Bead polymer for producing PMI foams

A polymer and foam molding technology, applied in the field of foamable bead polymers, can solve the problems of unsuitable suspension polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

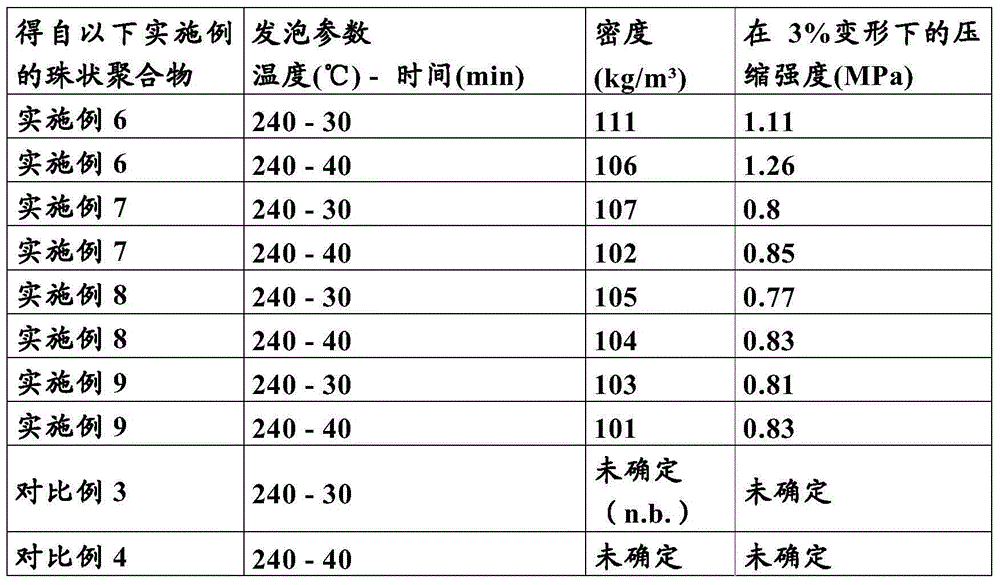

Examples

Embodiment 1

[0050] Aqueous phase: 500.0 g water, 120.0 g sodium sulfate and 7.4 g Degapas 8105S; Mw: 580 000 g / mol; 13.5% strength aqueous solution

[0051] Degapas 8105S is obtained from Polyacrylic acid from Chemiewerke

[0052] Organic phase: 114 g methacrylic acid, 76 g methacrylonitrile, 10 g tert-butyl methacrylate, 0.9 g AIBN, 0.9 g dilauroyl peroxide, 0.2 g tert-butyl per-2-ethylhexanoate

[0053] Water was preliminarily placed in a 1 liter Schmizo reactor with ceramic paddle stirrer, cooler and thermocouple and sodium sulfate was dissolved therein at room temperature. The solution was heated to 75° C. and added dropwise to the monomer phase (solution of monomer and initiator) under stirring (170 rpm) within 35 minutes. The mixture was then stirred at this temperature for a further 1.5 hours. The dispersant was then added dropwise over 2 minutes. An exothermic reaction could be noticed 4 hours after the start of the reaction. The mixture was then stirred at 90 °C for an addi...

Embodiment 2

[0055] Aqueous phase: 706.50 grams of water, 176.47 grams of sodium sulfate, 42.52 grams of Degapas 8105S, 13.5% aqueous solution

[0056] Organic phase: 159.26 g methacrylic acid, 120.14 g methacrylonitrile, 14.70 g tert-butyl methacrylate, 1.28 g AIBN, 1.28 g dilauroyl peroxide, 0.29 g tert-butyl per-2-ethylhexanoate

[0057] Water was preliminarily placed in a 1 liter Schmizo reactor with ceramic paddle stirrer, cooler and thermocouple and sodium sulfate was dissolved therein (internal temperature approximately 75° C.). The ambient air in the reactor was replaced by means of dry ice. The stirring speed was 170 rpm. The organic phase was then added dropwise over 30 minutes. After a reaction time of 2 hours at an internal temperature of about 77°C, the dispersant was added. A slightly exothermic reaction was observed 4 hours after the start of the reaction. The mixed batch was stirred for 1 hour at an internal temperature of 89.5°C. Remove thermocouple. After a post rea...

Embodiment 3

[0060] Example 3: Monomer Mixture Containing Allyl Methacrylate as Crosslinker

[0061] Aqueous phase: 706.50 grams of water, 176.47 grams of sodium sulfate, 42.52 grams of Degapas 8105S; 13.5% aqueous solution

[0062] Organic phase: 164.46 g methacrylic acid, 124.23 g methacrylonitrile, 5.74 g t-butyl methacrylate, 0.294 g allyl methacrylate, 1.28 g AIBN, 1.28 g dilauroyl peroxide, 0.29 g per- tert-butyl 2-ethylhexanoate

[0063] Water was preliminarily placed in a 1 liter Schmizo reactor with ceramic paddle stirrer, cooler and thermocouple and sodium sulfate was dissolved therein (internal temperature approximately 75° C.). The ambient air in the reactor was replaced by means of dry ice. The stirring speed was 170 rpm. The organic phase was then added dropwise over 30 minutes. After a reaction time of 2 hours at an internal temperature of about 77°C, the dispersant was added. After a reaction time of 4 hours (exothermic reaction 79.9°C, bath temperature 79.2°C), the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com