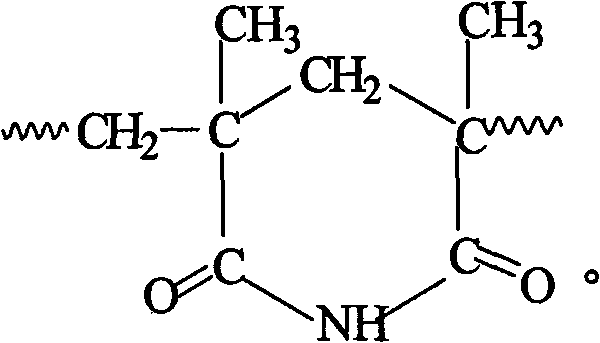

Polymethacrylimide foam material and preparation method thereof

The technology of polymethacrylimide and foam material is applied in the field of polymethacrylimide foam material and its preparation, which can solve the problem of introducing impurities into polymerization inhibitor and reducing the purity of polymethacrylimide foam material. , complex preparation methods, etc., to achieve the effect of reducing production costs, significant economic and social benefits, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Mixing: Mix 15g methacrylic acid, 50g methacrylamide, 0.1g potassium persulfate, 0.8g carbonamide, 0.2g hexanol, 0.1g magnesium methacrylate, and obtain a uniform mixed liquid by magnetic stirring ;

[0038] (2) Pre-polymerization: Pour the uniform mixed liquid into a closed glass container, place the closed glass container in an aqueous solution at 40°C until the liquid in the closed glass container becomes a transparent block;

[0039] (3) Heat treatment: put the transparent block into a vacuum drying oven and keep it at 200°C for 0.5h to obtain a polymethacrylimide foam material.

[0040] The density of the polymethacrylimide foam material that present embodiment prepares is 210kg / m 3 , The tensile strength is 5.46MPa.

Embodiment 2

[0042] (1) Mixing: Mix 90g of acrylic acid, 90g of acrylamide, 3g of potassium persulfate, 2g of sodium thiosulfate, 10g of formamide, 7g of heptanol, 3g of tert-butanol, and 5g of magnesium acrylate, and obtain a uniform mixture by electric stirring liquid;

[0043] (2) Pre-polymerization: Pour the uniform mixed liquid into a closed glass container, place the closed glass container in an aqueous solution at 40°C until the liquid in the closed glass container becomes a transparent block;

[0044] (3) Heat treatment: Put the transparent block into a vacuum drying oven and keep it at 160°C for 6h; then raise the temperature of the vacuum drying oven to 250°C and keep it for 1h, then adjust the temperature of the vacuum drying oven to 160°C and keep it for 6h . A polymethacrylimide foam material was obtained.

[0045] The density of the polymethacrylimide foam material that present embodiment prepares is 81kg / m 3 , the tensile strength is 2.53MPa.

Embodiment 3

[0047](1) Mixing: mix 1g methacrylic acid, 10g acrylic acid, 30g methacrylamide, 20g acrylamide, 3g tert-butyl peroxypivalate, 1g formamide, 3g n-butanol, 6g zinc acrylate, pass Magnetic stirring to obtain a uniform mixed liquid;

[0048] (2) Pre-polymerization: Pour the uniform mixed liquid into a closed glass container, and place the closed glass container in an aqueous solution at 100° C. until the liquid in the closed glass container becomes a transparent block;

[0049] (3) Heat treatment: put the transparent block into a vacuum drying oven and keep it at 100° C. for 2 hours; then raise the temperature of the vacuum drying oven to 170° C. and keep it for 6 hours to obtain a polymethacrylimide foam material.

[0050] The density of the polymethacrylimide foam material that present embodiment prepares is 102kg / m 3 , The tensile strength is 3.26MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com