Method for preparing graphene reinforced PMI (polymethacrylimide) foam material

A polymethacrylimide and foam material technology is applied in the field of preparation of graphene reinforced polymethacrylimide foam materials, which can solve the problems of reducing the tensile strength and modulus mechanical properties of PMI foam, and achieve Excellent deformation mechanism, wide application field, effect of increasing electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

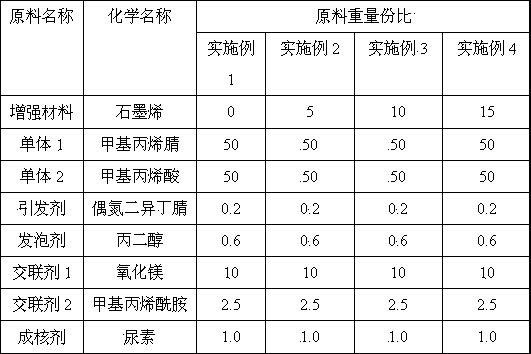

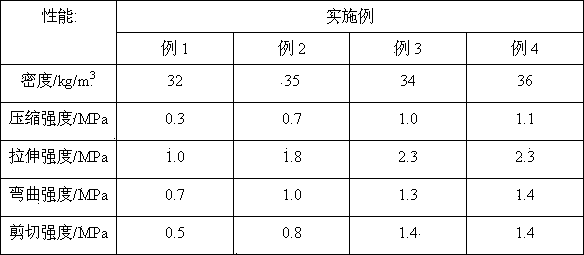

[0029] A kind of preparation method of graphene reinforced polymethacrylimide foam material, graphene reinforced polymethacrylimide foam is made of graphene, monomer, initiator, crosslinking agent, blowing agent, nucleating agent composition. Concrete formula is the formula component weight ratio of example 1,2,3,4 shown in table 1.

[0030]

[0031] Table 1 Examples of graphene-enhanced polymethacrylimide foams

[0032]

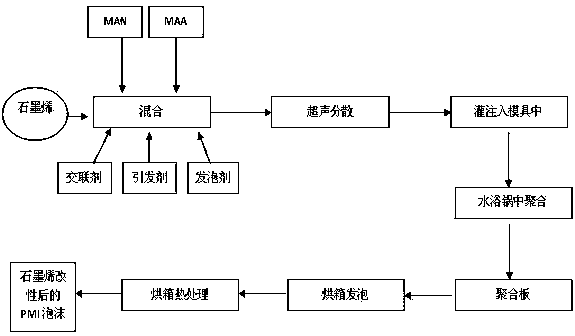

[0033] Concrete preparation steps are as follows:

[0034] (1) Mix monomers, initiators, crosslinking agents, foaming agents, and nucleating agents according to the weight ratios of Examples 1, 2, 3, and 4, and pass through 3000r / min at a water bath temperature of 25°C The speed of the mixer was mixed for 3 hours to stir the reaction solution evenly;

[0035] (2) Add graphene to the raw material solution, place the mixed solution in an ultrasonic disperser at a frequency of 50kHz, and disperse ultrasonically for 50 minutes, so that the graphene can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com