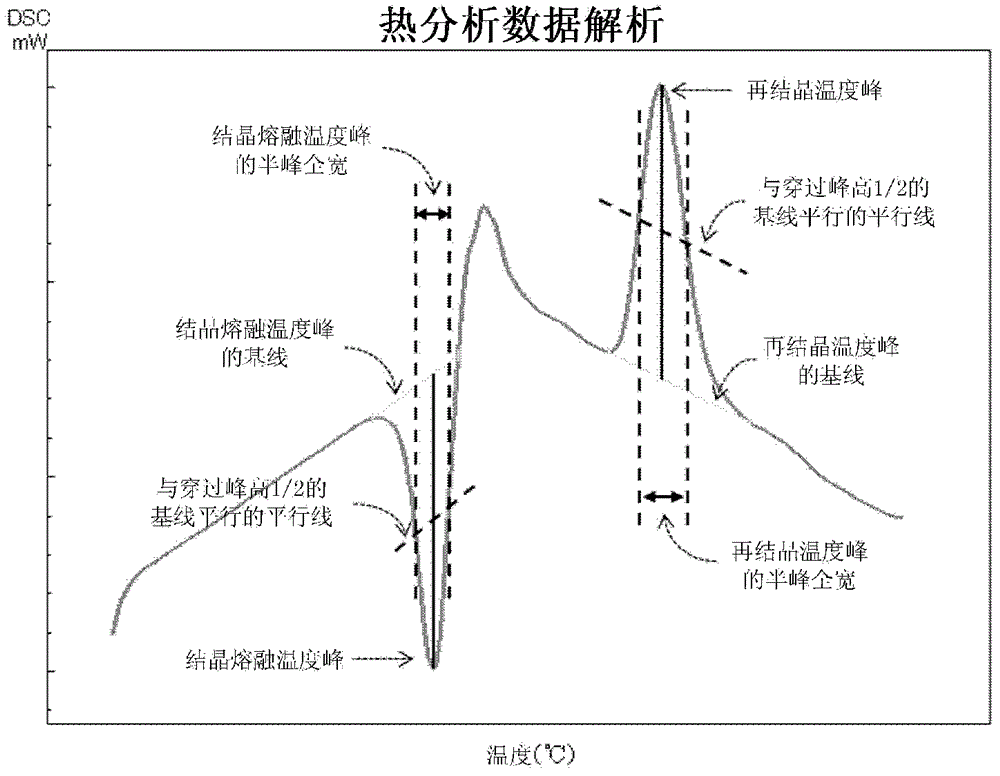

Method used

Image

Examples

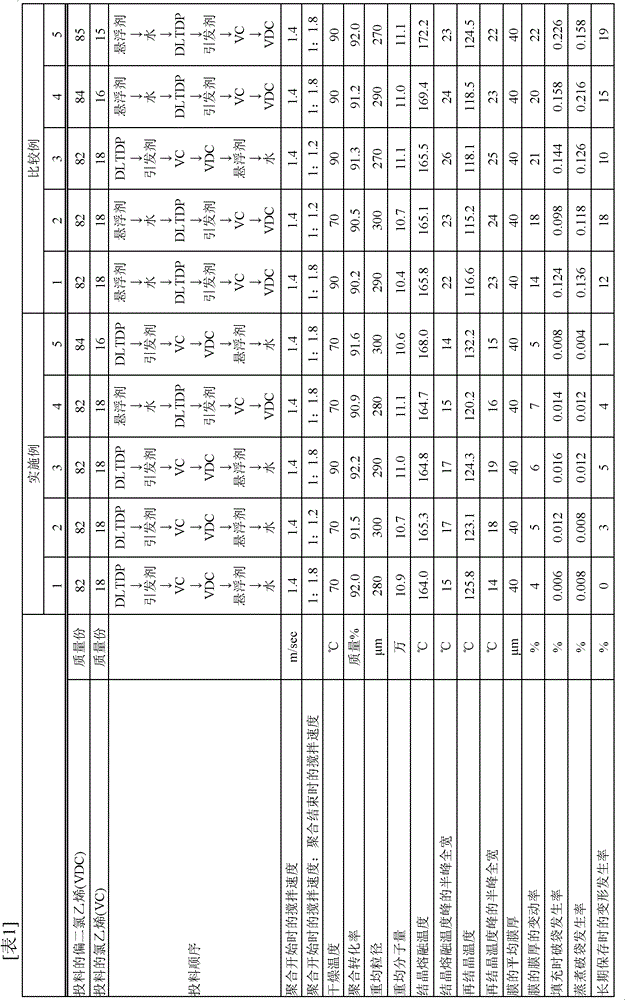

Embodiment 1

[0105] 3,3-Sulfur was introduced into a glass-lined reactor (internal volume 300 L) equipped with three-blade backward-curved blades (400 mm long diameter), a finger baffle, a thermometer, and a nitrogen gas introduction tube (internal volume: 300 L). Dilauryl dipropionate (DLTDP) 0.03 mass parts, polymerization initiator diisopropyl peroxydicarbonate 0.15 mass parts, vinyl chloride (VC) 18 mass parts, vinylidene chloride (VDC) 82 mass parts, with The mixed solution was stirred at a stirring speed of 1.4 m / sec for 20 minutes. Next, 2.5 parts by mass of an aqueous solution with a concentration of 2 mass % of suspending agent hydroxypropyl methylcellulose and 100 parts by mass of deionized water were added, and after stirring for 20 minutes to confirm the formation of particles, the temperature was heated to 35° C. at the initial stage of polymerization in a nitrogen atmosphere. , to initiate polymerization. After the reaction was continued for 15 hours, the stirring speed was ...

Embodiment 2~5

[0111] According to the mass fraction of vinylidene chloride charged in table 1, the mass fraction of vinyl chloride charged, the order of charging, the stirring speed at the start of polymerization, the ratio of stirring speed at the end / start, and the drying temperature, and In Example 1, Examples 2 to 5 were carried out in the same manner. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recrystallization temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com