Preparation method of binary acid refined adsorbing material

A technology of adsorption materials and dibasic acids, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems of high loss of dibasic acids, and achieve the effects of improving adsorption capacity, enhancing binding force, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1. Preparation of water phase

[0022] In parts by weight, add 100 parts of pure water and 1.5 parts of gelatin into a 200L reactor, and stir evenly.

[0023] Step 2. Preparation of oil phase

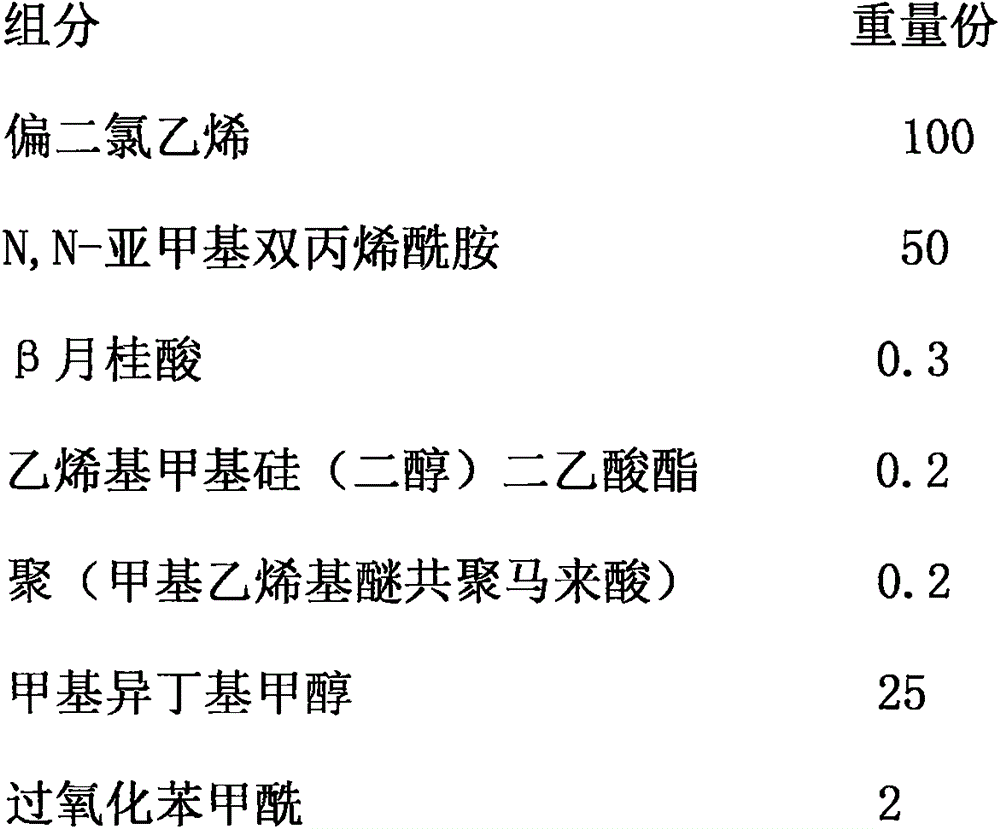

[0024] Mix the oil phase components in the following proportions in a 500L closed reaction kettle and stir evenly;

[0025]

[0026] Step 3. Suspension Polymerization

[0027] Add the prepared water phase solution in step 1 to the airtight reaction kettle with prepared oil phase in step 2, react at 90°C for 15 hours, discharge the material after the reaction is completed, and discharge the material after the reaction, wash the microspheres with water until The water is clear, and the product is obtained, and the obtained product number is SX-1.

Embodiment 2

[0029] Step 1. Preparation of water phase

[0030] In parts by weight, add 100 parts of pure water and 2 parts of gelatin into a 200L reactor, and stir evenly.

[0031] Step 2. Preparation of oil phase

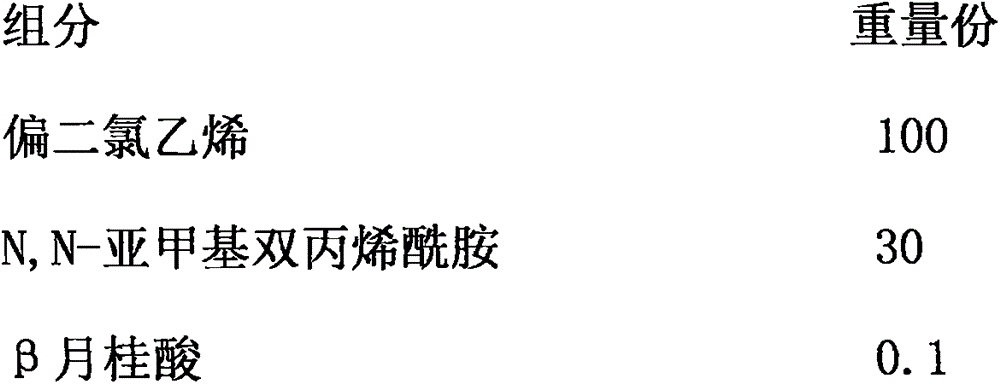

[0032] Mix the oil phase components in the following proportions in a 500L closed reaction kettle and stir evenly;

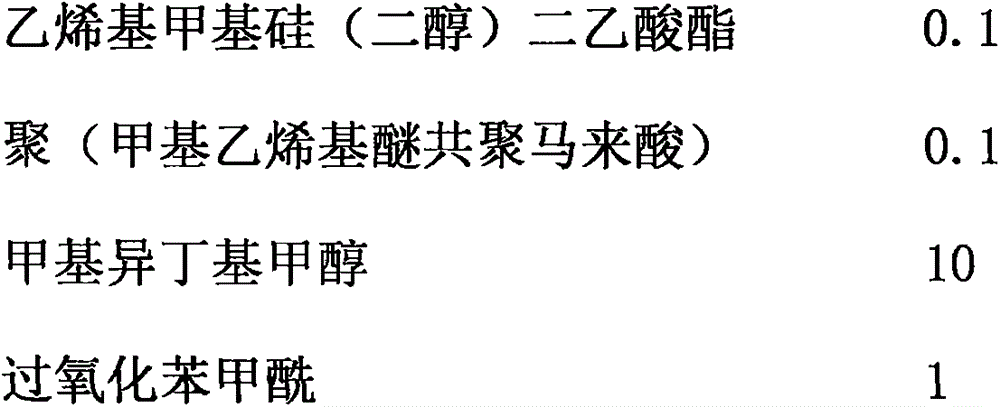

[0033]

[0034]

[0035] Step 3. Suspension Polymerization

[0036] Add the prepared water phase solution in step 1 to the airtight reactor with the prepared oil phase in step 2, react at 110°C for 10 hours, discharge the material after the reaction, and wash the microspheres until The water is clear, and the product is obtained, and the obtained product number is JH-2.

Embodiment 3

[0038] Step 1. Preparation of water phase

[0039] In parts by weight, add 100 parts of pure water and 0.5 parts of gelatin into a 200L reactor, and stir evenly.

[0040] Step 2. Preparation of oil phase

[0041] Mix the oil phase components in the following proportions in a 500L closed reaction kettle and stir evenly;

[0042]

[0043] Step 3. Suspension Polymerization

[0044] Add the prepared water phase solution in step 1 to the airtight reactor with prepared oil phase in step 2, react at 70°C for 20h, discharge after the reaction, discharge after the reaction, wash the microspheres until The water is clear, and the product is obtained, and the obtained product number is JH-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com