Method for preparing high-density polymethacrylimide foam material

A technology of polymethacrylimide and foam materials, which is applied in the field of preparation of high-density polymethacrylimide foam materials, and can solve problems such as difficulty in obtaining foam plastics, large gas volume, and large density error of foam plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

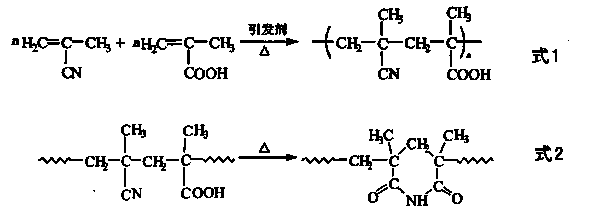

Method used

Image

Examples

Embodiment 1

[0029] A kind of preparation method of high-density polymethacrylimide (PMI) foam material, its formula weight ratio is as follows:

[0030] Methacrylic acid 45

[0031] Methacrylonitrile 45

[0032] Benzoyl Peroxide 0.5

[0033] Azobisisoheptanonitrile 0.05

[0034] N,N-Dimethylurea 6

[0035] Magnesium methacrylate 6

[0036] N.N'-diaminodiphenylmethane type bismaleimide 0.2

[0037] N-Methylformamide 3

[0038] The above-mentioned high-density polymethacrylimide (PMI) foam material preparation method steps are as follows:

[0039] (1) Mix methacrylic acid and methacrylonitrile, add benzoyl peroxide, azobisisoheptanonitrile, N,N-dimethylurea, magnesium methacrylate, N.N'-diamine Mix diphenylmethane bismaleimide and N-methylformamide evenly.

[0040] (2) The solution obtained in step (1) was injected into two parallel glasses sealed by rubber strips, and polymerized in a water bath at 45°C for 60 hours to form a foam precursor copolymerization plate.

[0041] (3) Pre...

Embodiment 2

[0064] A kind of foam material that the preparation method of high-density polymethacrylimide (PMI) foam material obtains, its formula weight ratio is as follows:

[0065] Methacrylic acid 55

[0066] Methacrylonitrile 55

[0067] Benzoyl peroxide 0.6

[0068] Azobisisoheptanonitrile 0.06

[0069] N,N-Dimethylurea 7

[0070] Magnesium methacrylate 7

[0071] N.N'-diaminodiphenylmethane bismaleimide 0.3

[0072] N-Methylformamide 4

[0073] The above-mentioned high-density polymethacrylimide (PMI) foam material preparation method steps are as follows:

[0074] (1) Mix methacrylic acid and methacrylonitrile, add benzoyl peroxide, azobisisoheptanonitrile, N,N-dimethylurea, magnesium methacrylate, N,N-diaminobis Benzene type bismaleimide and N-methylformamide are mixed evenly.

[0075] (2) The solution obtained in step (1) was injected into two parallel glasses sealed by rubber strips, and polymerized in a water bath at 45°C for 60 hours to form a foam precursor copolymeri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com