Method for preparing unsaturated nitrile catalyst using with ammoxidation method

An ammonia oxidation method and catalyst technology, which are applied in the preparation of hydrocarbon ammoxidation, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of high carbonyl by-products, high residual ammonia, and low ammonia conversion rate, and achieve residual Effects of low ammonia, low ammonia ratio and residual ammonia, and low reaction temperature

Inactive Publication Date: 2008-02-13

CHINA PETROLEUM & CHEM CORP +1

View PDF9 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~15

[0037] Embodiment Catalyst preparation method is the same as comparative example, just adds following compound in material A:

Embodiment 1、2

[0038] Embodiment 1, 2 grams of trichloroacetic acid

Embodiment 2、50

[0039] Embodiment 2, 50 milliliters of acetic acid

[0040] Embodiment 2, 50 milliliters of acetic acid

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

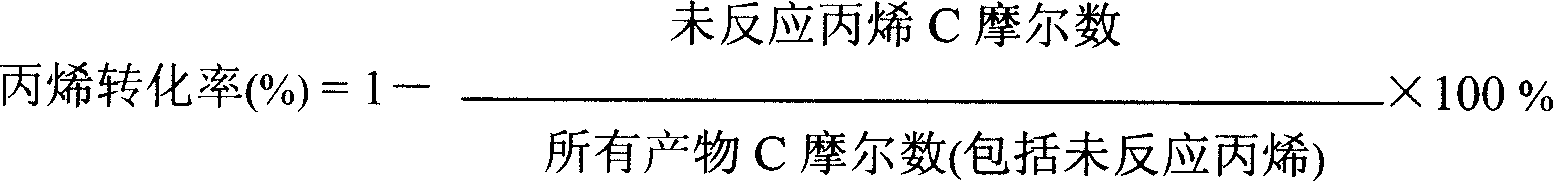

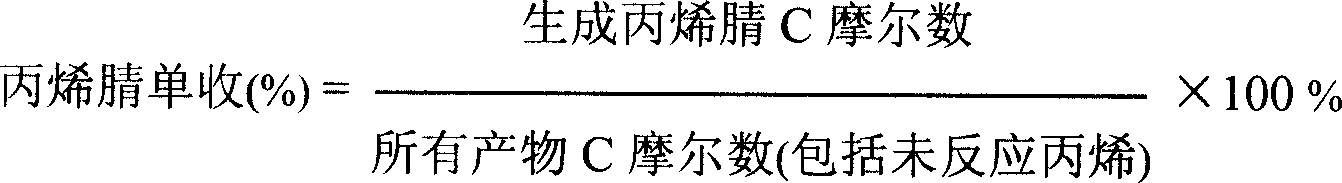

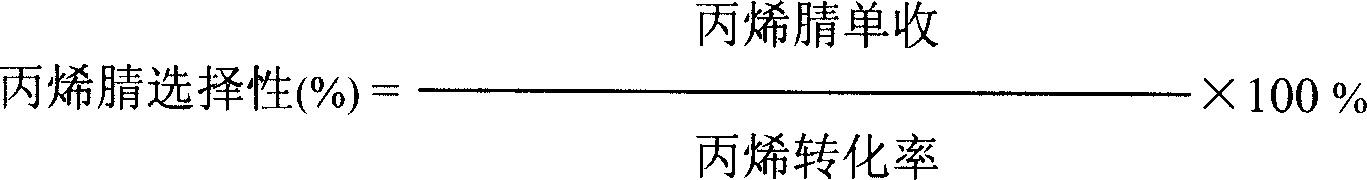

The present invention relates to a preparation method of an unsaturated nitrile catalyst, which is produced by an ammoxidation. The present invention mainly solves the problems in the prior art that in the ammoxidation, an ammonia conversion rate is low; the remnants ammonia is high; carbonyl by-products, such as acrolein etc, are high. The present invention solves the problems well by a technical proposal that SiO2 is used as a carrier, and the catalyst consists of a combination is adopted which contains active components and which is expressed by the following general formula: in the formula of Mo12BiaFebNicXdYeZfOx, the X is selected from at least one of Mg, Co, Ca, Cu, Zn, Pb, Mn, Cr, Nb, Zr, Ti, Sn or Ru; the Y is selected from at least one of La, Ce, Sm or Ge; the Z is selected from at least one of K, Rb, Na, Cs, In, Tl or Ag, and at least one of an organic compound which contains active-oh and can mutually react with a silica sol is added into an initial material in the process of the catalyst preparation. The present invention can be used for the industrial production of unsaturated nitrile, which is produced by an olefin ammoxidation.

Description

technical field [0001] The invention relates to a method for preparing an unsaturated nitrile catalyst by ammoxidation of olefins and olefins. Background technique [0002] The ammoxidation of olefins to prepare α and β unsaturated nitriles was developed by BP in the 1960s. The core technology of this process is to use a catalyst whose active components contain Mo and Bi. After continuous improvement, the Mo-Bi series catalyst is very mature at present, and the process of preparing acrylonitrile by ammoxidation of propylene has been widely used in industry. In the past, the improvement of the catalyst was mainly carried out from the aspects of the activity and stability of the catalyst, such as adding transition metals to the active component to improve the activity and increase the yield of the product; adding rare earth elements to improve the redox ability; adding elements such as Na and P To improve the wear resistance of the catalyst; add Fe, Co, Ni and other elements ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/887B01J23/83B01J23/78B01J21/08C07C255/08C07C253/24

CPCY02P20/52

Inventor 姜家乐杨斌

Owner CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com