Fiber regeneration machine

A regenerator and fiber technology, applied in grain processing and other directions, can solve the problems of reducing material crushing effect, taking longer time, reducing cutting frequency, etc., and achieving the effect of shortening crushing time, reducing energy consumption, and increasing cutting frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

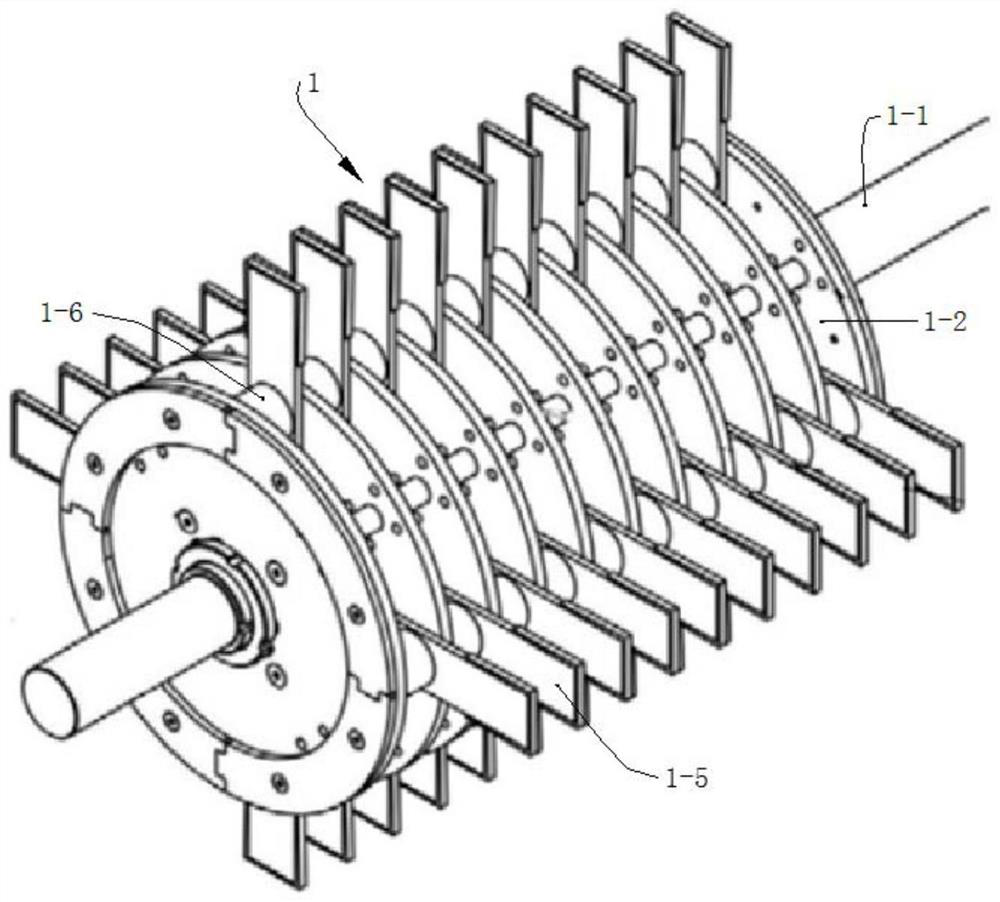

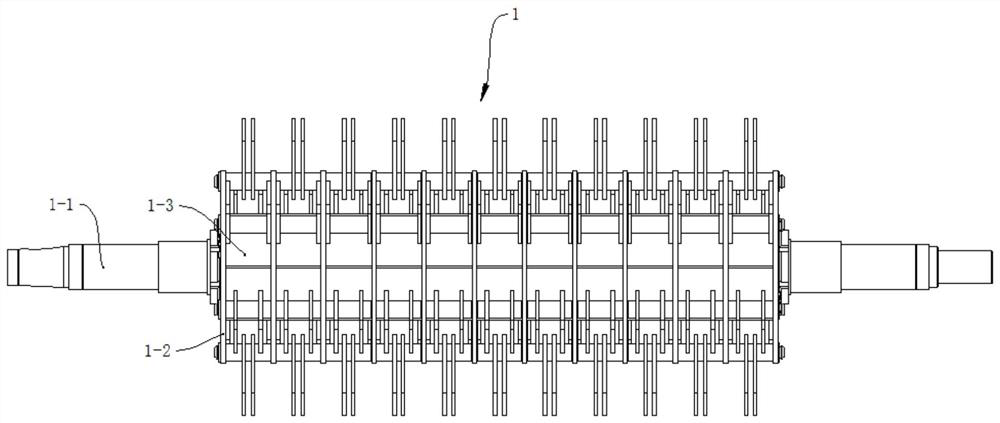

[0063] A fiber recycling machine includes a rotor 1 arranged in a casing 2 .

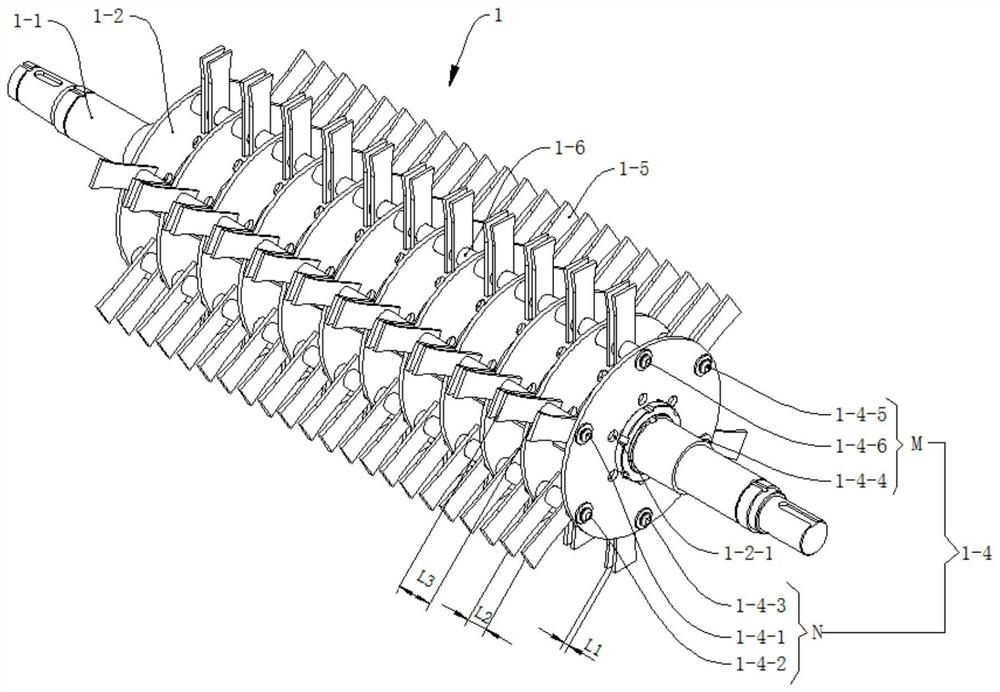

[0064] Such as figure 2 and image 3 As shown, the rotor 1 includes a rotor shaft 1-1, a cutter head 1-2, a shaft pin 1-4, and a blade 1-5.

[0065] Such as figure 2 As shown, there are multiple cutter heads 1-2, and in this embodiment, there are twelve cutter heads 1-2. All cutter heads 1-2 are fixedly mounted on the rotor shaft 1-1 through flat keys or splines. Such as image 3 As shown, a cutterhead spacer 1-3 is installed between two adjacent cutterheads 1-2, and the cutterhead spacer 1-3 is also fixedly installed on the rotor shaft 1-1 through a flat key or a spline. The spacer 1-3 is used to fix the space between two adjacent cutterheads 1-2.

[0066] In order to improve the stability of two adjacent cutterhead spacers 1-3 clamping the cutterhead 1-2, as Figure 4 As shown, a plurality of cutterhead partitions 1-3-1 are welded on the cutterhead spacer 1-3. In this embodiment, three c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com