Vinylidene chloride-based copolymer, its composition, and its film or sheet

A vinylidene chloride and copolymer-like technology, applied in the field of vinylidene chloride-like copolymers and their compositions, can solve the problems of large difference in polymer density, easy segregation and the like, and achieve excellent stretch processing adaptability , excellent cooking adaptability, excellent film thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

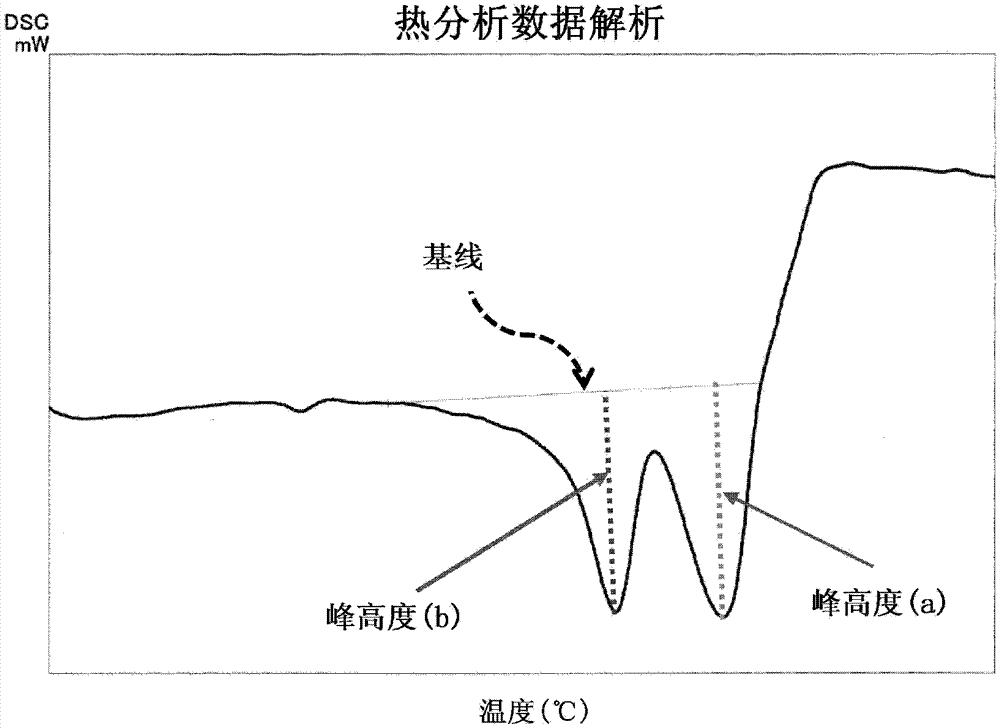

Method used

Image

Examples

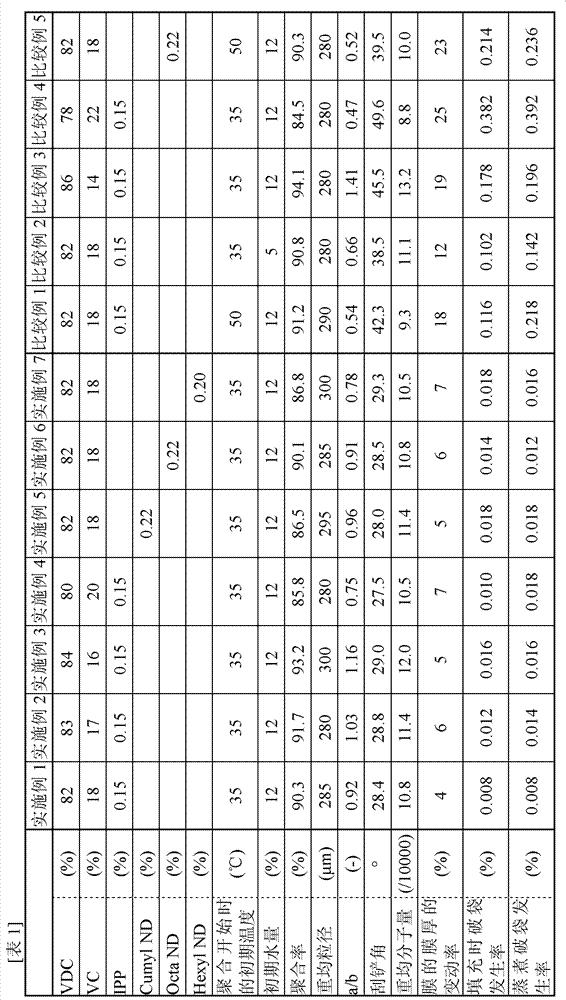

Embodiment 1

[0108] In a glass-lined reactor (inner volume 300L) equipped with three-leaf backward-curved blades (expansion diameter 400mm), finger-shaped baffles, thermometers, and nitrogen inlet pipes, put 12 mass of deionized water in the order described Parts, 0.03 parts by mass of dilauryl 3,3-thiodipropionate (DLTDP), 0.15 parts by mass of polymerization initiator diisopropyl peroxydicarbonate (IPP), 18 parts by mass of vinyl chloride (VC), partial 82 parts by mass of vinyl chloride (VDC), and the mixed solution was stirred for 20 minutes at a stirring speed of 1.4 m / sec. Next, the concentration of the suspending agent hydroxypropyl methylcellulose is 2.5 parts by mass of an aqueous solution of 2 mass%, 88 parts by mass of deionized water, and after stirring for 20 minutes to confirm the formation of particles, the internal temperature of the reactor is raised to Polymerization was initiated at 35°C, and the temperature was continuously raised to 56°C over 30 hours, then maintained a...

Embodiment 2

[0113] Except having changed the addition amount of vinyl chloride (VC) into 17 mass parts, and the addition amount of vinylidene chloride (VDC) into 83 mass parts, it carried out polymerization and evaluated similarly to Example 1. The results are listed in Table 1.

Embodiment 3

[0115] Except having changed the addition amount of vinyl chloride (VC) into 16 mass parts, and the addition amount of vinylidene chloride (VDC) into 84 mass parts, it carried out polymerization and evaluated similarly to Example 1. The results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com